Semi-finished products Plastic granules Special compounds

Semi-finished products Plastic granules Special compounds

Semi-finished products Plastic granules Special compounds

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

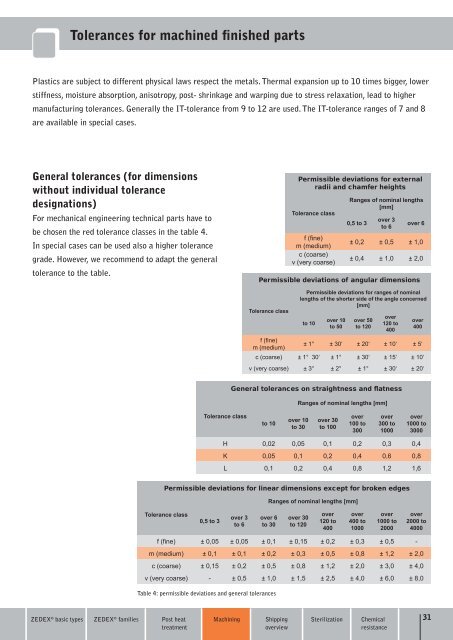

Tolerances for machined <strong>finished</strong> parts<strong>Plastic</strong>s are subject to different physical laws respect the metals. Thermal expansion up to 10 times bigger, lowerstiffness, moisture absorption, anisotropy, post- shrinkage and warping due to stress relaxation, lead to highermanufacturing tolerances. Generally the IT-tolerance from 9 to 12 are used. The IT-tolerance ranges of 7 and 8are available in special cases.General tolerances (for dimensionswithout individual tolerancedesignations)For mechanical engineering technical parts have tobe chosen the red tolerance classes in the table 4.In special cases can be used also a higher tolerancegrade. However, we recommend to adapt the generaltolerance to the table.Permissible deviations for externalradii and chamfer heightsTolerance classf (fi ne)m (medium)c (coarse)v (very coarse)Ranges of nominal lengths[mm]0,5 to 3over 3to 6over 6± 0,2 ± 0,5 ± 1,0± 0,4 ± 1,0 ± 2,0Permissible deviations of angular dimensionsTolerance classPermissible deviations for ranges of nominallengths of the shorter side of the angle concerned[mm]to 10over 10to 50over 50to 120over120 to400over400f (fine)m (medium)± 1° ± 30‘ ± 20‘ ± 10‘ ± 5‘c (coarse) ± 1° 30‘ ± 1° ± 30‘ ± 15‘ ± 10‘v (very coarse) ± 3° ± 2° ± 1° ± 30‘ ± 20‘General tolerances on straightness and flatnessRanges of nominal lengths [mm]Tolerance classto 10over 10to 30over 30to 100over100 to300over300 to1000over1000 to3000H 0,02 0,05 0,1 0,2 0,3 0,4K 0,05 0,1 0,2 0,4 0,6 0,8L 0,1 0,2 0,4 0,8 1,2 1,6Permissible deviations for linear dimensions except for broken edgesRanges of nominal lengths [mm]Tolerance class0,5 to 3over 3to 6over 6to 30over 30to 120over120 to400over400 to1000over1000 to2000over2000 to4000f (fine) ± 0,05 ± 0,05 ± 0,1 ± 0,15 ± 0,2 ± 0,3 ± 0,5 -m (medium) ± 0,1 ± 0,1 ± 0,2 ± 0,3 ± 0,5 ± 0,8 ± 1,2 ± 2,0c (coarse) ± 0,15 ± 0,2 ± 0,5 ± 0,8 ± 1,2 ± 2,0 ± 3,0 ± 4,0v (very coarse) - ± 0,5 ± 1,0 ± 1,5 ± 2,5 ± 4,0 ± 6,0 ± 8,0Table 4: permissible deviations and general tolerancesZEDEX ® basic types ZEDEX ® families Post heattreatmentMachiningShippingoverviewSterilizationChemicalresistance31