Semi-finished products Plastic granules Special compounds

Semi-finished products Plastic granules Special compounds

Semi-finished products Plastic granules Special compounds

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

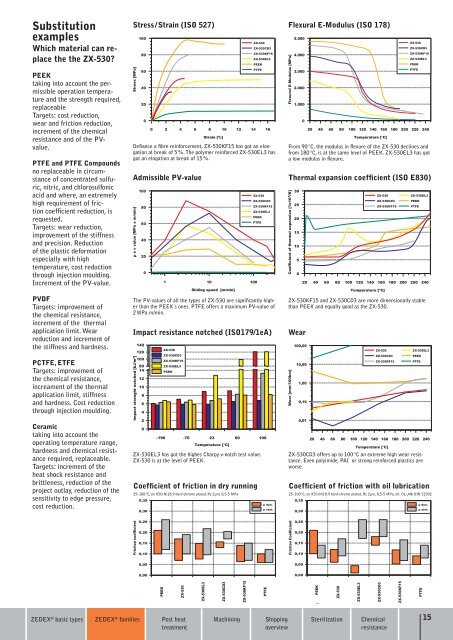

SubstitutionexamplesWhich material can replacethe the ZX-530?PEEKtaking into account the permissibleoperation temperatureand the strength required,replaceableTargets: cost reduction,wear and friction reduction,increment of the chemicalresistance and of the PVvalue.PTFE and PTFE Compoundsno replaceable in circumstanceof concentrated sulfuric,nitric, and chlorosulfonicacid and where, an extremelyhigh requirement of frictioncoefficient reduction, isrequested.Targets: wear reduction,improvement of the stiffnessand precision. Reductionof the plastic deformationespecially with hightemperature, cost reductionthrough injection moulding.Increment of the PV-value.PVDFTargets: improvement ofthe chemical resistance,increment of the thermalapplication limit. Wearreduction and increment ofthe stiffness and hardness.PCTFE, ETFETargets: improvement ofthe chemical resistance,increament of the thermalapplication limit, stiffnessand hardness. Cost reductionthrough injection moulding.Ceramictaking into account theoperating temperature range,hardness and chemical resistancerequired, replaceable.Targets: increment of theheat shock resistance andbrittleness, reduction of theproject outlay, reduction of thesensitivity to edge pressure,cost reduction.Stress / Strain (ISO 527) Flexural E-Modulus (ISO 178)Stress [MPa]1008060402000 2 4 6 8 10 12 14 16Strain [%]Defiance a fibre reinforcement, ZX-530KF15 has got an elongationat break of 5 %. The polymer reinforced ZX-530EL3 hasgot an elogation at break of 15 %.Admissible PV-value Thermal expansion coefficient (ISO E830)p x v value [MPa x m/min]1008060402001 10 100Sliding speed [m/min]The PV-values of all the types of ZX-530 are significantly higherthan the PEEK´s ones. PTFE offers a maximum PV-value of2 MPa m /min.Impact resistance notched (ISO179/1eA)Impact strenght notched [kJ/m²]1401201008014121086420ZX-530ZX-530CD3ZX-530KF15ZX-530EL3PEEKZX-530EL3 has got the highes Charpy v-notch test value.ZX-530 is at the level of PEEK.ZX-530ZX-530CD3ZX-530KF15ZX-530EL3PEEKPTFEZX-530ZX-530CD3ZX-530KF15ZX-530EL3PEEKPTFE-196 -70 23 60 100Temperature [°C]Coefficient of friction in dry running25–100 °C, on X5CrNi18.9 hard-chrome plated, Rz 2 μm, 0,5-5 MPa0,350,30μ dyn.μ stat.Flexural E-Modulus [MPa]5.0004.0003.0002.0001.0000From 90 °C, the modulus in flexure of the ZX-530 declines andfrom 180 °C, is at the same level of PEEK. ZX-530EL3 has gota low modulus in flexure.Coefficient of thermal expansion [1x10 -5 /K]302520151050ZX-530KF15 and ZX-530CD3 are more dimensionally stablethan PEEK and equally good as the ZX-530.WearWear [mm/100km]100,0010,0020 40 60 80 100 120 140 160 180 200 220 240Temperature [°C]ZX-530ZX-530CD3ZX-530KF15ZX-530EL3PEEKPTFE20 40 60 80 100 120 140 160 180 200 220 2401,000,100,01Temperature [°C]ZX-530ZX-530CD3ZX-530KF15ZX-530ZX-530CD3ZX-530KF15ZX-530EL3PEEKPTFE20 40 60 80 100 120 140 160 180 200 220 240Temperature [°C]ZX-530EL3PEEKPTFEZX-530CD3 offers up to 100 °C an extreme high wear resistance.Even polyimide, PAI or strong reinforced plastics areworse.Coefficient of friction with oil lubrication25–100 °C, on X5CrNi18.9 hard-chrome plated, Rz 2 μm, 0,5-5 MPa, oil: OL-J46 DIN 515020,350,30μ dyn.μ stat.Friction coefficient0,250,200,150,100,250,200,150,100,050,050,000,00PEEKZX-530ZX-530EL3ZX-530CD3ZX-530KF15PTFEZX-324/PEEKZX-530ZX-530EL3ZX-530CD3Friction CoefficientZX-530KF15PTFEZEDEX ® basic typesZEDEX ® familiesPost heattreatmentMachiningShippingoverviewSterilizationChemicalresistance15