Industrial seal self study guide - SKF.com

Industrial seal self study guide - SKF.com

Industrial seal self study guide - SKF.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Installation (cont.)<br />

8. Check <strong>seal</strong> direction. Make sure the new <strong>seal</strong> faces in the same<br />

direction as the original one. Generally, the lip faces the lubricant<br />

or fluid being retained.<br />

9. Use the correct installation tool. Press-fitting tools should have an<br />

outside diameter approximately .010” (.254mm) smaller than the<br />

bore size. For best results, the center of the tool should be open<br />

so that pressure is applied only at the outer edge.<br />

10. Pre-lubricate the <strong>seal</strong>ing element. Before installation, wipe the<br />

<strong>seal</strong>ing element and shaft with the lubricant being retained.<br />

Rubber O.D. <strong>seal</strong>s must be <strong>com</strong>pletely lubricated.<br />

11. Never hammer directly on the surface of the <strong>seal</strong>. Use proper<br />

driving force such as a soft face tool, arbor press or soft workpiece<br />

(wood). To avoid cocking the <strong>seal</strong>, apply force evenly around the<br />

outer edge.<br />

12. Position the <strong>seal</strong> properly in the housing and inspect for alignment<br />

and installation damage.<br />

Post-Installation Tips<br />

When painting, be sure to mask the <strong>seal</strong>. Avoid getting paint on the lip,<br />

or the shaft where the lip rides. Also, mask the vents so they will not<br />

be<strong>com</strong>e clogged.<br />

If paint is to be baked or the mechanism otherwise subjected to heat,<br />

the <strong>seal</strong>s should not be heated to temperatures higher than their<br />

materials can tolerate.<br />

In cleaning or testing, do not subject <strong>seal</strong>s to any fluids or pressures<br />

that could damage them. Check the Compound Selection Chart in<br />

the <strong>SKF</strong> Handbook of Seals when in doubt. Improper installation<br />

procedures will result in early <strong>seal</strong> failure. Three of the most <strong>com</strong>mon<br />

installation errors are detailed below.<br />

Common Installation Errors Damage from<br />

Shaft Burr<br />

Symptoms<br />

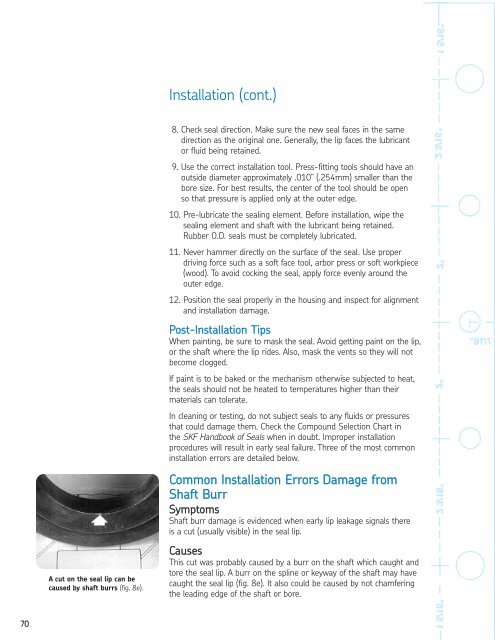

Shaft burr damage is evidenced when early lip leakage signals there<br />

is a cut (usually visible) in the <strong>seal</strong> lip.<br />

A cut on the <strong>seal</strong> lip can be<br />

caused by shaft burrs (fig. 8e).<br />

Causes<br />

This cut was probably caused by a burr on the shaft which caught and<br />

tore the <strong>seal</strong> lip. A burr on the spline or keyway of the shaft may have<br />

caught the <strong>seal</strong> lip (fig. 8e). It also could be caused by not chamfering<br />

the leading edge of the shaft or bore.<br />

70