- Page 1: User’sManualModel DYVortex Flowme

- Page 4 and 5: CONTENTS10. MAINTENANCE ...........

- Page 6 and 7: INTRODUCTIONINTRODUCTIONThe DY seri

- Page 8 and 9: INTRODUCTION■ Using the Vortex Fl

- Page 10 and 11: INTRODUCTIONSKPLCZSLOLTHLVBGESTROMi

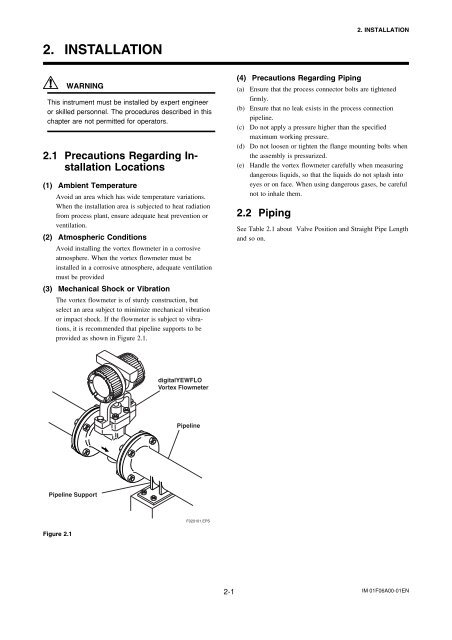

- Page 14 and 15: 2. INSTALLATION●Piping supportTyp

- Page 16 and 17: 2. INSTALLATION2.3 Precautions Rega

- Page 18 and 19: 2. INSTALLATION2.6 Installing the V

- Page 20 and 21: 2. INSTALLATIONTable 2.3(b)Installa

- Page 22 and 23: 3. WIRINGIMPORTANTFor pulse output

- Page 24 and 25: 3. WIRING3.4 Wiring Cables and Wire

- Page 26 and 27: 3. WIRING3.6.2 For Vortex Flow Conv

- Page 28 and 29: 4. BASIC OPERATING PROCEDURES4. BAS

- Page 30 and 31: 4. BASIC OPERATING PROCEDURES4.3 Di

- Page 32 and 33: 4. BASIC OPERATING PROCEDURES4.3.2

- Page 34 and 35: 4. BASIC OPERATING PROCEDURES4.4.2

- Page 36 and 37: 5. PARAMETER SETUP5. PARAMETER SETU

- Page 38 and 39: (3) Item C : BASIC SETUP5. PARAMETE

- Page 40 and 41: 5. PARAMETER SETUP(5) Item E : Dete

- Page 42 and 43: 5. PARAMETER SETUP(7) Item H : Adju

- Page 44 and 45: 5. PARAMETER SETUP5.4 Parameter Des

- Page 46 and 47: 5. PARAMETER SETUP(3) Item C : BASI

- Page 48 and 49: 5. PARAMETER SETUP(5) Item E (METER

- Page 50 and 51: 5. PARAMETER SETUP(7) Item H (ADJUS

- Page 52 and 53: 5. PARAMETER SETUP5.5 Error Code Li

- Page 54 and 55: 6. Operation for the BRAIN Terminal

- Page 56 and 57: 6. Operation for the BRAIN Terminal

- Page 58 and 59: 7. OPERATION VIA HART CONFIGURATION

- Page 60 and 61: 7. OPERATION VIA HART CONFIGURATION

- Page 62 and 63:

7. OPERATION VIA HART CONFIGURATION

- Page 64 and 65:

7. OPERATION VIA HART CONFIGURATION

- Page 66 and 67:

7. OPERATION VIA HART CONFIGURATION

- Page 68 and 69:

8. OPERATION VIA HART CONFIGURATION

- Page 70 and 71:

8. OPERATION VIA HART CONFIGURATION

- Page 72 and 73:

8. OPERATION VIA HART CONFIGURATION

- Page 74 and 75:

8. OPERATION VIA HART CONFIGURATION

- Page 76 and 77:

8. OPERATION VIA HART CONFIGURATION

- Page 78 and 79:

8. OPERATION VIA HART CONFIGURATION

- Page 80 and 81:

8. OPERATION VIA HART CONFIGURATION

- Page 82 and 83:

8. OPERATION VIA HART CONFIGURATION

- Page 84 and 85:

8. OPERATION VIA HART CONFIGURATION

- Page 86 and 87:

8. OPERATION VIA HART CONFIGURATION

- Page 88 and 89:

8. OPERATION VIA HART CONFIGURATION

- Page 90 and 91:

9. OPERATION9. OPERATIONAfter you h

- Page 92 and 93:

9. OPERATIONFor more details regard

- Page 94 and 95:

10. MAINTENANCE10. MAINTENANCECAUTI

- Page 96 and 97:

10. MAINTENANCE10.2 Indicator Remov

- Page 98 and 99:

10. MAINTENANCEConverter CaseVortex

- Page 100 and 101:

10. MAINTENANCE(3) Mass Flow calcul

- Page 102 and 103:

● No output is indicated when the

- Page 104 and 105:

11. TROUBLESHOOTING11.2 Flow (Only

- Page 106 and 107:

12. GENERAL DESCRIPTION12.2 Standar

- Page 108 and 109:

12. GENERAL DESCRIPTIONAmbient Temp

- Page 110 and 111:

12. GENERAL DESCRIPTIONTable 12.3.1

- Page 112 and 113:

12. GENERAL DESCRIPTION12.4 Option

- Page 114 and 115:

12.4.2 Option Multi-Variable (Build

- Page 116 and 117:

12. GENERAL DESCRIPTION12.4.4 Optio

- Page 118 and 119:

12. GENERAL DESCRIPTIONItemSpecific

- Page 120 and 121:

12. GENERAL DESCRIPTION■ Detailed

- Page 122 and 123:

12. GENERAL DESCRIPTIONTable 12.5.5

- Page 124 and 125:

12. GENERAL DESCRIPTION12.6 Externa

- Page 126 and 127:

φC12. GENERAL DESCRIPTION■ Flang

- Page 128 and 129:

12. GENERAL DESCRIPTION■ High Pro

- Page 130 and 131:

12. GENERAL DESCRIPTION■ Reduced

- Page 132 and 133:

12. GENERAL DESCRIPTION■ High Pro

- Page 134 and 135:

φJ12. GENERAL DESCRIPTION■ Reduc

- Page 136 and 137:

12. GENERAL DESCRIPTION Stainless S

- Page 138 and 139:

12. GENERAL DESCRIPTION Stainless S

- Page 140 and 141:

φJ12. GENERAL DESCRIPTION Stainles

- Page 142 and 143:

12. GENERAL DESCRIPTION Remote Type

- Page 144 and 145:

13. EXPLOSION PROTECTED TYPE INSTRU

- Page 146 and 147:

13. EXPLOSION PROTECTED TYPE INSTRU

- Page 148 and 149:

13. EXPLOSION PROTECTED TYPE INSTRU

- Page 150 and 151:

13. EXPLOSION PROTECTED TYPE INSTRU

- Page 152 and 153:

13. EXPLOSION PROTECTED TYPE INSTRU

- Page 154 and 155:

13. EXPLOSION PROTECTED TYPE INSTRU

- Page 156 and 157:

14. PRESSURE EQUIPMENT DIRECTIVE14.

- Page 158 and 159:

INSTALLATION AND OPERATING PRECAUTI

- Page 160 and 161:

REVISION RECORDREVISION RECORDTitle

- Page 162 and 163:

REVISION RECORDEdition10th11thDateN

- Page 164:

REVISION RECORDEdition14thDateMar.

![[MI 019-120] I/A Series Mass Flowtubes Models CFS20 ... - Invensys](https://img.yumpu.com/48832334/1/190x245/mi-019-120-i-a-series-mass-flowtubes-models-cfs20-invensys.jpg?quality=85)