3to 11hp 4-cycle l-head engines - Small Engine Suppliers

3to 11hp 4-cycle l-head engines - Small Engine Suppliers

3to 11hp 4-cycle l-head engines - Small Engine Suppliers

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SERVICE<br />

Service on the polyurethane element (cleaning and oiling) is recommended every three months or every twenty five<br />

operating hours, whichever comes first. Extremely dirty or dusty conditions may require daily cleanings.<br />

The paper filter element should be replaced at least once a year or more frequently if operated in dusty or dirty conditions.<br />

NOTE: NEVER RUN THE ENGINE WITHOUT THE COMPLETE AIR CLEANER ASSEMBLY INSTALLED ON THE<br />

ENGINE. ALWAYS REPLACE THE FILTER ELEMENT WITH THE PROPER TECUMSEH ORIGINAL REPLACEMENT<br />

PART.<br />

DISASSEMBLY PROCEDURE<br />

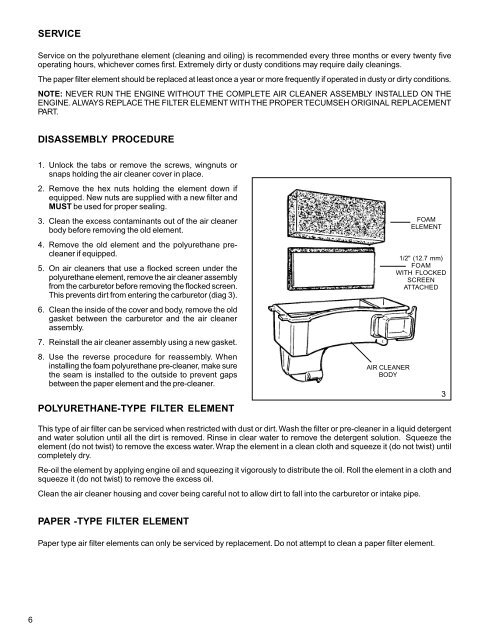

1. Unlock the tabs or remove the screws, wingnuts or<br />

snaps holding the air cleaner cover in place.<br />

2. Remove the hex nuts holding the element down if<br />

equipped. New nuts are supplied with a new filter and<br />

MUST be used for proper sealing.<br />

3. Clean the excess contaminants out of the air cleaner<br />

body before removing the old element.<br />

4. Remove the old element and the polyurethane precleaner<br />

if equipped.<br />

5. On air cleaners that use a flocked screen under the<br />

polyurethane element, remove the air cleaner assembly<br />

from the carburetor before removing the flocked screen.<br />

This prevents dirt from entering the carburetor (diag 3).<br />

6. Clean the inside of the cover and body, remove the old<br />

gasket between the carburetor and the air cleaner<br />

assembly.<br />

7. Reinstall the air cleaner assembly using a new gasket.<br />

8. Use the reverse procedure for reassembly. When<br />

installing the foam polyurethane pre-cleaner, make sure<br />

the seam is installed to the outside to prevent gaps<br />

between the paper element and the pre-cleaner.<br />

POLYURETHANE-TYPE FILTER ELEMENT<br />

AIR CLEANER<br />

BODY<br />

FOAM<br />

ELEMENT<br />

1/2" (12.7 mm)<br />

FOAM<br />

WITH FLOCKED<br />

SCREEN<br />

ATTACHED<br />

3<br />

This type of air filter can be serviced when restricted with dust or dirt. Wash the filter or pre-cleaner in a liquid detergent<br />

and water solution until all the dirt is removed. Rinse in clear water to remove the detergent solution. Squeeze the<br />

element (do not twist) to remove the excess water. Wrap the element in a clean cloth and squeeze it (do not twist) until<br />

completely dry.<br />

Re-oil the element by applying engine oil and squeezing it vigorously to distribute the oil. Roll the element in a cloth and<br />

squeeze it (do not twist) to remove the excess oil.<br />

Clean the air cleaner housing and cover being careful not to allow dirt to fall into the carburetor or intake pipe.<br />

PAPER -TYPE FILTER ELEMENT<br />

Paper type air filter elements can only be serviced by replacement. Do not attempt to clean a paper filter element.<br />

6