2010 - Embraco

2010 - Embraco

2010 - Embraco

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

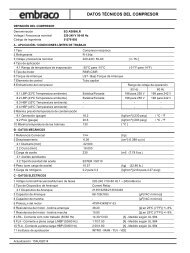

Interview Profile ManagementdifferentialsSustainaBIlityEnergyEffICIencyvalueChaINSoCIalinvestmentInternalPublICMATERIalItyGRIContent21on and off of conventional compressors,variable speed technology resultsin a 35% energy savings with the samecooling capacity.<strong>Embraco</strong> VCC equips the world’s mostefficient refrigerators. In the most demandingmarkets such as Japan, forexample, it represents up to 40% of allequipment sold annually. In <strong>Embraco</strong>,its production has been reinforced.In China, we expanded from 400,000 to800,000 annual production capacity ofthis type of equipment in <strong>2010</strong>, and inMay 2011 we will reach 1.6 million. InBrazil the production line adaptationswill raise annual production capacity of1.6 million to 2.4 million still in 2011.Constant evolutionMaintaining our products’ performanceexcellence is a dynamic process andrequires continuous improvement. Wewant to improve always, and nothingis left out of this quest, even productsthat already stand out with the best results.In the VEM compressor line, forexample, each new generation of com-pressors is more efficient than the previousone. Equipment launched in <strong>2010</strong>consumes 17.34% less energy than thethree previous generations, launched in2003, and the evolution process continues.In 2011, we have already launcheda new generation, reducing consumptionby 4% compared to <strong>2010</strong>.New technologyIn partnership with the New Zealandcompany Fisher & Paykel andthe Whirlpool Corporation, <strong>Embraco</strong>launched a new technology in <strong>2010</strong>with the Linear Oil Free compressor.In addition to combining the most efficientoption in terms of energy consumption(variable speed technology)with a linear and lean design, whichmultiplies the application possibilities,the product also eliminates theuse of lubricating oil for its operation.For the environment the new technologymakes it possible to save non-renewableresources in manufacturingand reduce the risk of contaminationin product disposal. For customers,the main direct advantage is the applicationflexibility: the compressorcan be used in any position inside theequipment.The Linear Oil Free underwent testsin customers in <strong>2010</strong> and in 2011 isalready being manufactured in a pilotproduction line installed in <strong>Embraco</strong>Brazil. In total, the project involvedthe filing of 82 patents. To reach theproduction stage has been the resultof five years of research and an investmentof US$ 20 million.EFFICIENCY w/w1.736%1.837%1.964%2.03Vemy VemZ VemX VemC4%2.11Vemds2003 2006 2008 <strong>2010</strong> 2011