IM 01F06A00-01EN 14th Edition - Yokogawa

IM 01F06A00-01EN 14th Edition - Yokogawa

IM 01F06A00-01EN 14th Edition - Yokogawa

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

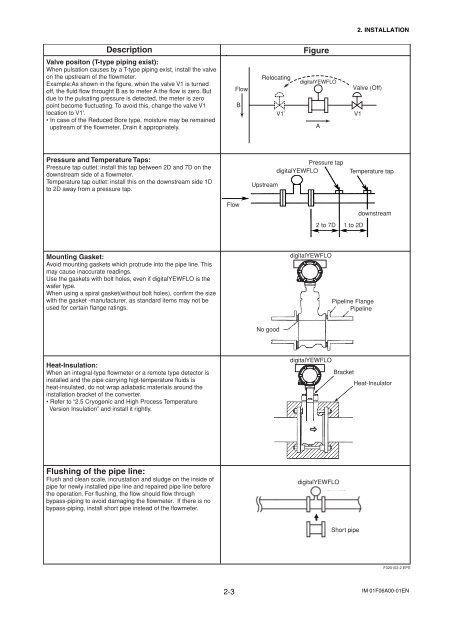

2. INSTALLATIONDescriptionValve positon (T-type piping exist):When pulsation causes by a T-type piping exist, install the valveon the upstream of the flowmeter.Example:As shown in the figure, when the valve V1 is turnedoff, the fluid flow throught B as to meter A the flow is zero. Butdue to the pulsating pressure is detected, the meter is zeropoint become fluctuating. To avoid this, change the valve V1location to V1'.• In case of the Reduced Bore type, moisture may be remainedupstream of the flowmeter. Drain it appropriately.FlowBFigureRelocatingdigitalYEWFLOValve (Off)V1’ V1APressure and Temperature Taps:Pressure tap outlet: install this tap between 2D and 7D on thedownstream side of a flowmeter.Temperature tap outlet: install this on the downstream side 1Dto 2D away from a pressure tap.UpstreamPressure tapdigitalYEWFLOTemperature tapFlow2 to 7D 1 to 2DdownstreamMounting Gasket:Avoid mounting gaskets which protrude into the pipe line. Thismay cause inaccurate readings.Use the gaskets with bolt holes, even if digitalYEWFLO is thewafer type.When using a spiral gasket(without bolt holes), confirm the sizewith the gasket -manufacturer, as standard items may not beused for certain flange ratings.digitalYEWFLOPipeline FlangePipelineNo goodHeat-Insulation:When an integral-type flowmeter or a remote type detector isinstalled and the pipe carrying higt-temperature fluids isheat-insulated, do not wrap adiabatic materials around theinstallation bracket of the converter.• Refer to “2.5 Cryogenic and High Process TemperatureVersion Insulation” and install it rightly.digitalYEWFLOBracketHeat-InsulatorFlushing of the pipe line:Flush and clean scale, incrustation and sludge on the inside ofpipe for newly installed pipe line and repaired pipe line beforethe operation. For flushing, the flow should flow throughbypass-piping to avoid damaging the flowmeter. If there is nobypass-piping, install short pipe instead of the flowmeter.digitalYEWFLOShort pipeF020102-2.EPS2-3 <strong>IM</strong> <strong>01F06A00</strong>-<strong>01EN</strong>

![[MI 019-120] I/A Series Mass Flowtubes Models CFS20 ... - Invensys](https://img.yumpu.com/48832334/1/190x245/mi-019-120-i-a-series-mass-flowtubes-models-cfs20-invensys.jpg?quality=85)