2010 - Embraco

2010 - Embraco

2010 - Embraco

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

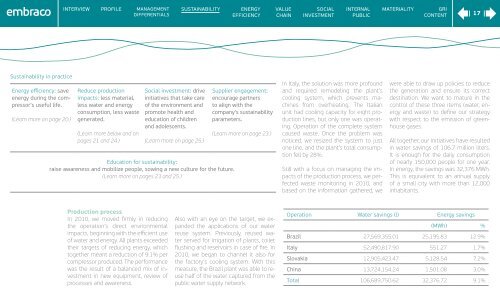

Interview Profile ManagementdifferentialsSustainaBIlityEnergyEffICIencyvalueChaINSoCIalinvestmentInternalPublICMATERIalItyGRIContent17Sustainability in practiceEnergy efficiency: saveenergy during the compressor’suseful life.(Learn more on page 20.)Reduce productionimpacts: less material,less water and energyconsumption, less wastegenerated.(Learn more below and onpages 21 and 24.)Social investment: driveinitiatives that take careof the environment andpromote health andeducation of childrenand adolescents.(Learn more on page 25.)Education for sustainability:raise awareness and mobilize people, sowing a new culture for the future.(Learn more on pages 23 and 25.)Supplier engagement:encourage partnersto align with thecompany's sustainabilityparameters.(Learn more on page 23.)In Italy, the solution was more profoundand required remodeling the plant’scooling system, which prevents machinesfrom overheating. The Italianunit had cooling capacity for eight productionlines, but only one was operating.Operation of the complete systemcaused waste. Once the problem wasnoticed, we resized the system to justone line, and the plant’s total consumptionfell by 28%.Still with a focus on managing the impactsof the production process, we perfectedwaste monitoring in <strong>2010</strong>, andbased on the information gathered, wewere able to draw up policies to reducethe generation and ensure its correctdestination. We want to mature in thecontrol of these three items (water, energyand waste) to define our strategywith respect to the emission of greenhousegases.All together, our initiatives have resultedin water savings of 106.7 million liters.It is enough for the daily consumptionof nearly 150,000 people for one year.In energy, the savings was 32,376 MWh.This is equivalent to an annual supplyof a small city with more than 12,000inhabitants.Production processIn <strong>2010</strong>, we moved firmly in reducingthe operation’s direct environmentalimpacts, beginning with the efficient useof water and energy. All plants exceededtheir targets of reducing energy, whichtogether meant a reduction of 9.1% percompressor produced. The performancewas the result of a balanced mix of investmentin new equipment, review ofprocesses and awareness.Also with an eye on the target, we expandedthe applications of our waterreuse system. Previously, reused waterserved for irrigation of plants, toiletflushing and reservoirs in case of fire. In<strong>2010</strong>, we began to channel it also forthe factory’s cooling system. With thismeasure, the Brazil plant was able to reusehalf of the water captured from thepublic water supply network.Operation Water savings (l) Energy savings(MWh) %Brazil 27,569,355.01 25,195.83 12.9%Italy 52,490,817.90 551.27 1.7%Slovakia 12,905,423.47 5,128.54 7.2%China 13,724,154.24 1,501.08 3.0%Total 106,689,750.62 32,376.72 9.1%