TECH - SPEC'S Technician's Pocket Guide - Hoshizaki America, Inc.

TECH - SPEC'S Technician's Pocket Guide - Hoshizaki America, Inc.

TECH - SPEC'S Technician's Pocket Guide - Hoshizaki America, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

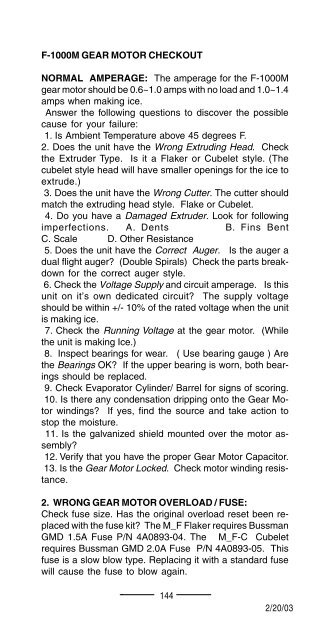

F-1000M GEAR MOTOR CHECKOUT<br />

NORMAL AMPERAGE: The amperage for the F-1000M<br />

gear motor should be 0.6~1.0 amps with no load and 1.0~1.4<br />

amps when making ice.<br />

Answer the following questions to discover the possible<br />

cause for your failure:<br />

1. Is Ambient Temperature above 45 degrees F.<br />

2. Does the unit have the Wrong Extruding Head. Check<br />

the Extruder Type. Is it a Flaker or Cubelet style. (The<br />

cubelet style head will have smaller openings for the ice to<br />

extrude.)<br />

3. Does the unit have the Wrong Cutter. The cutter should<br />

match the extruding head style. Flake or Cubelet.<br />

4. Do you have a Damaged Extruder. Look for following<br />

imperfections. A. Dents B. Fins Bent<br />

C. Scale D. Other Resistance<br />

5. Does the unit have the Correct Auger. Is the auger a<br />

dual flight auger? (Double Spirals) Check the parts breakdown<br />

for the correct auger style.<br />

6. Check the Voltage Supply and circuit amperage. Is this<br />

unit on it’s own dedicated circuit? The supply voltage<br />

should be within +/- 10% of the rated voltage when the unit<br />

is making ice.<br />

7. Check the Running Voltage at the gear motor. (While<br />

the unit is making Ice.)<br />

8. Inspect bearings for wear. ( Use bearing gauge ) Are<br />

the Bearings OK? If the upper bearing is worn, both bearings<br />

should be replaced.<br />

9. Check Evaporator Cylinder/ Barrel for signs of scoring.<br />

10. Is there any condensation dripping onto the Gear Motor<br />

windings? If yes, find the source and take action to<br />

stop the moisture.<br />

11. Is the galvanized shield mounted over the motor assembly?<br />

12. Verify that you have the proper Gear Motor Capacitor.<br />

13. Is the Gear Motor Locked. Check motor winding resistance.<br />

2. WRONG GEAR MOTOR OVERLOAD / FUSE:<br />

Check fuse size. Has the original overload reset been replaced<br />

with the fuse kit? The M_F Flaker requires Bussman<br />

GMD 1.5A Fuse P/N 4A0893-04. The M_F-C Cubelet<br />

requires Bussman GMD 2.0A Fuse P/N 4A0893-05. This<br />

fuse is a slow blow type. Replacing it with a standard fuse<br />

will cause the fuse to blow again.<br />

144<br />

12/01/02 12/20/03<br />

2/20/03