Semi-finished products Plastic granules Special compounds

Semi-finished products Plastic granules Special compounds

Semi-finished products Plastic granules Special compounds

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

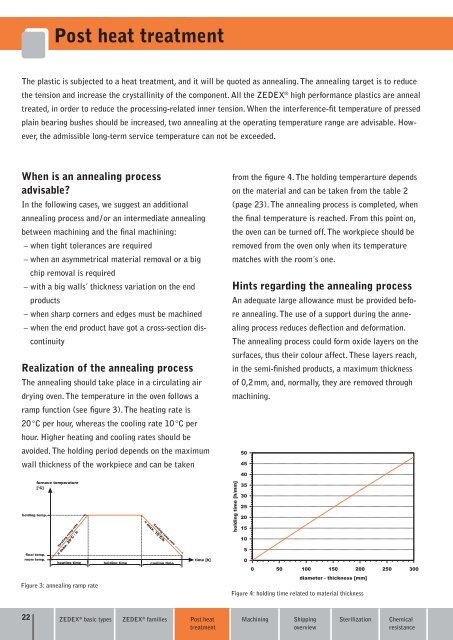

Post heat treatmentThe plastic is subjected to a heat treatment, and it will be quoted as annealing. The annealing target is to reducethe tension and increase the crystallinity of the component. All the ZEDEX ® high performance plastics are annealtreated, in order to reduce the processing-related inner tension. When the interference-fit temperature of pressedplain bearing bushes should be increased, two annealing at the operating temperature range are advisable. However,the admissible long-term service temperature can not be exceeded.When is an annealing processadvisable?In the following cases, we suggest an additionalannealing process and / or an intermediate annealingbetween machining and the final machining:– when tight tolerances are required– when an asymmetrical material removal or a bigchip removal is required– with a big walls´ thickness variation on the end<strong>products</strong>– when sharp corners and edges must be machined– when the end product have got a cross-section discontinuityRealization of the annealing processThe annealing should take place in a circulating airdrying oven. The temperature in the oven follows aramp function (see figure 3). The heating rate is20 °C per hour, whereas the cooling rate 10 °C perhour. Higher heating and cooling rates should beavoided. The holding period depends on the maximumwall thickness of the workpiece and can be takenholding temp.final temp.room temp.furnace temperature[°C]Heating ramp rate= max. 20°C / hCooling ramp rate= max. 10°C/hheating time holding timecooling timeFigure 3: annealing ramp ratetime [h]from the figure 4. The holding temperarture dependson the material and can be taken from the table 2(page 23). The annealing process is completed, whenthe final temperature is reached. From this point on,the oven can be turned off. The workpiece should beremoved from the oven only when its temperaturematches with the room´s one.Hints regarding the annealing processAn adequate large allowance must be provided beforeannealing. The use of a support during the annealingprocess reduces deflection and deformation.The annealing process could form oxide layers on thesurfaces, thus their colour affect. These layers reach,in the semi-<strong>finished</strong> <strong>products</strong>, a maximum thicknessof 0,2 mm, and, normally, they are removed throughmachining.holding time [h/mm]504540353025201510500 50 100 150 200 250 300diameter - thickness [mm]Figure 4: holding time related to material thickness22 ZEDEX ® basic types ZEDEX ® families Post heat Machining ShippingtreatmentoverviewSterilizationChemicalresistance