Safety Organization/North Central Railway - eLocoS

Safety Organization/North Central Railway - eLocoS

Safety Organization/North Central Railway - eLocoS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

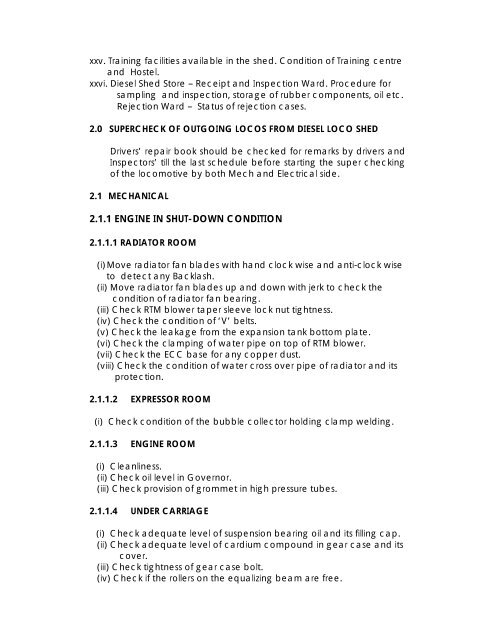

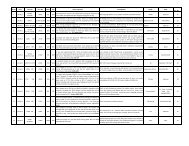

xxv. Training facilities available in the shed. Condition of Training centreand Hostel.xxvi. Diesel Shed Store – Receipt and Inspection Ward. Procedure forsampling and inspection, storage of rubber components, oil etc.Rejection Ward – Status of rejection cases.2.0 SUPERCHECK OF OUTGOING LOCOS FROM DIESEL LOCO SHEDDrivers’ repair book should be checked for remarks by drivers andInspectors’ till the last schedule before starting the super checkingof the locomotive by both Mech and Electrical side.2.1 MECHANICAL2.1.1 ENGINE IN SHUT-DOWN CONDITION2.1.1.1 RADIATOR ROOM(i) Move radiator fan blades with hand clock wise and anti-clock wiseto detect any Backlash.(ii) Move radiator fan blades up and down with jerk to check thecondition of radiator fan bearing.(iii) Check RTM blower taper sleeve lock nut tightness.(iv) Check the condition of ‘V’ belts.(v) Check the leakage from the expansion tank bottom plate.(vi) Check the clamping of water pipe on top of RTM blower.(vii) Check the ECC base for any copper dust.(viii) Check the condition of water cross over pipe of radiator and itsprotection.2.1.1.2 EXPRESSOR ROOM(i) Check condition of the bubble collector holding clamp welding.2.1.1.3 ENGINE ROOM(i) Cleanliness.(ii) Check oil level in Governor.(iii) Check provision of grommet in high pressure tubes.2.1.1.4 UNDER CARRIAGE(i) Check adequate level of suspension bearing oil and its filling cap.(ii) Check adequate level of cardium compound in gear case and itscover.(iii) Check tightness of gear case bolt.(iv) Check if the rollers on the equalizing beam are free.