Semi-finished products Plastic granules Special compounds

Semi-finished products Plastic granules Special compounds

Semi-finished products Plastic granules Special compounds

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

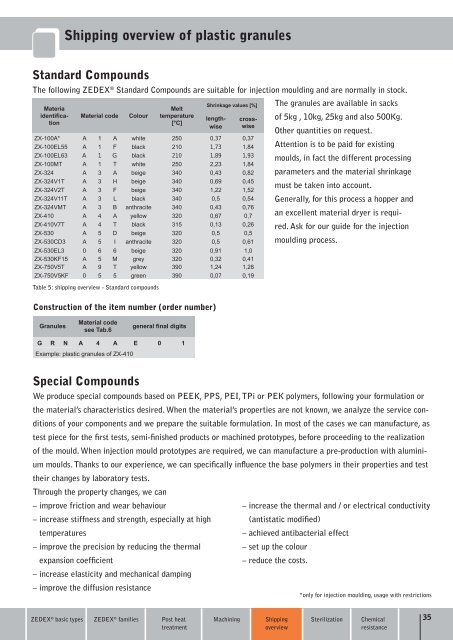

Shipping overview of plastic <strong>granules</strong>Standard CompoundsThe following ZEDEX ® Standard Compounds are suitable for injection moulding and are normally in stock.Shrinkage values [%] The <strong>granules</strong> are available in sacksMateriaMeltidentification[°C]Material code Colour temperaturelengthwiswisecross-of 5kg , 10kg, 25kg and also 500Kg.Other quantities on request.Attention is to be paid for existingmoulds, in fact the different processingparameters and the material shrinkagemust be taken into account.Generally, for this process a hopper andan excellent material dryer is required.Ask for our guide for the injectionmoulding process.ZX-100A* A 1 A white 250 0,37 0,37ZX-100EL55 A 1 F black 210 1,73 1,84ZX-100EL63 A 1 G black 210 1,89 1,93ZX-100MT A 1 T white 250 2,23 1,84ZX-324 A 3 A beige 340 0,43 0,82ZX-324V1T A 3 H beige 340 0,69 0,45ZX-324V2T A 3 F beige 340 1,22 1,52ZX-324V11T A 3 L black 340 0,5 0,54ZX-324VMT A 3 B anthracite 340 0,43 0,76ZX-410 A 4 A yellow 320 0,67 0,7ZX-410V7T A 4 T black 315 0,13 0,26ZX-530 A 5 D beige 320 0,5 0,5ZX-530CD3 A 5 I anthracite 320 0,5 0,61ZX-530EL3 0 6 6 beige 320 0,91 1,0ZX-530KF15 A 5 M grey 320 0,32 0,41ZX-750V5T A 9 T yellow 390 1,24 1,28ZX-750V5KF 0 5 5 green 390 0,07 0,19Table 5: shipping overview - Standard <strong>compounds</strong>Construction of the item number (order number)GranulesMaterial codesee Tab.6general final digitsG R N A 4 A E 0 1Example: plastic <strong>granules</strong> of ZX-410<strong>Special</strong> CompoundsWe produce special <strong>compounds</strong> based on PEEK, PPS, PEI, TPi or PEK polymers, following your formulation orthe material’s characteristics desired. When the material’s properties are not known, we analyze the service conditionsof your components and we prepare the suitable formulation. In most of the cases we can manufacture, astest piece for the first tests, semi-<strong>finished</strong> <strong>products</strong> or machined prototypes, before proceeding to the realizationof the mould. When injection mould prototypes are required, we can manufacture a pre-production with aluminiummoulds. Thanks to our experience, we can specifically influence the base polymers in their properties and testtheir changes by laboratory tests.Through the property changes, we can– improve friction and wear behaviour– increase stiffness and strength, especially at hightemperatures– improve the precision by reducing the thermalexpansion coefficient– increase elasticity and mechanical damping– improve the diffusion resistance– increase the thermal and / or electrical conductivity(antistatic modified)– achieved antibacterial effect– set up the colour– reduce the costs.*only for injection moulding, usage with restrictionsZEDEX ® basic types ZEDEX ® families Post heattreatmentMachiningShippingoverviewSterilizationChemicalresistance35