MIL-HDBK-502 - Barringer and Associates, Inc.

MIL-HDBK-502 - Barringer and Associates, Inc.

MIL-HDBK-502 - Barringer and Associates, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

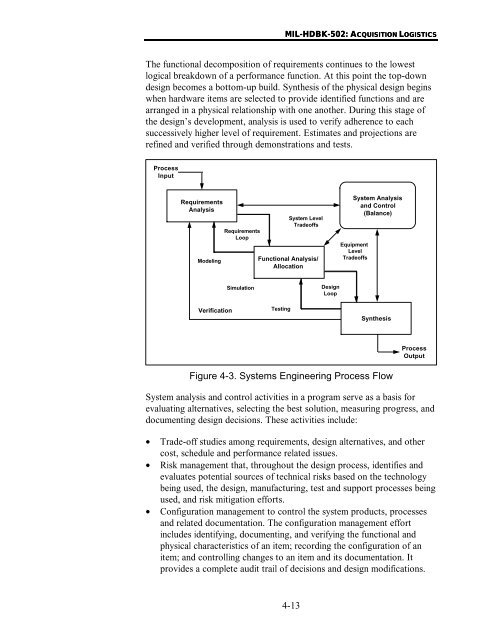

<strong>MIL</strong>-<strong>HDBK</strong>-<strong>502</strong>: ACQUISITIONALOGISTICSThe functional decomposition of requirements continues to the lowestlogical breakdown of a performance function. At this point the top-downdesign becomes a bottom-up build. Synthesis of the physical design beginswhen hardware items are selected to provide identified functions <strong>and</strong> arearranged in a physical relationship with one another. During this stage ofthe design’s development, analysis is used to verify adherence to eachsuccessively higher level of requirement. Estimates <strong>and</strong> projections arerefined <strong>and</strong> verified through demonstrations <strong>and</strong> tests.ProcessInputRequirementsAnalysisModelingRequirementsLoopSystem LevelTradeoffsFunctional Analysis/AllocationSystem Analysis<strong>and</strong> Control(Balance)EquipmentLevelTradeoffsSimulationDesignLoopVerificationTestingSynthesisProcessOutputFigure 4-3. Systems Engineering Process FlowSystem analysis <strong>and</strong> control activities in a program serve as a basis forevaluating alternatives, selecting the best solution, measuring progress, <strong>and</strong>documenting design decisions. These activities include:• Trade-off studies among requirements, design alternatives, <strong>and</strong> othercost, schedule <strong>and</strong> performance related issues.• Risk management that, throughout the design process, identifies <strong>and</strong>evaluates potential sources of technical risks based on the technologybeing used, the design, manufacturing, test <strong>and</strong> support processes beingused, <strong>and</strong> risk mitigation efforts.• Configuration management to control the system products, processes<strong>and</strong> related documentation. The configuration management effortincludes identifying, documenting, <strong>and</strong> verifying the functional <strong>and</strong>physical characteristics of an item; recording the configuration of anitem; <strong>and</strong> controlling changes to an item <strong>and</strong> its documentation. Itprovides a complete audit trail of decisions <strong>and</strong> design modifications.4-13