Biomass Resource Assessment Part I - Gainesville Regional Utilities

Biomass Resource Assessment Part I - Gainesville Regional Utilities

Biomass Resource Assessment Part I - Gainesville Regional Utilities

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

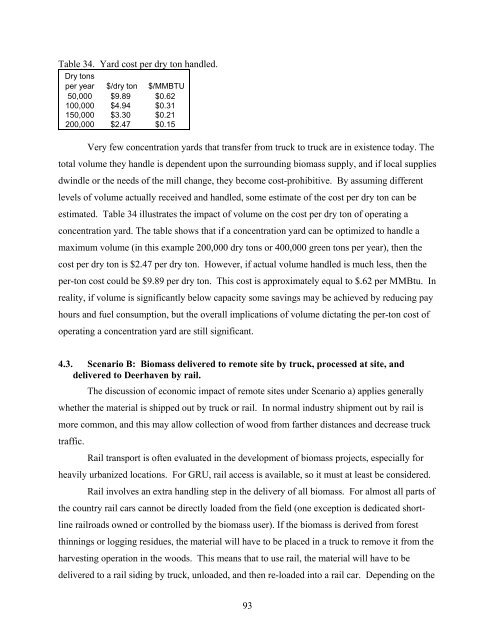

Table 34. Yard cost per dry ton handled.Dry tonsper year $/dry ton $/MMBTU50,000 $9.89 $0.62100,000 $4.94 $0.31150,000 $3.30 $0.21200,000 $2.47 $0.15Very few concentration yards that transfer from truck to truck are in existence today. Thetotal volume they handle is dependent upon the surrounding biomass supply, and if local suppliesdwindle or the needs of the mill change, they become cost-prohibitive. By assuming differentlevels of volume actually received and handled, some estimate of the cost per dry ton can beestimated. Table 34 illustrates the impact of volume on the cost per dry ton of operating aconcentration yard. The table shows that if a concentration yard can be optimized to handle amaximum volume (in this example 200,000 dry tons or 400,000 green tons per year), then thecost per dry ton is $2.47 per dry ton. However, if actual volume handled is much less, then theper-ton cost could be $9.89 per dry ton. This cost is approximately equal to $.62 per MMBtu. Inreality, if volume is significantly below capacity some savings may be achieved by reducing payhours and fuel consumption, but the overall implications of volume dictating the per-ton cost ofoperating a concentration yard are still significant.4.3. Scenario B: <strong>Biomass</strong> delivered to remote site by truck, processed at site, anddelivered to Deerhaven by rail.The discussion of economic impact of remote sites under Scenario a) applies generallywhether the material is shipped out by truck or rail. In normal industry shipment out by rail ismore common, and this may allow collection of wood from farther distances and decrease trucktraffic.Rail transport is often evaluated in the development of biomass projects, especially forheavily urbanized locations. For GRU, rail access is available, so it must at least be considered.Rail involves an extra handling step in the delivery of all biomass. For almost all parts ofthe country rail cars cannot be directly loaded from the field (one exception is dedicated shortlinerailroads owned or controlled by the biomass user). If the biomass is derived from forestthinnings or logging residues, the material will have to be placed in a truck to remove it from theharvesting operation in the woods. This means that to use rail, the material will have to bedelivered to a rail siding by truck, unloaded, and then re-loaded into a rail car. Depending on the93