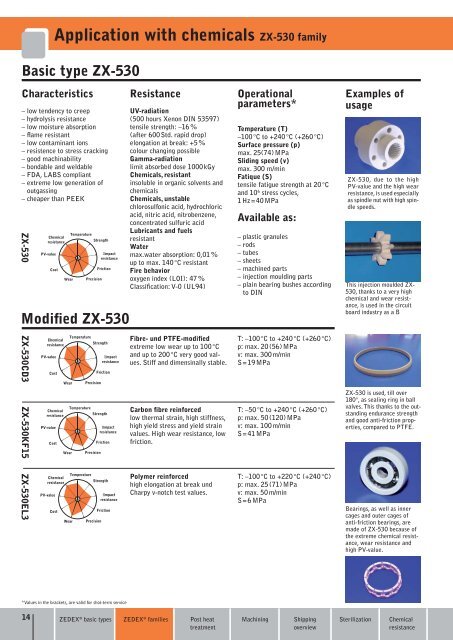

Application with chemicals ZX-530 familyBasic type ZX-530Characteristics– low tendency to creep– hydrolysis resistance– low moisture absorption– flame resistant– low contaminant ions– resistence to stress cracking– good machinability– bondable and weldable– FDA, LABS compliant– extreme low generation ofoutgassing– cheaper than PEEKZX-530ChemicalresistancePV-valueCostWearTemperatureStrengthPrecisionmpactresistanceFrictionModified ZX-530ResistanceUV-radiation(500 hours Xenon DIN 53597)tensile strength: –16 %(after 600 Std. rapid drop)elongation at break: +5 %colour changing possibleGamma-radiationlimit absorbed dose 1000 kGyChemicals, resistantinsoluble in organic solvents andchemicalsChemicals, unstablechlorosulfonic acid, hydrochloricacid, nitric acid, nitrobenzene,concentrated sulfuric acidLubricants and fuelsresistantWatermax.water absorption: 0,01 %up to max. 140 °C resistantFire behavioroxygen index (LOI): 47 %Classification: V-0 (UL94)Operationalparameters*Temperature (T)–100 °C to +240 °C (+260 °C)Surface pressure (p)max. 25(74) MPaSliding speed (v)max. 300 m /minFatique (S)tensile fatigue strength at 20 °Cand 10 6 stress cycles,1 Hz = 40 MPaAvailable as:– plastic <strong>granules</strong>– rods– tubes– sheets– machined parts– injection moulding parts– plain bearing bushes accordingto DINExamples ofusageZX-530, due to the highPV-value and the high wearresistance, is used especiallyas spindle nut with high spindlespeeds.This injection moulded ZX-530, thanks to a very highchemical and wear resistance,is used in the circuitboard industry as a BZX-530CD3 ZX-530KF15 ZX-530EL3ChemicalresistancePV-valueCostChemicalresistancePV-valueCostChemicalresistancePV-valueCostWearWearTemperatureStrengthPrecisionmpactresistanceFrictionTemperatureStrengthWearPrecisionmpactresistanceFrictionTemperatureStrengthPrecisionmpactresistanceFrictionFibre- und PTFE-modifiedextreme low wear up to 100 °Cand up to 200 °C very good values.Stiff and dimensinally stable.Carbon fibre reinforcedlow thermal strain, high stiffness,high yield stress and yield strainvalues. High wear resistance, lowfriction.Polymer reinforcedhigh elongation at break undCharpy v-notch test values.T: –100 °C to +240 °C (+260 °C)p: max. 20 (56) MPav: max. 300 m/minS = 19 MPaT: –50 °C to +240 °C (+260 °C)p: max. 50 (120) MPav: max. 100 m/minS = 41 MPaT: –100 °C to +220 °C (+240 °C)p: max. 25 (71) MPav: max. 50 m/minS = 6 MPaZX-530 is used, till over180°, as sealing ring in ballvalves. This thanks to the outstandingendurance strengthand good anti-friction properties,compared to PTFE.Bearings, as well as innercages and outer cages ofanti-friction bearings, aremade of ZX-530 because ofthe extreme chemical resistance,wear resistance andhigh PV-value.*Values in the brackets, are valid for shot-term service14 ZEDEX ® basic types ZEDEX ® families Post heattreatmentMachiningShippingoverviewSterilizationChemicalresistance

SubstitutionexamplesWhich material can replacethe the ZX-530?PEEKtaking into account the permissibleoperation temperatureand the strength required,replaceableTargets: cost reduction,wear and friction reduction,increment of the chemicalresistance and of the PVvalue.PTFE and PTFE Compoundsno replaceable in circumstanceof concentrated sulfuric,nitric, and chlorosulfonicacid and where, an extremelyhigh requirement of frictioncoefficient reduction, isrequested.Targets: wear reduction,improvement of the stiffnessand precision. Reductionof the plastic deformationespecially with hightemperature, cost reductionthrough injection moulding.Increment of the PV-value.PVDFTargets: improvement ofthe chemical resistance,increment of the thermalapplication limit. Wearreduction and increment ofthe stiffness and hardness.PCTFE, ETFETargets: improvement ofthe chemical resistance,increament of the thermalapplication limit, stiffnessand hardness. Cost reductionthrough injection moulding.Ceramictaking into account theoperating temperature range,hardness and chemical resistancerequired, replaceable.Targets: increment of theheat shock resistance andbrittleness, reduction of theproject outlay, reduction of thesensitivity to edge pressure,cost reduction.Stress / Strain (ISO 527) Flexural E-Modulus (ISO 178)Stress [MPa]1008060402000 2 4 6 8 10 12 14 16Strain [%]Defiance a fibre reinforcement, ZX-530KF15 has got an elongationat break of 5 %. The polymer reinforced ZX-530EL3 hasgot an elogation at break of 15 %.Admissible PV-value Thermal expansion coefficient (ISO E830)p x v value [MPa x m/min]1008060402001 10 100Sliding speed [m/min]The PV-values of all the types of ZX-530 are significantly higherthan the PEEK´s ones. PTFE offers a maximum PV-value of2 MPa m /min.Impact resistance notched (ISO179/1eA)Impact strenght notched [kJ/m²]1401201008014121086420ZX-530ZX-530CD3ZX-530KF15ZX-530EL3PEEKZX-530EL3 has got the highes Charpy v-notch test value.ZX-530 is at the level of PEEK.ZX-530ZX-530CD3ZX-530KF15ZX-530EL3PEEKPTFEZX-530ZX-530CD3ZX-530KF15ZX-530EL3PEEKPTFE-196 -70 23 60 100Temperature [°C]Coefficient of friction in dry running25–100 °C, on X5CrNi18.9 hard-chrome plated, Rz 2 μm, 0,5-5 MPa0,350,30μ dyn.μ stat.Flexural E-Modulus [MPa]5.0004.0003.0002.0001.0000From 90 °C, the modulus in flexure of the ZX-530 declines andfrom 180 °C, is at the same level of PEEK. ZX-530EL3 has gota low modulus in flexure.Coefficient of thermal expansion [1x10 -5 /K]302520151050ZX-530KF15 and ZX-530CD3 are more dimensionally stablethan PEEK and equally good as the ZX-530.WearWear [mm/100km]100,0010,0020 40 60 80 100 120 140 160 180 200 220 240Temperature [°C]ZX-530ZX-530CD3ZX-530KF15ZX-530EL3PEEKPTFE20 40 60 80 100 120 140 160 180 200 220 2401,000,100,01Temperature [°C]ZX-530ZX-530CD3ZX-530KF15ZX-530ZX-530CD3ZX-530KF15ZX-530EL3PEEKPTFE20 40 60 80 100 120 140 160 180 200 220 240Temperature [°C]ZX-530EL3PEEKPTFEZX-530CD3 offers up to 100 °C an extreme high wear resistance.Even polyimide, PAI or strong reinforced plastics areworse.Coefficient of friction with oil lubrication25–100 °C, on X5CrNi18.9 hard-chrome plated, Rz 2 μm, 0,5-5 MPa, oil: OL-J46 DIN 515020,350,30μ dyn.μ stat.Friction coefficient0,250,200,150,100,250,200,150,100,050,050,000,00PEEKZX-530ZX-530EL3ZX-530CD3ZX-530KF15PTFEZX-324/PEEKZX-530ZX-530EL3ZX-530CD3Friction CoefficientZX-530KF15PTFEZEDEX ® basic typesZEDEX ® familiesPost heattreatmentMachiningShippingoverviewSterilizationChemicalresistance15

- Page 1 and 2: ZEDEX ®Tribological Polymer Soluti

- Page 3 and 4: Stamping (Hot forming) . . . . . .

- Page 5 and 6: Thermal limitation usage of ZEDEX

- Page 7 and 8: Comparison of the relative characte

- Page 9 and 10: SubstitutionexamplesWhich material

- Page 11 and 12: SubstitutionexamplesWhich material

- Page 16 and 17: Low friction ZX-550 familyBasic typ

- Page 18 and 19: Long-term up to 300 °C ZX-750 fami

- Page 20 and 21: Comparison table of the ZEDEX ® ma

- Page 22 and 23: Post heat treatmentThe plastic is s

- Page 24 and 25: Degree of crystallinitySemi-crystal

- Page 26 and 27: Machining guidelineZX-100KZX-100EL6

- Page 28 and 29: SawingThe band saw cut speed should

- Page 30 and 31: ReamingVery tight bore tolerances a

- Page 32 and 33: Achievable lathe turning and millin

- Page 34 and 35: Shipping overviewShipping overview

- Page 36 and 37: Shipping overview of semi-finished

- Page 38 and 39: Size list of sheetsMaterialThicknes

- Page 40 and 41: Size list of sheetsMaterialThicknes

- Page 42 and 43: Size list of rods and tubes, made o

- Page 44 and 45: Size list of rods and tubes, made o

- Page 46 and 47: Size list of rods and tubes, made o

- Page 48 and 49: Size list of rods and tubes, made o

- Page 50 and 51: Size list of rods and tubes, made o

- Page 52 and 53: Size list of rods and tubes, made o

- Page 55 and 56: 55ZEDEX ® basic types ZEDEX ® fam

- Page 57 and 58: 57ZEDEX ® basic types ZEDEX ® fam

- Page 59 and 60: Size list of rods and tubes, made o

- Page 61 and 62: 61ZEDEX ® basic types ZEDEX ® fam

- Page 63 and 64:

Size list of rods and tubes, made o

- Page 65 and 66:

65ZEDEX ® basic types ZEDEX ® fam

- Page 67 and 68:

Size list of rods and tubes, made o

- Page 69 and 70:

69ZEDEX ® basic types ZEDEX ® fam

- Page 71 and 72:

Size list of rods and tubes, made o

- Page 73 and 74:

Size list of rods and tubes, made o

- Page 75 and 76:

Size list of rods and tubes, made o

- Page 77 and 78:

SterilizationIntroductionThe word s

- Page 79 and 80:

High energy radiationThe radiation

- Page 81 and 82:

Chemical resistanceIntroductionThe

- Page 83 and 84:

Chemical resistance of the ZEDEX ®

- Page 85 and 86:

Chemicals listmaterialschemical / c

- Page 87 and 88:

Chemicals listmaterialschemical / c

- Page 89 and 90:

Chemicals listmaterialschemical / c

- Page 91 and 92:

Chemicals listmaterialschemical / c

- Page 93 and 94:

Chemicals listmaterialschemical / c

- Page 95 and 96:

Chemicals listmaterialschemical / c

- Page 97 and 98:

Chemicals listmaterialschemical / c

- Page 99 and 100:

Chemicals listmaterialschemical / c

- Page 101 and 102:

Chemicals listmaterialschemical / c

- Page 103 and 104:

Chemicals listmaterialschemical / c

- Page 105 and 106:

Chemicals listmaterialschemical / c

- Page 107 and 108:

Chemicals listmaterialschemical / c

- Page 109 and 110:

Chemicals listmaterialschemical / c

- Page 111 and 112:

Chemicals listmaterialschemical / c

- Page 113 and 114:

Chemicals listmaterialschemical / c

- Page 115 and 116:

Chemicals listmaterialschemical / c

- Page 117 and 118:

Synonym listSynonymsName from chemi

- Page 119 and 120:

Synonym listSynonymsoldhamiteoxacyc

- Page 121 and 122:

Chemical group listThe chemicals gr

- Page 123 and 124:

Legal informationAll the tests are