FIRE DESIGN OF STEEL MEMBERS - Civil and Natural Resources ...

FIRE DESIGN OF STEEL MEMBERS - Civil and Natural Resources ...

FIRE DESIGN OF STEEL MEMBERS - Civil and Natural Resources ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

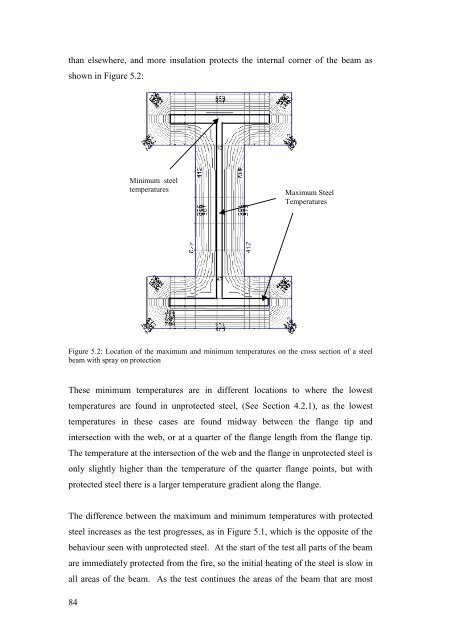

than elsewhere, <strong>and</strong> more insulation protects the internal corner of the beam as<br />

shown in Figure 5.2:<br />

Minimum steel<br />

temperatures<br />

Maximum Steel<br />

Temperatures<br />

Figure 5.2: Location of the maximum <strong>and</strong> minimum temperatures on the cross section of a steel<br />

beam with spray on protection<br />

These minimum temperatures are in different locations to where the lowest<br />

temperatures are found in unprotected steel, (See Section 4.2.1), as the lowest<br />

temperatures in these cases are found midway between the flange tip <strong>and</strong><br />

intersection with the web, or at a quarter of the flange length from the flange tip.<br />

The temperature at the intersection of the web <strong>and</strong> the flange in unprotected steel is<br />

only slightly higher than the temperature of the quarter flange points, but with<br />

protected steel there is a larger temperature gradient along the flange.<br />

The difference between the maximum <strong>and</strong> minimum temperatures with protected<br />

steel increases as the test progresses, as in Figure 5.1, which is the opposite of the<br />

behaviour seen with unprotected steel. At the start of the test all parts of the beam<br />

are immediately protected from the fire, so the initial heating of the steel is slow in<br />

all areas of the beam. As the test continues the areas of the beam that are most<br />

84