2010 Kenworth T440/T470 Body Builder Manual

2010 Kenworth T440/T470 Body Builder Manual

2010 Kenworth T440/T470 Body Builder Manual

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Section 6<br />

<strong>Body</strong> Mounting<br />

Frame Sill<br />

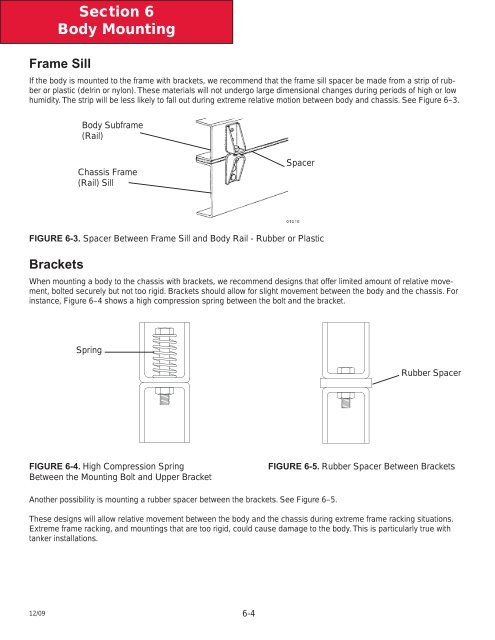

If the body is mounted to the frame with brackets, we recommend that the frame sill spacer be made from a strip of rubber<br />

or plastic (delrin or nylon). These materials will not undergo large dimensional changes during periods of high or low<br />

humidity. The strip will be less likely to fall out during extreme relative motion between body and chassis. See Figure 6–3.<br />

<strong>Body</strong> Subframe<br />

(Rail)<br />

Chassis Frame<br />

(Rail) Sill<br />

Spacer<br />

FIGURE 6-3. Spacer Between Frame Sill and <strong>Body</strong> Rail - Rubber or Plastic<br />

Brackets<br />

When mounting a body to the chassis with brackets, we recommend designs that offer limited amount of relative movement,<br />

bolted securely but not too rigid. Brackets should allow for slight movement between the body and the chassis. For<br />

instance, Figure 6–4 shows a high compression spring between the bolt and the bracket.<br />

Spring<br />

Rubber Spacer<br />

FIGURE 6-4. High Compression Spring<br />

Between the Mounting Bolt and Upper Bracket<br />

FIGURE 6-5. Rubber Spacer Between Brackets<br />

Another possibility is mounting a rubber spacer between the brackets. See Figure 6–5.<br />

These designs will allow relative movement between the body and the chassis during extreme frame racking situations.<br />

Extreme frame racking, and mountings that are too rigid, could cause damage to the body. This is particularly true with<br />

tanker installations.<br />

12/09<br />

6-4