MLD-S Tech-FB Library Description - Bosch Rexroth

MLD-S Tech-FB Library Description - Bosch Rexroth

MLD-S Tech-FB Library Description - Bosch Rexroth

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Rexroth</strong> <strong>MLD</strong>-S <strong>Tech</strong>-<strong>FB</strong> <strong>Library</strong> <strong>MLD</strong>-S <strong>Tech</strong>nology <strong>Library</strong> 1-43<br />

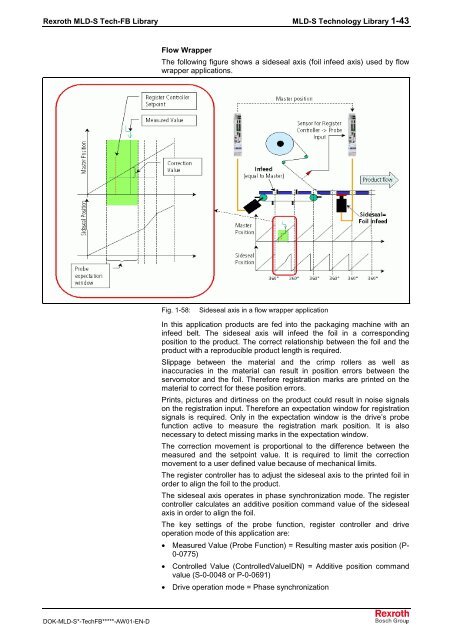

Flow Wrapper<br />

The following figure shows a sideseal axis (foil infeed axis) used by flow<br />

wrapper applications.<br />

Fig. 1-58:<br />

Sideseal axis in a flow wrapper application<br />

In this application products are fed into the packaging machine with an<br />

infeed belt. The sideseal axis will infeed the foil in a corresponding<br />

position to the product. The correct relationship between the foil and the<br />

product with a reproducible product length is required.<br />

Slippage between the material and the crimp rollers as well as<br />

inaccuracies in the material can result in position errors between the<br />

servomotor and the foil. Therefore registration marks are printed on the<br />

material to correct for these position errors.<br />

Prints, pictures and dirtiness on the product could result in noise signals<br />

on the registration input. Therefore an expectation window for registration<br />

signals is required. Only in the expectation window is the drive’s probe<br />

function active to measure the registration mark position. It is also<br />

necessary to detect missing marks in the expectation window.<br />

The correction movement is proportional to the difference between the<br />

measured and the setpoint value. It is required to limit the correction<br />

movement to a user defined value because of mechanical limits.<br />

The register controller has to adjust the sideseal axis to the printed foil in<br />

order to align the foil to the product.<br />

The sideseal axis operates in phase synchronization mode. The register<br />

controller calculates an additive position command value of the sideseal<br />

axis in order to align the foil.<br />

The key settings of the probe function, register controller and drive<br />

operation mode of this application are:<br />

• Measured Value (Probe Function) = Resulting master axis position (P-<br />

0-0775)<br />

• Controlled Value (ControlledValueIDN) = Additive position command<br />

value (S-0-0048 or P-0-0691)<br />

• Drive operation mode = Phase synchronization<br />

DOK-<strong>MLD</strong>-S*-<strong>Tech</strong><strong>FB</strong>*****-AW01-EN-D