Semi-finished products Plastic granules Special compounds

Semi-finished products Plastic granules Special compounds

Semi-finished products Plastic granules Special compounds

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

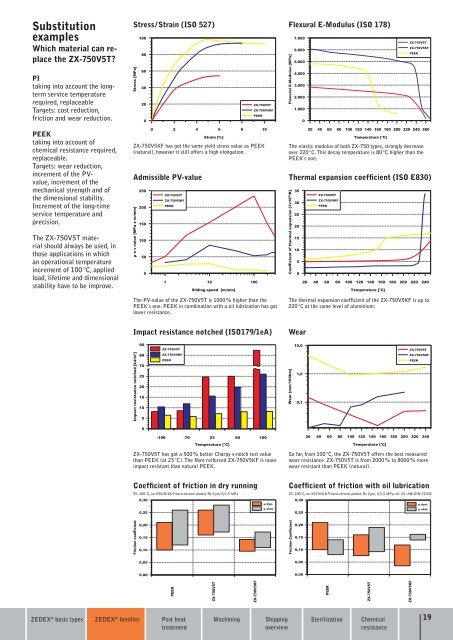

SubstitutionexamplesWhich material can replacethe ZX-750V5T?PItaking into account the longtermservice temperaturerequired, replaceableTargets: cost reduction,friction and wear reduction.Stress / Strain (ISO 527) Flexural E-Modulus (ISO 178)Stress [MPa]10080604020ZX-750V5TZX-750V5KFPEEK0Flexural E-Modulus [MPa]7.0006.0005.0004.0003.0002.0001.0000ZX-750V5TZX-750V5KFPEEKPEEKtaking into account ofchemical resistance required,replaceable.Targets: wear reduction,increment of the PVvalue,increment of themechanical strength and ofthe dimensional stability.Increment of the long-timeservice temperature andprecision.The ZX-750V5T materialshould always be used, inthose applications in whichan operational temperatureincrement of 100 °C, appliedload, lifetime and dimensionalstability have to be improve.0 2 4 6 8 10Strain [%]ZX-750V5KF has got the same yield stress value as PEEK(natural), however it still offers a high elongation.20 40 60 80 100 120 140 160 180 200 220 240 260Temperature [°C]The elastic modulus of both ZX-750 types, strongly decreaseover 220 °C. This decay temperature is 80 °C higher than thePEEK´s one.Admissible PV-value Thermal expansion coefficient (ISO E830)p x v value [MPa x m/min]250200150100500ZX-750V5TZX-750V5KFPEEK1 10 100Sliding speed [m/min]Coefficient of thermal expansion [1x10 -5 /K]35302520151050ZX-750V5TZX-750V5KFPEEK20 40 60 80 100 120 140 160 180 200 220 240Temperature [°C]The PV-value of the ZX-750V5T is 1000 % higher than thePEEK´s one. PEEK in combination with a oil lubrication has gotlower resistance.The thermal expansion coefficient of the ZX-750V5KF is up to220 °C at the same level of aluminium.Impact resistance notched (ISO179/1eA)Wear90ZX-750V5T10,0ZX-750V5TImpact resistance notched [kJ/m²]8070252015105ZX-750V5KFPEEKWear [mm/100km]1,00,1ZX-750V5KFPEEK0-196 -70 23 60 10020 40 60 80 100 120 140 160 180 200 220 240Temperature [°C]Temperature [°C]ZX-750V5T has got a 500 % better Charpy v-notch test valuethan PEEK (at 23 °C). The fibre reiforced ZX-750V5KF is moreimpact resistant than natural PEEK.So far, from 100 °C, the ZX-750V5T offers the best measuredwear resistance. ZX-750V5T is from 2000 % to 8000 % morewear resistant than PEEK (natural).Coefficient of friction in dry running25–100 °C, on X5CrNi18.9 hard-chrome plated, Rz 2 μm, 0,5-5 MPa0,300,25μ dyn.μ stat.Coefficient of friction with oil lubrication25–100 °C, on X5CrNi18.9 hard-chrome plated, Rz 2 μm, 0,5-5 MPa, oil: OL-J46 DIN 515020,30μ dyn.μ stat.0,25Friction coefficient0,200,150,10Friction Coefficient0,200,150,100,050,050,000,00PEEKZX-750V5TZX-750V5KFZX-324/PEEKZX-750V5TZX-750V5KFZEDEX ® basic typesZEDEX ® familiesPost heattreatmentMachiningShippingoverviewSterilizationChemicalresistance19