IM 01F06A00-01EN 14th Edition - Yokogawa

IM 01F06A00-01EN 14th Edition - Yokogawa

IM 01F06A00-01EN 14th Edition - Yokogawa

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

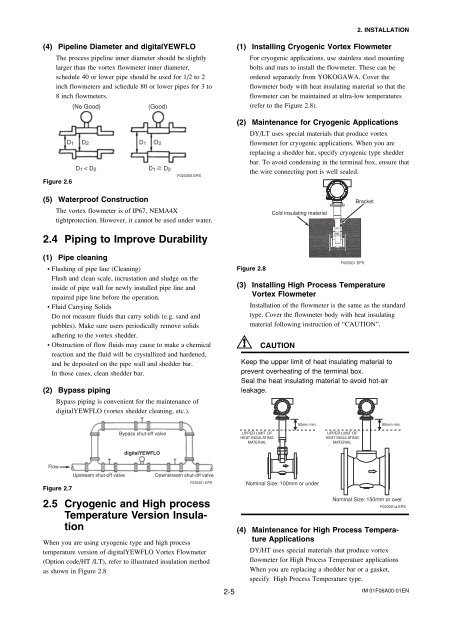

2. INSTALLATION(4) Pipeline Diameter and digitalYEWFLOThe process pipeline inner diameter should be slightlylarger than the vortex flowmeter inner diameter,schedule 40 or lower pipe should be used for 1/2 to 2inch flowmeters and schedule 80 or lower pipes for 3 to8 inch flowmeters.(No Good)(Good)(1) Installing Cryogenic Vortex FlowmeterFor cryogenic applications, use stainless steel mountingbolts and nuts to install the flowmeter. These can beordered separately from YOKOGAWA. Cover theflowmeter body with heat insulating material so that theflowmeter can be maintained at ultra-low temperatures(refer to the Figure 2.8).Figure 2.6D 1 D 2 D 1 D 2D 1 < D 2 D 1 D 2F020305.EPS(2) Maintenance for Cryogenic ApplicationsDY/LT uses special materials that produce vortexflowmeter for cryogenic applications. When you arereplacing a shedder bar, specify cryogenic type shedderbar. To avoid condensing in the terminal box, ensure thatthe wire connecting port is well sealed.(5) Waterproof ConstructionThe vortex flowmeter is of IP67, NEMA4Xtightprotection. However, it cannot be used under water.2.4 Piping to Improve DurabilityCold insulating materialBracket(1) Pipe cleaning• Flushing of pipe line (Cleaning)Flush and clean scale, incrustation and sludge on theinside of pipe wall for newly installed pipe line andrepaired pipe line before the operation.• Fluid Carrying SolidsDo not measure fluids that carry solids (e.g. sand andpebbles). Make sure users periodically remove solidsadhering to the vortex shedder.• Obstruction of flow fluids may cause to make a chemicalreaction and the fluid will be crystallized and hardened,and be deposited on the pipe wall and shedder bar.In those cases, clean shedder bar.(2) Bypass pipingBypass piping is convenient for the maintenance ofdigitalYEWFLO (vortex shedder cleaning, etc.).Figure 2.8F020501.EPS(3) Installing High Process TemperatureVortex FlowmeterInstallation of the flowmeter is the same as the standardtype. Cover the flowmeter body with heat insulatingmaterial following instruction of “CAUTION”.CAUTIONKeep the upper limit of heat insulating material toprevent overheating of the terminal box.Seal the heat insulating material to avoid hot-airleakage.Bypass shut-off valvedigitalYEWFLOUPPER L<strong>IM</strong>IT OFHEAT INSULATINGMATERIAL50mm min.UPPER L<strong>IM</strong>IT OFHEAT INSULATINGMATERIAL50mm min.FlowFigure 2.7Upstream shut-off valveDownstream shut-off valveF020401.EPS2.5 Cryogenic and High processTemperature Version InsulationWhen you are using cryogenic type and high processtemperature version of digitalYEWFLO Vortex Flowmeter(Option code/HT /LT), refer to illustrated insulation methodas shown in Figure 2.8Nominal Size: 100mm or underNominal Size: 150mm or overF020501a.EPS(4) Maintenance for High Process TemperatureApplicationsDY/HT uses special materials that produce vortexflowmeter for High Process Temperature applicationsWhen you are replacing a shedder bar or a gasket,specify High Process Temperature type.2-5 <strong>IM</strong> <strong>01F06A00</strong>-<strong>01EN</strong>

![[MI 019-120] I/A Series Mass Flowtubes Models CFS20 ... - Invensys](https://img.yumpu.com/48832334/1/190x245/mi-019-120-i-a-series-mass-flowtubes-models-cfs20-invensys.jpg?quality=85)