Safety Organization/North Central Railway - eLocoS

Safety Organization/North Central Railway - eLocoS

Safety Organization/North Central Railway - eLocoS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

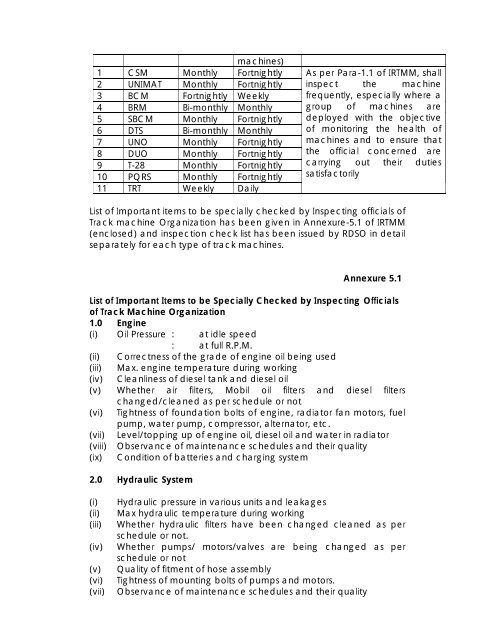

machines)1 CSM Monthly Fortnightly As per Para-1.1 of IRTMM, shall2 UNIMAT Monthly Fortnightly inspect the machine3 BCM Fortnightly Weekly frequently, especially where a4 BRM Bi-monthly Monthly group of machines are5 SBCM Monthly Fortnightly deployed with the objective6 DTS Bi-monthly Monthly of monitoring the health of7 UNO Monthly Fortnightly machines and to ensure that8 DUO Monthly Fortnightly the official concerned are9 T-28 Monthly Fortnightly carrying out their duties10 PQRS Monthly Fortnightly satisfactorily11 TRT Weekly DailyList of Important items to be specially checked by Inspecting officials ofTrack machine <strong>Organization</strong> has been given in Annexure-5.1 of IRTMM(enclosed) and inspection check list has been issued by RDSO in detailseparately for each type of track machines.Annexure 5.1List of Important Items to be Specially Checked by Inspecting Officialsof Track Machine <strong>Organization</strong>1.0 Engine(i) Oil Pressure : at idle speed: at full R.P.M.(ii) Correctness of the grade of engine oil being used(iii) Max. engine temperature during working(iv) Cleanliness of diesel tank and diesel oil(v) Whether air filters, Mobil oil filters and diesel filterschanged/cleaned as per schedule or not(vi) Tightness of foundation bolts of engine, radiator fan motors, fuelpump, water pump, compressor, alternator, etc.(vii) Level/topping up of engine oil, diesel oil and water in radiator(viii) Observance of maintenance schedules and their quality(ix) Condition of batteries and charging system2.0 Hydraulic System(i)(ii)(iii)(iv)(v)(vi)(vii)Hydraulic pressure in various units and leakagesMax hydraulic temperature during workingWhether hydraulic filters have been changed cleaned as perschedule or not.Whether pumps/ motors/valves are being changed as perschedule or notQuality of fitment of hose assemblyTightness of mounting bolts of pumps and motors.Observance of maintenance schedules and their quality