Semi-finished products Plastic granules Special compounds

Semi-finished products Plastic granules Special compounds

Semi-finished products Plastic granules Special compounds

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

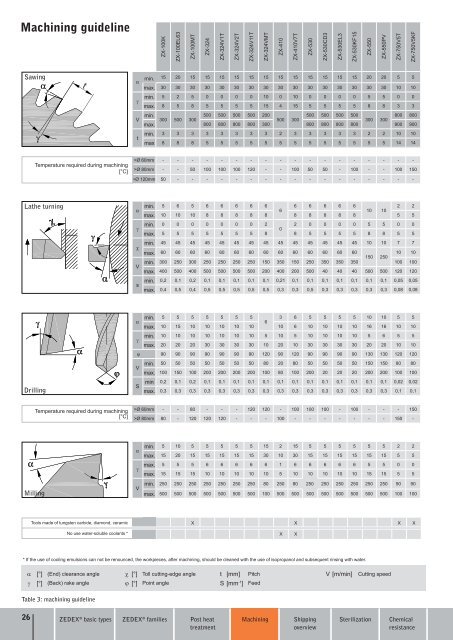

Machining guidelineZX-100KZX-100EL63ZX-100MTZX-324ZX-324V1TZX-324V2TZX-324V11TZX-324VMTZX-410ZX-410V7TZX-530ZX-530CD3ZX-530EL3ZX-530KF15ZX-550ZX-550PVZX-750V5TZX-750V5KFSawingα min. 15 20 15 15 15 15 15 15 15 15 15 15 15 15 20 20 5 5max. 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 30 10 10γmin. 5 2 5 0 0 0 0 10 0 10 0 0 0 0 5 5 0 0max. 8 5 8 5 5 5 5 15 4 15 5 5 5 5 8 8 3 3V min. 500 500 500 500 200500 500 500 500800 800300 500 300500 300300 300max. 800 800 800 800 300 800 800 800 800 900 900tmin. 3 3 3 3 3 3 3 3 2 3 3 3 3 3 2 2 10 10max 8 8 8 5 5 5 5 5 5 5 5 5 5 5 5 5 14 14Temperature required during machining[°C]>Ø 60mm - - - - - - - - - - - - - - - - - ->Ø 80mm - - 50 100 100 100 120 - - 100 50 50 - 100 - - 100 150>Ø 120mm 50 - - - - - - - - - - - - - - - - -Lathe turningα min. 5 6 5 6 6 6 6 6 6 6 6 6 62 2610 10max. 10 10 10 8 8 8 8 8 8 8 8 8 8 5 5γmin. 0 0 0 0 0 0 0 22 0 0 0 0 5 5 0 00max. 5 5 5 5 5 5 5 8 8 5 5 5 5 8 8 5 5min. 45 45 45 45 45 45 45 45 45 45 45 45 45 45 10 10 7 7χmax. 60 60 60 60 60 60 60 60 60 60 60 60 60 6010 10150 250min. 300 250 300 250 250 250 250 150 350 150 250 350 350 350 100 100Vmax. 400 500 400 500 500 500 500 200 400 200 500 40 40 40 500 500 120 120min. 0,2 0,1 0,2 0,1 0,1 0,1 0,1 0,1 0,21 0,1 0,1 0,1 0,1 0,1 0,1 0,1 0,05 0,05smax. 0,4 0,5 0,4 0,5 0,5 0,5 0,5 0,5 0,3 0,3 0,5 0,3 0,3 0,3 0,3 0,3 0,08 0,08Drillingα min. 5 5 5 5 5 5 5 3 6 5 5 5 5 10 10 5 56max. 10 15 10 10 10 10 10 10 6 10 10 10 10 16 16 10 10min. 10 10 10 10 10 10 10 5 10 5 10 10 10 10 5 6 5 5γmax. 20 20 20 30 30 30 30 10 20 10 30 30 30 30 20 20 10 10ϕ 90 90 90 90 90 90 90 120 90 120 90 90 90 90 130 130 120 120VSmin. 50 50 50 50 50 50 50 80 20 80 50 50 50 50 150 150 80 80max. 100 150 100 200 200 200 200 100 80 100 200 20 20 20 200 200 100 100min 0,2 0,1 0,2 0,1 0,1 0,1 0,1 0,1 0,1 0,1 0,1 0,1 0,1 0,1 0,1 0,1 0,02 0,02max. 0,3 0,3 0,3 0,3 0,3 0,3 0,3 0,3 0,3 0,3 0,3 0,3 0,3 0,3 0,3 0,3 0,1 0,1Temperature required during machining[°C]>Ø 60mm - - 80 - - - 120 120 - 100 100 100 - 100 - - - 150>Ø 80mm 80 - 120 120 120 - - - 100 - - - - - - - 150 -MillingαγVmin. 5 10 5 5 5 5 5 15 2 15 5 5 5 5 5 5 2 2max. 15 20 15 15 15 15 15 30 10 30 15 15 15 15 15 15 5 5max. 5 5 5 6 6 6 6 6 1 6 6 6 6 6 5 5 0 0max. 15 15 15 10 10 10 10 10 5 10 10 10 10 10 15 15 5 5min. 250 250 250 250 250 250 250 80 250 80 250 250 250 250 250 250 90 90max. 500 500 500 500 500 500 500 100 500 500 500 500 500 500 500 500 100 100Tools made of tungsten carbide, diamond, ceramicX X X XNo use water-soluble coolants *XX* If the use of cooling emulsions can not be renounced, the workpieces, after machining, should be cleaned with the use of isopropanol and subsequent rinsing with water.α [°] (End) clearance angle χ [°] Toll cutting-edge angle t [mm] Pitch V [m/min] Cutting speedγ [°] (Back) rake angle ϕ [°] Point angle S [mm -1 ] FeedTable 3: machining guideline26 ZEDEX ® basic types ZEDEX ® families Post heattreatmentMachiningShippingoverviewSterilizationChemicalresistance