Allround up to 110 °C ZX-100 familyBasic type ZX-100KCharacteristics– hard, stiff, tough– high fatigue strength– good resistance to weathering– resistance to stress cracking– good machinability– bondable and weldable– FDA compliant, LABS compliant– PTFE- and Silicone-Free– KTW approved– low-outgassing– notch-sensitiveZX-100KChemicalresistanceV-valueCostWear00TemperatureStrengthrecisionmpactresistanceFrictionModified ZX-100ResistanceUV-radiation(1000 hours Xenon DIN 53597)tensile strength: –25 %,elongation at break: –43 %Gamma-radiationlimit absorbed dose 1200 kGyChemicals, resistantaromatic and aliphatic hydrocarbons,weak acids and alkalisChemicals, not resistantstrong acids and alkalis, phenols,cresolsLubricants and fuelsresistantWatermax. water absorption: 0,3 %dimensional changes: 0,1 %up to max. 80 °C resistantFire behavioroxygen index (LOI): 24 %,classification: HB (UL94)Operationalparameters*Temperature (T)–100 °C to +110 °C (+140 °C)surface pressure (p)max. 35 (75) MPaSliding speed (v)max. 100 m /minFatigue (S)tensile fatigue strength at 20 °Cand 10 6 stress cycles,1 Hz = 52 MPaImpacts, vibrations, edge loading,outdoor use, underwater use.Allround-plastic up to 110°C.Available as:– plastic <strong>granules</strong>– rods– tubes– sheets– machined parts– plain bearing bushes accordingto DINExamples ofusageA trapezoidal thread nut(TR40) carries more than 5t,for Kfz-lifting platforms.ZX-100K is placed withoutbacklash in actuating units.Glue can be easily removedfrom the ZX-100K mouldwiper.ZX-100AChemicalresistanceV-valueCostWearTemperatureStrengthrecisionmpactresistanceFrictionStrong amorphous structuretougher, more elastic, softer,only injection moulding possible,reduced precision.T: –100 °C to +55 °C (+75 °C)p: max. 20 (60) MPav: max. 40 m /minS = 40 MPalow-cost solution for large-scalemanufacturing, with low precisionand temperature requirements.ZX-100K, with a modulus(m) =5 mm, transmits 38 kWin a dry running condition.ZX-100EL55ZX-100EL63ZX-100MTChemicalresistanceV-valueCostChemicalresistanceV-valueCostWearTemperatureStrengthWearrecisionmpactresistanceFrictionTemperatureStrengthrecisionmpactresistanceFrictionElastomer-modifiedrubbery, grip,soft elongation >300 %, highimpact absorption, high impactresistantZX-100EL63 (63 Shore D)ZX-100EL55 (55 Shore D).Mineral-reinforcedstiffer, harder, ultra-high strength,no fibre reinforcement.T: –50 °C to +55 °C (+75 °C)p: max. 3 (10) MPav: max. 10 m /minS = 9 MPasolution for stressed parts subjectto strong abrasive wear anderosive wear.T: –40 °C to +80 °C (+130 °C)p: max. 28 (85) MPav: max. 150 m /minS = 42 MPalow-cost solution for heavystressedparts up to 80 °C andlow sliding speed.ZX-100K drives plungerswith a peak load of 120MPaand with 1μm thicknesstolerance. It is used as mainbearing of the measuringdevices.ZX-100K is mounted onwater-use-pumps up to 1000kW, chassis of trucks andexcavators, and it works in arough and dirty condition.*Values in the brackets, are valid for shot-term service8 ZEDEX ® basic types ZEDEX ® families Post heattreatmentMachiningShippingoverviewSterilizationChemicalresistance

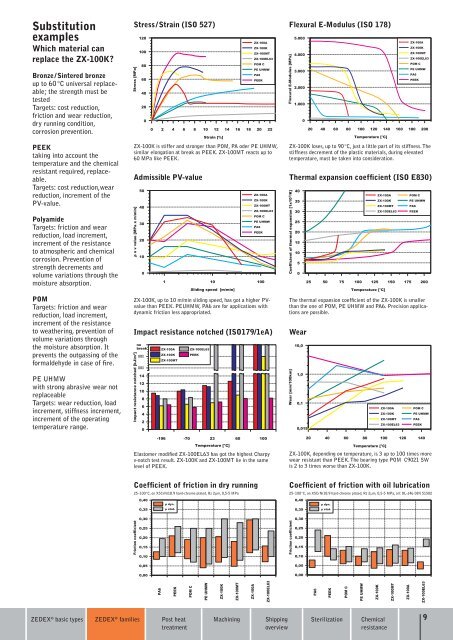

SubstitutionexamplesWhich material canreplace the ZX-100K?Bronze / Sintered bronzeup to 60 °C universal replaceable;the strength must betestedTargets: cost reduction,friction and wear reduction,dry running condition,corrosion prevention.PEEKtaking into account thetemperature and the chemicalresistant required, replaceable.Targets: cost reduction,wearreduction, increment of thePV-value.PolyamideTargets: friction and wearreduction, load increment,increment of the resistanceto atmospheric and chemicalcorrosion. Prevention ofstrength decrements andvolume variations through themoisture absorption.POMTargets: friction and wearreduction, load increment,increment of the resistanceto weathering, prevention ofvolume variations throughthe moisture absorption. Itprevents the outgassing of theformaldehyde in case of fire.PE UHMWwith strong abrasive wear notreplaceableTargets: wear reduction, loadincrement, stiffness increment,increment of the operatingtemperature range.Stress / Strain (ISO 527) Flexural E-Modulus (ISO 178)Stress [MPa]p x v value [MPa x m/min]120100806040205040302010000 2 4 6 8 10 12 14 16 18 20 22Strain [%]1 10 100Sliding speed [m/min]ZX-100AZX-100KZX-100MTZX-100EL63POM CPE UHMWPA6PEEKZX-100K is stiffer and stronger than POM, PA oder PE UHMW,similar elongation at break as PEEK. ZX-100MT reacts up to60 MPa like PEEK.Impact resistance notched [kJ/m²]nobreak14121086420ZX-100AZX-100KZX-100MTZX-100EL63PEEKZX-100AZX-100KZX-100MTZX-100EL63POM CPE UHMWPA6PEEKFlexural E-Modulus [MPa]Coefficient of thermal expansion [1x10 -5 /K]Wear [mm/100km]5.0004.0003.0002.0001.000403530252015105010,01,00,100,01520 40 60 80 100 120 140 160 180 200Temperature [°C]ZX-100AZX-100K25 50 75 100 125 150 175 200Temperature [°C]ZX-100MTZX-100EL63ZX-100AZX-100KZX-100MTZX-100EL63ZX-100AZX-100KZX-100MTZX-100EL63POM CPE UHMWAdmissible PV-value Thermal expansion coefficient (ISO E830)ZX-100K, up to 10 m /min sliding speed, has got a higher PVvaluethan PEEK. PEUHMW, PA6 are for applications withdynamic friction less appropriated.Impact resistance notched (ISO179/1eA)PA6PEEKZX-100K loses, up to 90 °C, just a little part of its stiffness. Thestiffness decrement of the plastic materials, during elevatedtemperature, must be taken into consideration.POM CPE UHMWPA6PEEKThe thermal expansion coefficient of the ZX-100K is smallerthan the one of POM, PE UHMW and PA6. Precision applicationsare possible.WearPOM CPE UHMWPA6PEEK-196 -70 23 60 100Temperature [°C]Elastomer modified ZX-100EL63 has got the highest Charpyv-notch test result. ZX-100K and ZX-100MT lie in the samelevel of PEEK.20 40 60 80 100 120 140Temperature [°C]ZX-100K, depending on temperature, is 3 up to 100 times morewear resistant than PEEK. The bearing type POM C9021 SWis 2 to 3 times worse than ZX-100K.Coefficient of friction in dry running25–100 °C, on X5CrNi18.9 hard-chrome plated, Rz 2 μm, 0,5-5 MPaFriction coefficient0,40μ dyn.0,35μ stat.0,300,250,200,150,100,050,00PA6ZX-324/PEEKPOM CPE UHMWZX-100KZX-100MTZX-100AZX-100EL63Friction coefficient0,40μ dyn.0,35μ stat.0,300,250,200,150,100,050,00Coefficient of friction with oil lubrication25–100 °C, on X5CrNi18.9 hard-chrome plated, Rz 2 μm, 0,5-5 MPa, oil: OL-J46 DIN 51502PA6PEEKPOM CPE UHMWZX-100KZX-100MTZX-100AZX-100EL63ZEDEX ® basic typesZEDEX ® familiesPost heattreatmentMachiningShippingoverviewSterilizationChemicalresistance9

- Page 1 and 2: ZEDEX ®Tribological Polymer Soluti

- Page 3 and 4: Stamping (Hot forming) . . . . . .

- Page 5 and 6: Thermal limitation usage of ZEDEX

- Page 7: Comparison of the relative characte

- Page 11 and 12: SubstitutionexamplesWhich material

- Page 14 and 15: Application with chemicals ZX-530 f

- Page 16 and 17: Low friction ZX-550 familyBasic typ

- Page 18 and 19: Long-term up to 300 °C ZX-750 fami

- Page 20 and 21: Comparison table of the ZEDEX ® ma

- Page 22 and 23: Post heat treatmentThe plastic is s

- Page 24 and 25: Degree of crystallinitySemi-crystal

- Page 26 and 27: Machining guidelineZX-100KZX-100EL6

- Page 28 and 29: SawingThe band saw cut speed should

- Page 30 and 31: ReamingVery tight bore tolerances a

- Page 32 and 33: Achievable lathe turning and millin

- Page 34 and 35: Shipping overviewShipping overview

- Page 36 and 37: Shipping overview of semi-finished

- Page 38 and 39: Size list of sheetsMaterialThicknes

- Page 40 and 41: Size list of sheetsMaterialThicknes

- Page 42 and 43: Size list of rods and tubes, made o

- Page 44 and 45: Size list of rods and tubes, made o

- Page 46 and 47: Size list of rods and tubes, made o

- Page 48 and 49: Size list of rods and tubes, made o

- Page 50 and 51: Size list of rods and tubes, made o

- Page 52 and 53: Size list of rods and tubes, made o

- Page 55 and 56: 55ZEDEX ® basic types ZEDEX ® fam

- Page 57 and 58: 57ZEDEX ® basic types ZEDEX ® fam

- Page 59 and 60:

Size list of rods and tubes, made o

- Page 61 and 62:

61ZEDEX ® basic types ZEDEX ® fam

- Page 63 and 64:

Size list of rods and tubes, made o

- Page 65 and 66:

65ZEDEX ® basic types ZEDEX ® fam

- Page 67 and 68:

Size list of rods and tubes, made o

- Page 69 and 70:

69ZEDEX ® basic types ZEDEX ® fam

- Page 71 and 72:

Size list of rods and tubes, made o

- Page 73 and 74:

Size list of rods and tubes, made o

- Page 75 and 76:

Size list of rods and tubes, made o

- Page 77 and 78:

SterilizationIntroductionThe word s

- Page 79 and 80:

High energy radiationThe radiation

- Page 81 and 82:

Chemical resistanceIntroductionThe

- Page 83 and 84:

Chemical resistance of the ZEDEX ®

- Page 85 and 86:

Chemicals listmaterialschemical / c

- Page 87 and 88:

Chemicals listmaterialschemical / c

- Page 89 and 90:

Chemicals listmaterialschemical / c

- Page 91 and 92:

Chemicals listmaterialschemical / c

- Page 93 and 94:

Chemicals listmaterialschemical / c

- Page 95 and 96:

Chemicals listmaterialschemical / c

- Page 97 and 98:

Chemicals listmaterialschemical / c

- Page 99 and 100:

Chemicals listmaterialschemical / c

- Page 101 and 102:

Chemicals listmaterialschemical / c

- Page 103 and 104:

Chemicals listmaterialschemical / c

- Page 105 and 106:

Chemicals listmaterialschemical / c

- Page 107 and 108:

Chemicals listmaterialschemical / c

- Page 109 and 110:

Chemicals listmaterialschemical / c

- Page 111 and 112:

Chemicals listmaterialschemical / c

- Page 113 and 114:

Chemicals listmaterialschemical / c

- Page 115 and 116:

Chemicals listmaterialschemical / c

- Page 117 and 118:

Synonym listSynonymsName from chemi

- Page 119 and 120:

Synonym listSynonymsoldhamiteoxacyc

- Page 121 and 122:

Chemical group listThe chemicals gr

- Page 123 and 124:

Legal informationAll the tests are