Safety Organization/North Central Railway - eLocoS

Safety Organization/North Central Railway - eLocoS

Safety Organization/North Central Railway - eLocoS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

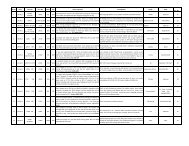

(vii) WJR timing for “N” & “R”(viii) A ward on point motor corresponds with the KLR.(ix) Cleanliness of carbon brush & availability of chamois leather.2.3 TRACK CIRCUIT(i) Track circuit parameters are within limit.(ii) Relays are not overdue for overhauling.(iii) Track circuit history card are maintained every six months.(iv) Track circuit batteries are positively wired in circuit.(v) Track circuit in flood prone areas and improvement needed like axlecounter in parallel.(vi) Testing of GJ/IBJ and replacement of IBJ/William stretcher/GaugePlate/Tounge attachment is done as per schedule & procedure followedduring replacement.(vii) OHE bands are available on FP/SEJ & track crossing is insulated.(viii) Double track lead wires are provided.(ix) Channel pins are replaced every six months and track lead every year.(x) AFTC receiver voltage is within prescribed limits(xi) AFTC bonds are provided and properly connected with Rails(xii) All track connections are properly made.(xiii) No spare/released rail is lying parallel to track(xiv) OHE masts are connected as per manual provisions(xv) AFTC S/Alfa/Tx/Rx Bonds are replaced every 2 to 3 years or on conditionbasis and as per periodicity defined from time to time.(xvi) Separate terminals for measurement of voltages are provided for UM 71TCs and measurement is not from back of base pins.2.4 SIGNAL(i) LED is provided with current regulators with proper setting forConventional or LED ECR as per ECR provided(ii) HMU functions is checked regularly as per schedule where provided.(iii) Cases of repeated LED and CRU fusing/failure of a signal or particularmake.(iv) Signal is secured properly and earthed.(v) Rodents entry and ingress of moisture and rain water is properly plugged.(vi) SPDs are provided across each aspect.2.5 LEVER LOCK & CIRCUIT CONTROLLER(i)(ii)(iii)Proper adjustment of bands & make in proper position.Serrations are holding bands and nut/split pin are intact.Lock is effective and releases at the required position.2.6 POWER EQUIPMENT, BATTERIES & FUSES(i)(ii)(iii)(iv)(v)(vi)Battery conditions and year of installation, plan for replacement.Battery maintenance SG & voltage.Load capacity.Redundant fuses are removed.Programme switch contacts are made parallel,Parallel fuses in relays & other circuits with indication arrangement and