- Page 1 and 2:

Naval Education and Training Comman

- Page 3 and 4:

MACHINERY REPAIRMAN NAVEDTRA 12204-

- Page 6 and 7:

PREFACE This Training Manual (TRAMA

- Page 8 and 9:

CONTENTS CHAPTER PAGE 1. 2. 3. 4. 5

- Page 10 and 11:

Another job description found in pr

- Page 12 and 13:

1-2, and 1-3 show some of the commo

- Page 14 and 15:

You must know the location of tools

- Page 16 and 17:

The correct way to measure an insid

- Page 18 and 19:

appropriate sides of the jaws on th

- Page 20 and 21:

Dial Bore Gauge The dial bore gauge

- Page 22 and 23:

Gear Tooth Vernier Use a gear tooth

- Page 24 and 25:

Surface Gauge A surface gauge (fig.

- Page 26 and 27:

Figure 1-20.—Center gauge. angle

- Page 28 and 29:

accuracy. They generally come in ma

- Page 30 and 31:

MICROMETERS is essentially the same

- Page 32 and 33:

meanings of these terms and the imp

- Page 34 and 35:

number is shown for roughness heigh

- Page 36 and 37:

Figure 2-7.—Master roughness scal

- Page 38 and 39:

Figure 2-11.—Checking surface fin

- Page 40 and 41:

Figure 2-17.—Laying out a 45-degr

- Page 42 and 43:

Figure 2-24.—Setting and using a

- Page 44 and 45:

Figure 2-29.—Bisecting an angle.

- Page 46 and 47:

prick-punch “witness marks” aro

- Page 48 and 49:

Figure 2-35.—Filing. The crosshat

- Page 50 and 51:

keyway broach requires a bushing th

- Page 52 and 53:

The steps involved in repairing a d

- Page 54 and 55:

SETTING UP OXYACETYLENE EQUIPMENT T

- Page 56 and 57:

GREASE IN THE PRESENCE OF OXYGEN UN

- Page 58 and 59:

Strength metal into thin sheets. Le

- Page 60 and 61:

and forming into plates, billets, b

- Page 62 and 63:

Each of the aluminum alloys has pro

- Page 64 and 65:

with an average carbon content of 1

- Page 66 and 67:

The manufacturer is required to mak

- Page 68 and 69:

with that of known specimens. Many

- Page 70 and 71:

Gray cast iron produces a spark str

- Page 72 and 73:

Table 3-4.—Major Groups of Plasti

- Page 74 and 75:

Lathe Operations Lathe operations a

- Page 76 and 77:

mechanism is also attached to the s

- Page 78 and 79:

Band Selection and Installation The

- Page 80 and 81:

File Bands A file band consists of

- Page 82 and 83:

This prevents sagging of the file b

- Page 84 and 85:

Figure 4-16.—Butt welder-grinder

- Page 86 and 87:

paragraphs contain the procedures f

- Page 88 and 89:

Figure 4-22.—Disk-cutting attachm

- Page 90 and 91:

Figure 4-26.—Sensitive drill pres

- Page 92 and 93:

shops are the Morse taper shank, sh

- Page 94 and 95:

Figure 4-30.—Common types of clam

- Page 96 and 97:

Figure 4-34.—Two types of counter

- Page 98 and 99:

andomly follow the straight sides a

- Page 101 and 102:

CHAPTER 5 OFFHAND GRINDING OF TOOLS

- Page 103 and 104:

Figure 5-4.—Standard marking syst

- Page 105 and 106:

DIAMOND WHEELS Diamond grinding whe

- Page 107 and 108:

WHEEL CARE AND STORAGE It’s easy

- Page 109 and 110:

allows cutting speeds approximately

- Page 111 and 112:

Figure 5-13.—Surface finish vs no

- Page 113 and 114:

Figure 5-17.—Boring bars for carb

- Page 115 and 116:

Figure 5-19.—Chip breakers. a rad

- Page 117 and 118:

Internal-threading tool: The intern

- Page 119 and 120:

Downcutting tool: You may grind and

- Page 121 and 122:

Figure 5-32.—Grinding drill lip c

- Page 123:

Figure 5-37.—Grinding a twist dri

- Page 126 and 127: ways in alignment with the headstoc

- Page 128 and 129: Figure 6-4 shows this plate for the

- Page 130 and 131: Before you insert a center or tooli

- Page 132 and 133: FEED ROD The feed rod transmits pow

- Page 134 and 135: lower lever has eight positions, ea

- Page 136 and 137: Figure 6-14.—Quick-change toolpos

- Page 138 and 139: Figure 6-21.—Three-jaw universal

- Page 140 and 141: Figure 6-26.—Cutaway showing the

- Page 142 and 143: Figure 6-32.—Thread dial indicato

- Page 144 and 145: TRACING ATTACHMENTS A tracing attac

- Page 146 and 147: 2. Place the level across the bed a

- Page 148 and 149: Figure 6-41.—Aligning lathe cente

- Page 150 and 151: Figure 6-45.—Boring center hole.

- Page 152 and 153: ends of the mandrel when you press

- Page 154 and 155: Figure 6-52.—Centering work with

- Page 156 and 157: Figure 6-56.—Work mounted on a ca

- Page 158 and 159: FEED is the amount the tool advance

- Page 160 and 161: Rough Turning Figure 6-62.—Rough

- Page 162 and 163: Square, round, and “V” grooves

- Page 164 and 165: Figure 6-69.—Knurled impressions.

- Page 166 and 167: machined surfaces that could become

- Page 168 and 169: produced by the same amount of seto

- Page 170 and 171: cross-feed screw and the cross-slid

- Page 172 and 173: When special threads are required b

- Page 174 and 175: Figure 6-83.—Acme thread and form

- Page 178 and 179: The wire size you should use to mea

- Page 180 and 181: Using the Thread-Cutting Stop Becau

- Page 182 and 183: Figure 6-96.—Finishing the end of

- Page 184 and 185: shown in figure 6-101. Two slots ar

- Page 186 and 187: Figure 7-1.—Universal milling mac

- Page 188 and 189: A. Spindle G. Spindle speed selecto

- Page 190 and 191: with a split clamp to the overarm a

- Page 192 and 193: to the table of the milling machine

- Page 194 and 195: that most index heads have a 40 to

- Page 196 and 197: Rapid indexing is used when a large

- Page 198 and 199: or one complete turn plus 36 holes

- Page 200 and 201: allows you to index divisions from

- Page 202 and 203: from the one in which the pin is in

- Page 204 and 205: Figure 7-24.—Side milling cutter.

- Page 206 and 207: A. B. C. D. E. Figure 7-32.—Doubl

- Page 208 and 209: Figure 7-36.—Inserted tooth face

- Page 210 and 211: Figure 7-43.—Sprocket wheel cutte

- Page 212 and 213: Figure 7-48.—Stub arbor. or on th

- Page 214 and 215: Figure 7-54.—Spring collet chuck

- Page 216 and 217: Figure 7-56.—Face milling. FACE M

- Page 218 and 219: 11. 12. 13. 14. 15. 16. 17. 18. 19.

- Page 220 and 221: A. Lock screw for dog D. End mill B

- Page 222 and 223: 8. 9. 10. 11. 12. 13. 14. 15. 16. 1

- Page 224 and 225: 11. 12. 13. 14. 15. 16. 17. 18. 19.

- Page 226 and 227:

Figure 7-71.—Visual alignment of

- Page 228 and 229:

machine table. You will hold the cu

- Page 230 and 231:

Figure 7-77.—Boring with a fly cu

- Page 232 and 233:

Figure 7-79.—Vertical milling att

- Page 234 and 235:

Table 7-2.—Surface Cutting Speeds

- Page 236 and 237:

Table 7-4 shows recommended chip lo

- Page 238 and 239:

Figure 8-2.—A 36-inch vertical tu

- Page 240 and 241:

28.194 Figure 8-3.—Refacing a val

- Page 242 and 243:

HORIZONTAL BORING MILL The horizont

- Page 244 and 245:

7. After you have tightened the mou

- Page 246 and 247:

The table can be power driven to pr

- Page 249 and 250:

CHAPTER 9 SHAPERS, PLANERS, AND ENG

- Page 251 and 252:

Figure 9-3.—Swiveled and tilted t

- Page 253 and 254:

extent in planer and shaper work To

- Page 255 and 256:

the cutting speeds and related mach

- Page 257 and 258:

Figure 9-10.—Internal keyway: A.

- Page 259 and 260:

7. 8. 9. 10. 11. 12. 13. 14. Replac

- Page 261 and 262:

or housing attached on one side of

- Page 263 and 264:

Figure 9-18.—Engraving machine. F

- Page 265 and 266:

CUTTER SPEEDS The speeds listed in

- Page 267 and 268:

can readily see it after grinding t

- Page 269 and 270:

Figure 9-29.—Using an indexing at

- Page 271:

Any further movement of the work wi

- Page 274 and 275:

Figure 10-1.—Grain depth of cut;

- Page 276 and 277:

To select the proper work speed, ta

- Page 278 and 279:

Figure 10-8.—Magnetic chuck used

- Page 280 and 281:

can do on a surface grinder. Use th

- Page 282 and 283:

for straight cylindrical grinding o

- Page 284 and 285:

Figure 10-15.—Typical tooth rest

- Page 286 and 287:

of the work. Raise or lower the whe

- Page 288 and 289:

Figure 10-23.—Staggered-tooth sid

- Page 290 and 291:

Figure 10-28.—Grinding the periph

- Page 292 and 293:

Once the teeth are uniform, they sh

- Page 294 and 295:

After you have honed out the inaccu

- Page 296 and 297:

MACHINES With the rapid development

- Page 298 and 299:

Figure 11-3.—Slant bed for CNC la

- Page 300 and 301:

Figure 11-6.—A typical CNC contro

- Page 302 and 303:

Figure 11-8.—Continuous-path angl

- Page 304 and 305:

CHAPTER 12 METAL BUILDUP CHAPTER LE

- Page 306 and 307:

Figure 12-1.—Typical installation

- Page 308 and 309:

Figure 12-5.—A typical sandblaste

- Page 310 and 311:

Clean, dry air is essential for pro

- Page 312 and 313:

It can reduce the amount of masking

- Page 314 and 315:

quality assurance function of the p

- Page 316 and 317:

pass-fail. In our educational syste

- Page 318 and 319:

straighten a shaft, however, always

- Page 320 and 321:

Figure 13-4.—Lapping tools. has t

- Page 322 and 323:

pipe in which the valve is installe

- Page 324 and 325:

Figure 13-10.—Constant-pressure g

- Page 326 and 327:

When you install the control valve

- Page 328 and 329:

casing wearing rings, impeller wear

- Page 330 and 331:

Figure 13-17.—Removing a broken b

- Page 332 and 333:

Figure 13-23.—Metal disintegrator

- Page 334 and 335:

Figure 13-25.—Portable boring bar

- Page 336 and 337:

Figure 14-1.—Cutting specially sh

- Page 338 and 339:

For example, use the following proc

- Page 340 and 341:

at an angle to each other, as long

- Page 342 and 343:

Figure 14-6.—Development of evenl

- Page 344 and 345:

Table 14-1.—"K" Factor Table Tabl

- Page 346 and 347:

Figure 14-11.—Standard universal

- Page 348 and 349:

6. Find the NPD. 7. Find the 8. Fin

- Page 350 and 351:

FA - Face angle OD - Outside diamet

- Page 352 and 353:

7. Pitch diameter (PD)—This is th

- Page 354 and 355:

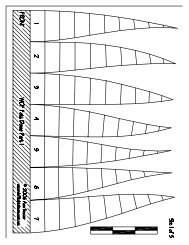

SELECTING A BEVEL GEAR CUTTER To cu

- Page 356 and 357:

Figure 14-20.—Profiling a bevel g

- Page 358 and 359:

. Use the following formulas to sol

- Page 360 and 361:

Figure 14-25.—Milling machine set

- Page 362 and 363:

9. Diametral pitch (DP) METHOD OF M

- Page 364 and 365:

explains the classes and the manufa

- Page 366 and 367:

GRAINS (irregularly shaped crystals

- Page 368 and 369:

Figure 15-2.—Microscopic structur

- Page 370 and 371:

Figure 15-5.—Typical structure of

- Page 372 and 373:

Figure 15-8.—Grid for heat-treati

- Page 374 and 375:

Table 15-3.—Average Cooling Rates

- Page 376 and 377:

cases. A wide variety of quenching

- Page 378 and 379:

These various temperature arrests o

- Page 380 and 381:

known as pearlite, and the A1 tempe

- Page 382 and 383:

quickly cooled to and held at a som

- Page 384 and 385:

Available information indicates tha

- Page 386 and 387:

slowly from the tempering temperatu

- Page 388 and 389:

Table 15-4.—Heat-Treating Tempera

- Page 390 and 391:

Figure 15-20.—Design of a cam. A.

- Page 392 and 393:

In carburized steel, spalling is ca

- Page 394 and 395:

used to make positive identificatio

- Page 396 and 397:

HONING—Finishing machine operatio

- Page 398 and 399:

Table AII-2.—Decimal Equivalents

- Page 400 and 401:

Table AII-4.—Formulas for Dimensi

- Page 402 and 403:

Table AII-5.—Number, Letter and F

- Page 404 and 405:

Table AII-7.—Screw Thread and Tap

- Page 406 and 407:

Table AII-9.—3-Wire Method of Mea

- Page 408 and 409:

Table AII-11.—Circles Circumferen

- Page 410 and 411:

Table AII-13.—Taper Per Foot and

- Page 412 and 413:

p 1 I vi 2 P F \ = = a AII-16

- Page 414 and 415:

Table AII-16.—Drill Sizes for Tap

- Page 416 and 417:

Having Circular pitch Circular pitc

- Page 419 and 420:

APPENDIX IV DERIVATION OF FORMULAS

- Page 421:

(1) NT is the connecting link betwe

- Page 424 and 425:

Walker, John R., Machining Fundamen

- Page 427 and 428:

A Adjustable gauges, 1-7 adjustable

- Page 429 and 430:

Engine lathes, 6-1 attachments and

- Page 431 and 432:

Layout methods, 2-8 M forming angul

- Page 433 and 434:

Stub tooth gears, 14-27 American st