- Page 1:

Engineering behavior of small-scale

- Page 6 and 7:

viLIST OF FIGURESFigure 1: Concept

- Page 8 and 9:

viiiFigure 62: Stress-settlement te

- Page 10 and 11:

xLIST OF TABLESTable 1: Stiffness m

- Page 12 and 13:

xiiLIST OF EQUATIONSEquation 1: Ult

- Page 14 and 15:

xivSymbol Description Unitsγ dry l

- Page 16 and 17:

1CHAPTER 1: INTRODUCTIONIndustry Pr

- Page 22 and 23:

7MAKECAVITYPLACESTONE ATBOTTOM OFCA

- Page 24 and 25:

9Normal Stress, kPaShear Stress. kP

- Page 26 and 27:

11pier element for a maximum of 25

- Page 28 and 29:

13savings provided by the system (A

- Page 30 and 31: 15The bearing capacity accredited t

- Page 32 and 33: 17Equation 12: Load resistance prov

- Page 34 and 35: 19Soil conditions at the site were

- Page 36 and 37: Settlement (mm)Settlement (mm)10202

- Page 38 and 39: 23Site soil conditions were describ

- Page 40 and 41: 25Article#ReferenceTable 2: Case st

- Page 42 and 43: 27Article#7ReferenceHughes andWithe

- Page 44 and 45: 29replaced with method of freezing

- Page 46 and 47: UNREINFORCED COLUMNNO COLUMNREINFOR

- Page 48 and 49: 33The load carrying capacity was fo

- Page 50 and 51: 35Case 5 - Bachus and Barksdale, 19

- Page 52 and 53: 37full depth of the consolidated la

- Page 54 and 55: 39CHAPTER 3: RESEARCH METHODOLOGYCr

- Page 56 and 57: 41itself was designed to be support

- Page 58 and 59: 43While it is obvious that the chan

- Page 60 and 61: 45To perform all the required testi

- Page 62 and 63: 47In the areas where access was lim

- Page 64 and 65: 49CBR from DCPThe California Bearin

- Page 66 and 67: 305 mm610 mm305 mm610 mm305 mm610 m

- Page 68 and 69: 53The process of using the Shelby t

- Page 70 and 71: 15881556144815591597154915271586158

- Page 72 and 73: 57Table 14: Top and bottom UC loess

- Page 74 and 75: 59Data Collection and SensorsHaving

- Page 76 and 77: 61Micro Epsilon displacement transd

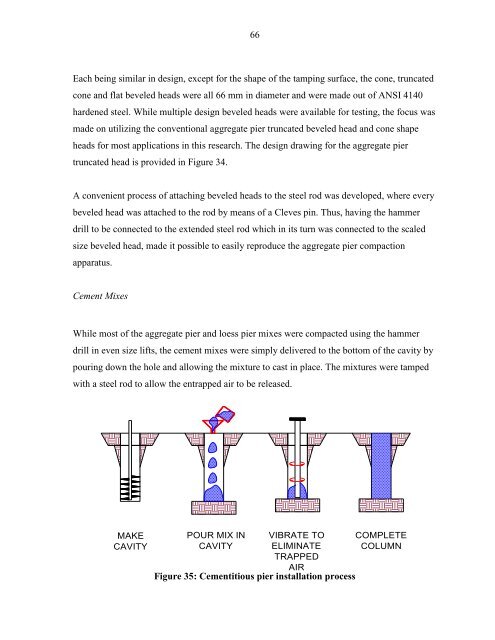

- Page 78 and 79: 63plate down the cavity through man

- Page 82 and 83: 67All, aggregate, cementitious and

- Page 84 and 85: 69DAQ Data CollectionWhile performi

- Page 86 and 87: 71space in the test bed (See Figure

- Page 88 and 89: 73(a)(b)(c)Figure 42: Test bed grou

- Page 90 and 91: 75CHAPTER 4: MATERIALSThe materials

- Page 92 and 93: 7710080LL = 31PI = 7Pass. #200 = 98

- Page 94 and 95: 79the second stage of testing. Mois

- Page 96 and 97: 81Knowing the gradation characteris

- Page 98 and 99: 83More importantly, the performed d

- Page 100 and 101: 85Figure 49: Cement type I compound

- Page 102 and 103: 87As the expansive and contractive

- Page 104 and 105: 89Figure 55: 19 mm polypropylene fi

- Page 106 and 107: 91CHAPTER 5: TEST RESULTS AND ANALY

- Page 108 and 109: 93Applied stress at top of pier (kP

- Page 110 and 111: 95Figure 60: Stress-settlement test

- Page 112 and 113: 97Figure 62: Stress-settlement test

- Page 114 and 115: 99Figure 64: Stress-settlement test

- Page 116 and 117: 101Figure 66: Stress-settlement tes

- Page 118 and 119: 103Figure 68: Stress-settlement tes

- Page 120 and 121: 105Settlement (mm)024681012Applied

- Page 122 and 123: 107to the maximum displacement of 1

- Page 124 and 125: 109The failure mechanism of other p

- Page 126 and 127: 1113000Measured Bearing Capacity (k

- Page 128 and 129: 113Applied stress at bottom of the

- Page 130 and 131:

115Figure 76: Stress-settlement tes

- Page 132 and 133:

117Figure 78: Stress-settlement tes

- Page 134 and 135:

119Settlement (mm)0246810Applied st

- Page 136 and 137:

121The group efficiency results wer

- Page 138 and 139:

123Pier typeAggregate PierUnit Cell

- Page 140 and 141:

125Figure 82: Stress-settlement tes

- Page 142 and 143:

127Figure 85: Stress-settlement tes

- Page 144 and 145:

129Figure 87: Stress-settlement tes

- Page 146 and 147:

131Applied stress at bottom of the

- Page 148 and 149:

133Table 33: Group efficiency compa

- Page 150 and 151:

135Having a limited amount of exper

- Page 152 and 153:

137Stiffness, kPa/mm600500400300200

- Page 154 and 155:

139In case with the piers consistin

- Page 156 and 157:

141Table 36: Stiffness ratio calcul

- Page 158 and 159:

143Some of the loess composition pi

- Page 160 and 161:

145Pier typeAggregatePierSingle Pie

- Page 162 and 163:

147Another observation was made, wh

- Page 164 and 165:

149As previously outlined, the stif

- Page 166 and 167:

151pier group efficiency values wer

- Page 168 and 169:

Stiffness Ratio1538Figure 91: Stiff

- Page 170 and 171:

155CHAPTER 7: SUMMARY AND CONCLUSIO

- Page 172 and 173:

157MaterialsLoess-CementVery intrig

- Page 174 and 175:

159Groups of PiersGroup of Aggregat

- Page 176 and 177:

161CHAPTER 8: FUTURE RESEARCHThe fu

- Page 178 and 179:

163Black, J.A., Sivakumar, V., Madh

- Page 180 and 181:

165Hanlong, L., An, D., and Yang, S

- Page 182 and 183:

167Randrup T.B., and Lichter, J.M.

- Page 184 and 185:

169Yeh, Y.K., and Mo, Y.L. (2005).

- Page 186 and 187:

171Group EfficiencyAggregate Pier G

- Page 188 and 189:

173Aggregate Pier305mm Wedge HeadDC

- Page 190 and 191:

175Loess + Fibers305mm Single PierD

- Page 192 and 193:

177Sand305mm Single PierDCPI, mm/bl

- Page 194 and 195:

179Aggregate Pier305mm Group of 4DC

- Page 196 and 197:

181C(I) + C(K)305mm Group of 4DCPI,

- Page 198 and 199:

183Aggregate Pier305mm Wedge HeadCB

- Page 200 and 201:

185Loess + Fibers305mm Single PierC

- Page 202 and 203:

187Sand305mm Single PierCBR, %0 2 4

- Page 204 and 205:

189Aggregate Pier305mm Group of 4CB

- Page 206 and 207:

191C(I) + C(K)305mm Group of 4CBR,