Industrial seal self study guide - SKF.com

Industrial seal self study guide - SKF.com

Industrial seal self study guide - SKF.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Troubleshooting (cont...)<br />

Causes<br />

Such hammer damage can be caused by using a steel hammer on the<br />

<strong>seal</strong> housing during installation.<br />

B<br />

A<br />

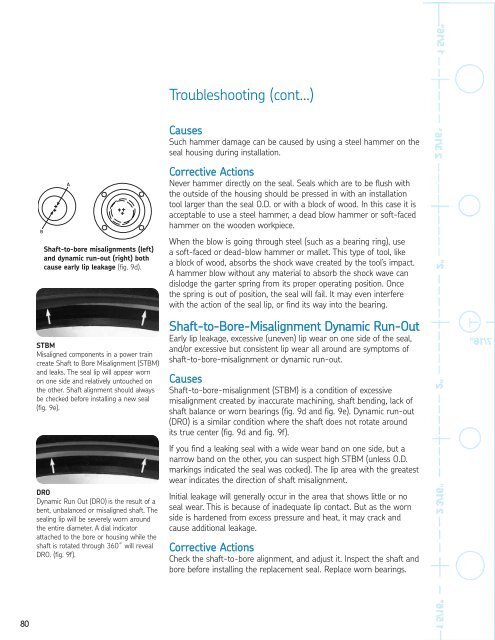

Shaft-to-bore misalignments (left)<br />

and dynamic run-out (right) both<br />

cause early lip leakage (fig. 9d).<br />

STBM<br />

Misaligned <strong>com</strong>ponents in a power train<br />

create Shaft to Bore Misalignment (STBM)<br />

and leaks. The <strong>seal</strong> lip will appear worn<br />

on one side and relatively untouched on<br />

the other. Shaft alignment should always<br />

be checked before installing a new <strong>seal</strong><br />

(fig. 9e).<br />

DRO<br />

Dynamic Run Out (DRO) is the result of a<br />

bent, unbalanced or misaligned shaft. The<br />

<strong>seal</strong>ing lip will be severely worn around<br />

the entire diameter. A dial indicator<br />

attached to the bore or housing while the<br />

shaft is rotated through 360˚ will reveal<br />

DRO. (fig. 9f).<br />

Corrective Actions<br />

Never hammer directly on the <strong>seal</strong>. Seals which are to be flush with<br />

the outside of the housing should be pressed in with an installation<br />

tool larger than the <strong>seal</strong> O.D. or with a block of wood. In this case it is<br />

acceptable to use a steel hammer, a dead blow hammer or soft-faced<br />

hammer on the wooden workpiece.<br />

When the blow is going through steel (such as a bearing ring), use<br />

a soft-faced or dead-blow hammer or mallet. This type of tool, like<br />

a block of wood, absorbs the shock wave created by the tool’s impact.<br />

A hammer blow without any material to absorb the shock wave can<br />

dislodge the garter spring from its proper operating position. Once<br />

the spring is out of position, the <strong>seal</strong> will fail. It may even interfere<br />

with the action of the <strong>seal</strong> lip, or find its way into the bearing.<br />

Shaft-to-Bore-Misalignment Dynamic Run-Out<br />

Early lip leakage, excessive (uneven) lip wear on one side of the <strong>seal</strong>,<br />

and/or excessive but consistent lip wear all around are symptoms of<br />

shaft-to-bore-misalignment or dynamic run-out.<br />

Causes<br />

Shaft-to-bore-misalignment (STBM) is a condition of excessive<br />

misalignment created by inaccurate machining, shaft bending, lack of<br />

shaft balance or worn bearings (fig. 9d and fig. 9e). Dynamic run-out<br />

(DRO) is a similar condition where the shaft does not rotate around<br />

its true center (fig. 9d and fig. 9f).<br />

If you find a leaking <strong>seal</strong> with a wide wear band on one side, but a<br />

narrow band on the other, you can suspect high STBM (unless O.D.<br />

markings indicated the <strong>seal</strong> was cocked). The lip area with the greatest<br />

wear indicates the direction of shaft misalignment.<br />

Initial leakage will generally occur in the area that shows little or no<br />

<strong>seal</strong> wear. This is because of inadequate lip contact. But as the worn<br />

side is hardened from excess pressure and heat, it may crack and<br />

cause additional leakage.<br />

Corrective Actions<br />

Check the shaft-to-bore alignment, and adjust it. Inspect the shaft and<br />

bore before installing the replacement <strong>seal</strong>. Replace worn bearings.<br />

80