BROOKFIELD DV-II+ PROGRAMMABLE VISCOMETER Operating ...

BROOKFIELD DV-II+ PROGRAMMABLE VISCOMETER Operating ...

BROOKFIELD DV-II+ PROGRAMMABLE VISCOMETER Operating ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

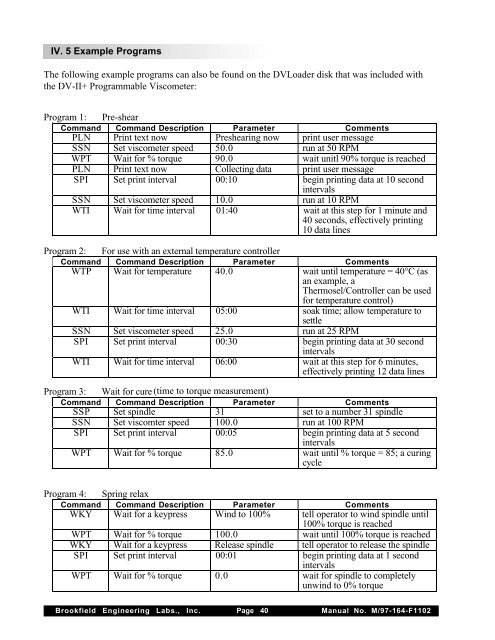

IV. 5 Example ProgramsThe following example programs can also be found on the <strong>DV</strong>Loader disk that was included withthe <strong>DV</strong>-<strong>II+</strong> Programmable Viscometer:Program 1: Pre-shearCommand Command Description Parameter CommentsPLN Print text now Preshearing now print user messageSSN Set viscometer speed 50.0 run at 50 RPMWPT Wait for % torque 90.0 wait unitl 90% torque is reachedPLN Print text now Collecting data print user messageSPI Set print interval 00:10 begin printing data at 10 secondintervalsSSN Set viscometer speed 10.0 run at 10 RPMWTI Wait for time interval 01:40 wait at this step for 1 minute and40 seconds, effectively printing10 data linesProgram 2: For use with an external temperature controllerCommand Command Description Parameter CommentsWTP Wait for temperature 40.0 wait until temperature = 40°C (asan example, aThermosel/Controller can be usedfor temperature control)WTI Wait for time interval 05:00 soak time; allow temperature tosettleSSN Set viscometer speed 25.0 run at 25 RPMSPI Set print interval 00:30 begin printing data at 30 secondintervalsWTI Wait for time interval 06:00 wait at this step for 6 minutes,effectively printing 12 data linesProgram 3: Wait for cure (time to torque measurement)Command Command Description Parameter CommentsSSP Set spindle 31 set to a number 31 spindleSSN Set viscomter speed 100.0 run at 100 RPMSPI Set print interval 00:05 begin printing data at 5 secondintervalsWPT Wait for % torque 85.0 wait until % torque = 85; a curingcycleProgram 4: Spring relaxCommand Command Description Parameter CommentsWKY Wait for a keypress Wind to 100% tell operator to wind spindle until100% torque is reachedWPT Wait for % torque 100.0 wait until 100% torque is reachedWKY Wait for a keypress Release spindle tell operator to release the spindleSPI Set print interval 00:01 begin printing data at 1 secondintervalsWPT Wait for % torque 0.0 wait for spindle to completelyunwind to 0% torqueBrookfield Engineering Labs., Inc. Page 40 Manual No. M/97-164-F1102