salisbury

salisbury

salisbury

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

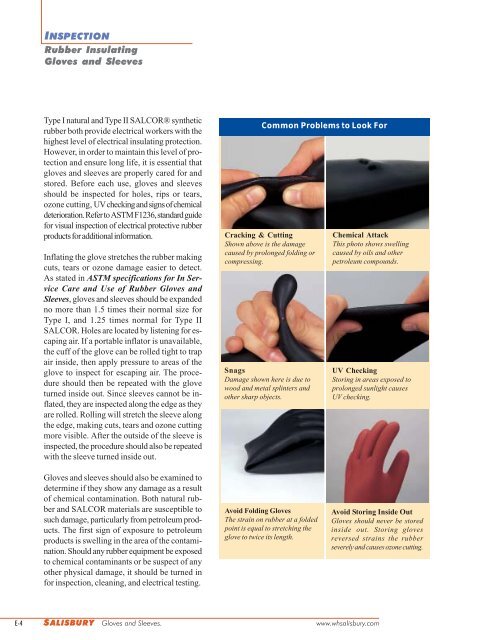

INSPECTIONRubber InsulatingGloves and SleevesType I natural and Type II SALCOR® syntheticrubber both provide electrical workers with thehighest level of electrical insulating protection.However, in order to maintain this level of protectionand ensure long life, it is essential thatgloves and sleeves are properly cared for andstored. Before each use, gloves and sleevesshould be inspected for holes, rips or tears,ozone cutting, UV checking and signs of chemicaldeterioration. Refer to ASTM F1236, standard guidefor visual inspection of electrical protective rubberproducts for additional information.Inflating the glove stretches the rubber makingcuts, tears or ozone damage easier to detect.As stated in ASTM specifications for In ServiceCare and Use of Rubber Gloves andSleeves, gloves and sleeves should be expandedno more than 1.5 times their normal size forType I, and 1.25 times normal for Type IISALCOR. Holes are located by listening for escapingair. If a portable inflator is unavailable,the cuff of the glove can be rolled tight to trapair inside, then apply pressure to areas of theglove to inspect for escaping air. The procedureshould then be repeated with the gloveturned inside out. Since sleeves cannot be inflated,they are inspected along the edge as theyare rolled. Rolling will stretch the sleeve alongthe edge, making cuts, tears and ozone cuttingmore visible. After the outside of the sleeve isinspected, the procedure should also be repeatedwith the sleeve turned inside out.Common Problems to Look ForCracking & CuttingShown above is the damagecaused by prolonged folding orcompressing.SnagsDamage shown here is due towood and metal splinters andother sharp objects.Chemical AttackThis photo shows swellingcaused by oils and otherpetroleum compounds.UV CheckingStoring in areas exposed toprolonged sunlight causesUV checking.Gloves and sleeves should also be examined todetermine if they show any damage as a resultof chemical contamination. Both natural rubberand SALCOR materials are susceptible tosuch damage, particularly from petroleum products.The first sign of exposure to petroleumproducts is swelling in the area of the contamination.Should any rubber equipment be exposedto chemical contaminants or be suspect of anyother physical damage, it should be turned infor inspection, cleaning, and electrical testing.Avoid Folding GlovesThe strain on rubber at a foldedpoint is equal to stretching theglove to twice its length.Avoid Storing Inside OutGloves should never be storedinside out. Storing glovesreversed strains the rubberseverely and causes ozone cutting.E-4SALISBURY Gloves and Sleeves. www.wh<strong>salisbury</strong>.com