Pneumatic cylinders - Duncan Rogers

Pneumatic cylinders - Duncan Rogers

Pneumatic cylinders - Duncan Rogers

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

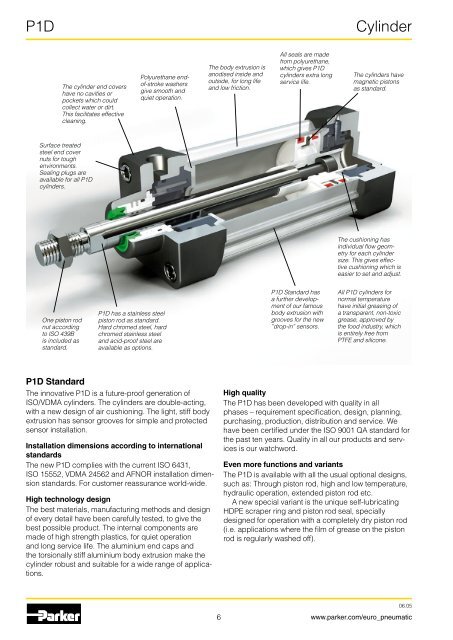

P1DCylinderThe cylinder end covershave no cavities orpockets which couldcollect water or dirt.This facilitates effectivecleaning.Polyurethane endof-strokewashersgive smooth andquiet operation.The body extrusion isanodised inside andoutside, for long lifeand low friction.All seals are madefrom polyurethane,which gives P1D<strong>cylinders</strong> extra longservice life.The <strong>cylinders</strong> havemagnetic pistonsas standard.Surface treatedsteel end covernuts for toughenvironments.Sealing plugs areavailable for all P1D<strong>cylinders</strong>.The cushioning hasindividual flow geometryfor each <strong>cylinders</strong>ize. This gives effectivecushioning which iseasier to set and adjust.One piston rodnut accordingto ISO 439Bis included asstandard.P1D has a stainless steelpiston rod as standard.Hard chromed steel, hardchromed stainless steeland acid-proof steel areavailable as options.P1D Standard hasa further developmentof our famousbody extrusion withgrooves for the new”drop-in” sensors.All P1D <strong>cylinders</strong> fornormal temperaturehave initial greasing ofa transparent, non-toxicgrease, approved bythe food industry, whichis entirely free fromPTFE and silicone.P1D StandardThe innovative P1D is a future-proof generation ofISO/VDMA <strong>cylinders</strong>. The <strong>cylinders</strong> are double-acting,with a new design of air cushioning. The light, stiff bodyextrusion has sensor grooves for simple and protectedsensor installation.Installation dimensions according to internationalstandardsThe new P1D complies with the current ISO 6431,ISO 15552, VDMA 24562 and AFNOR installation dimensionstandards. For customer reassurance world-wide.High technology designThe best materials, manufacturing methods and designof every detail have been carefully tested, to give thebest possible product. The internal components aremade of high strength plastics, for quiet operationand long service life. The aluminium end caps andthe torsionally stiff aluminium body extrusion make thecylinder robust and suitable for a wide range of applications.High qualityThe P1D has been developed with quality in allphases – requirement specification, design, planning,purchasing, production, distribution and service. Wehave been certified under the ISO 9001 QA standard forthe past ten years. Quality in all our products and servicesis our watchword.Even more functions and variantsThe P1D is available with all the usual optional designs,such as: Through piston rod, high and low temperature,hydraulic operation, extended piston rod etc.A new special variant is the unique self-lubricatingHDPE scraper ring and piston rod seal, speciallydesigned for operation with a completely dry piston rod(i.e. applications where the film of grease on the pistonrod is regularly washed off).06.05www.parker.com/euro_pneumatic