You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

8.<br />

9.<br />

10.<br />

11.<br />

12.<br />

13.<br />

14.<br />

15.<br />

16.<br />

17.<br />

18.<br />

19.<br />

20.<br />

21.<br />

22.<br />

23.<br />

24.<br />

25.<br />

closely as possible to the cutter. Make sure<br />

that the work and the vise will clear all parts<br />

of the machine.<br />

Install the arbor nut and tighten it finger tight<br />

only.<br />

Position the overarm and mount the arbor<br />

support.<br />

After supporting the arbor, tighten the arbor<br />

nut with a wrench.<br />

Set the spindle directional control lever to<br />

give the required direction of cutter rotation.<br />

Determine the required speed and feed, and<br />

set the spindle speed and feed controls.<br />

Set the feed trip dogs for the desired length of<br />

cut and center the work under the cutter.<br />

Lock the saddle.<br />

Engage the spindle clutch and pick up the cut.<br />

Pick up the surface of the work by holding a<br />

long strip of paper between the rotating cutter<br />

and the work; very slowly move the work<br />

toward the cutter until the paper strip is<br />

pulled between the cutter and the work.<br />

Keep your fingers away from the cutter. A<br />

rotating milling cutter is very dangerous.<br />

Move the work longitudinally away from the<br />

cutter and set the vertical feed graduated<br />

collar at ZERO.<br />

Compute the depth of the roughing cut and<br />

raise the knee this distance.<br />

Lock the knee, and direct the coolant flow on<br />

the work and on the outgoing side of the<br />

cutter.<br />

Position the cutter to within 1/16 inch of the<br />

work, using hand table feed.<br />

Engage the power feed.<br />

After completing the cut, stop the spindle.<br />

Return the work to its starting point on the<br />

other side of the cutter.<br />

Raise the table the distance required for the<br />

finish cut.<br />

Set the finishing speed and feed, and take the<br />

finish cut.<br />

7-31<br />

26. When you have completed the operation,<br />

stop the spindle and return the work to the<br />

opposite side of the cutter.<br />

27. Deburr the work and remove it from the vise.<br />

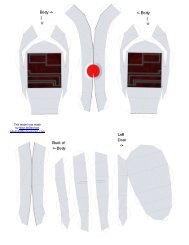

To machine the second side, place the work in the<br />

vise as shown in figure 7-55, view B. Rough and<br />

finish machine side 2, using the same procedures that<br />

you used for side 1. When you have completed side 2,<br />

deburr the surface and remove the work from the vise.<br />

Place the work in the vise, as shown in figure<br />

7-55, view C, with side 3 up. Then, rough machine<br />

side 3. Finish machine side 3 for a short distance,<br />

disengage the spindle and feed, and return the work to<br />

the starting point, clear of the cutter. Now you can<br />

safely measure the distance between sides 2 and 3. If<br />

this distance is correct, you can continue the cut with<br />

the same setting. If it is not, adjust the depth of cut as<br />

necessary. If the trial finishing cut is not deep<br />

enough, raise the work slightly and take another trial<br />

cut. If the trial cut is too deep, you will have to<br />

remove the backlash from the vertical feed before<br />

taking the new depth of cut. Use the following<br />

procedure to remove the backlash:<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

Lower the knee well past the original depth<br />

of the roughing cut.<br />

Raise the knee the correct distance for the<br />

finishing cut.<br />

Engage the feed and complete your cut.<br />

Stop the spindle.<br />

Return the work to the starting point on the<br />

other side of the cutter.<br />

6. Deburr the work.<br />

7. Remove the work from the vise.<br />

Place side 4 in the vise, as shown in figure 7-55,<br />

view D, and machine the side, using the same<br />

procedure as for side 3. When you have completed<br />

side 4, remove the work from the vise and check it for<br />

accuracy.<br />

This completes the machining of the four sides of<br />

the block. If the block is not too long, you can rough<br />

and finish mill the ends to size in the same manner in<br />

which you milled the sides. Do this by placing the<br />

block on end in the vise. You also may use face<br />

milling to machine the ends.