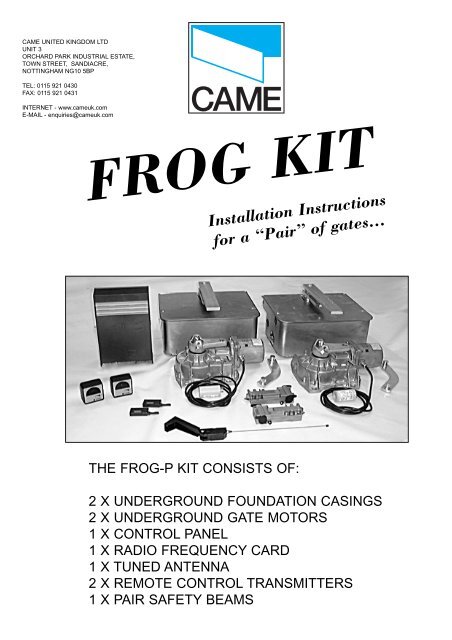

Installation Instructions for a âPairâ of gates...

Installation Instructions for a âPairâ of gates...

Installation Instructions for a âPairâ of gates...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

STAGE 1CIVIL & MECHANICAL SECTION1.1 - <strong>Installation</strong> <strong>of</strong> Foundation CasingsTHE UNDERGROUND CASING SHOULD BE CONCRETED IN THE GROUND. THE CASINGSHOULD HAVE ADEQUATE DRAINAGE TO A SUITABLE SOAK AWAY. WHEN INSTALLING THEFOUNDATION CASING AS A GUIDE ALLOW APPROXIMATELY 100MM AROUND THE CASINGAND 100MM UNDERNEATH THE CASTING FOR CONCRETE.DUCTING FORMOTOR WIRESHEEL OF CASINGSOAK AWAYWHEN CONCRETING THE CASING IN PLACE, ENSURE THAT THE HEEL OF THE CASING ISPACKED WITH CONCRETE AS THIS WHERE ALL OF THE WEIGHT OF THE GATE WILL SIT.ALLOW AT LEAST TWO DAYS FOR THE CONCRETE TO GO OFF.WHEN SETTING THE CASING IN PLACE ENSURE THAT THE TOP HINGE PIN IS PLUMB INLINE WITH THE HINGE PIVOT IN THE CASING. THE CENTRE OF PIVOT IS 65mm STANDOFFFROM THE BACK OF THE CASING. THE CASING SHOULD BE SET PERFECTLY SQUAREAND LEVEL AND PROTRUDING APPROXIMATELY 3MM FROM GROUND LEVEL.WHEN CONCRETING THE CENTRE STOP IN PLACE ENSURE THAT IT DOES NOT PROTRUDEMORE THAN 65mm TO 70mm FROM GROUND LEVEL ANYMORE AND IT MAY DAMAGE THEUNDERSIDE OF LOW VEHICLES.67mm67mm3mm67mm67mm160mm160mm100mm 60mm3mm100mm60mm3

1.2 - Basic Cable LayoutTHIS DIAGRAM DETAILS THE BASIC CABLE LAYOUT FOR A PAIR OF MOTORS.THE POWER SUPPLY TO THE CONTROL PANEL SHOULD BE LIVE AND PROTECTED INACCORDANCE WITH THE 16TH EDITION ELECTRICAL REGULATIONS. THE SUPPLY SHOULDBE RATED AT A MINIMUM OF 6 AMPS. WHEN INSTALLING WIRES OUTDOORS THE CABLEAPPROACH TO ALL DEVICES MUST BE FROM BELOW TO CREATE A “DRIP-LOOP” ANDTHEREBY AVOID UNNECCESSARY WATER INGRESS.CONTROL PANELJOINT BOXJOINT BOXFROG UNDERGROUNDCASING240V A.C.3 CORE SWA 1.5mmMOTOR CABLEIN DUCTING3 CORE SWA 1.5mm1.3 - Low Voltage Cable LayoutTHIS DIAGRAM DETAILS THE BASIC CABLE LAYOUT FOR A PAIR OF MOTORS.THE POWER SUPPLY TO THE CONTROL PANEL SHOULD BE LIVE AND PROTECTED INACCORDANCE WITH THE 16TH EDITION ELECTRICAL REGULATIONS. THE SUPPLY SHOULDBE RATED AT A MINIMUM OF 6 AMPS. WHEN INSTALLING WIRES OUTDOORS THE CABLEAPPROACH TO ALL DEVICES MUST BE FROM BELOW TO CREATE A “DRIP-LOOP” ANDTHEREBY AVOID UNNECCESSARY WATER INGRESS.TUNEDANTENNACOAX CABLEDOC E SAFETYBEAM8 CORE 0.2mm STRANDED TOALL SAFETY BEAMS4

1.4 - Installing the MotorsINSERT THE MOTORS ONTO THE STUDS IN THE CASING. IF THE GATES ARE HUNGBETWEEN THE POSTS AND THE GATES OPEN INWARDS THE MOTORS NEED TO BEPOINTING INTO THE PROPERTY.BACKSTOPCENTRE STOPMOTOR STOPADJUSTERS90° 90°A CENTRE STOP AND BACK STOPS AREALWAYS ADVISED AS WELL AS MOTORADJUSTERSIF THE GATES ARE HUNG ON THE BACK OF THE POSTS THE MOTORS NEED TO BEPOINTING TOWARDS EACH OTHER.1.5 - Hanging the GatesBEFORE ATTACHING THE GATES ENSURE THAT THE GATE PIVOT POINT ARE ADEQUATELYGREASED.WHEN HANGING THE GATE ENSURE THAT THEY ARE SQUARE AND LEVEL BEFOREWELDING THE GATE TO THE FROG SHOE. WHEN WELDING THE GATE TO THE FROG SHOEDO NOT WELD OVER THE THREADED HOLES IN THE SHOE.WHEN HANGING WOODEN GATES IT IS NECCESSARY TO CREATE AU-SHAPED CARRYING SHOE IN MILD STEEL WHICH CAN BE WELDED TO THE TOP SUR-FACE OF THE FROG SHOE. THEN THE WOODEN GATE CAN BE BOLTED INTO POSITIONWITH THE U-SHAPED CARRYING SHOE CLAMPING TO THE BOTTOM OF THE GATE.5

1.6 - Fitting the Gate LockFig. 1Secure the unlocking device to the FROG shoe with the 4 allen bolts provided.Fig. 2UnlockingTo release the gate, raise the protective cap, insert the three sided key and turn it to activate the mechanism.Simultaneously push and/or pull the gate. Remove the key and replace the protective cap.Fig. 3To re-engage the gate, reposition the gate and the mechanism will automatically engage it.6

END OF INSTALLATIONSTAGE 1BEFORE STARTING STAGE 2 - Wiring & ElectricalPLEASE CHECK THAT YOU HAVE CORRECTLY:RefPage1. INSTALLED THE FOUNDATION CASING 1.1 32. PREPARED THE CABLING CORRECTLY 1.2 41.3 43. INSTALLED THE MOTORS CORRECTLY 1.4 54. HUNG THE GATES CORRECTLY 1.5 55. CHECKED THE MANUAL RELEASESYSTEM 1.6 6NOW STAGE 1 IS FULLY COMPLETED YOU ARE READY TOBEGIN STAGE 2 OF YOUR FROG AUTOMATION KITINSTALLATION7

STAGE 2 - WIRING & ELECTRICAL2.1 - Fitting the Control Panel in the CasingSecurely fasten the control panel PCB to the casingwith the screws supplied.Screw positioning holesFastening screwsGreen connector pointScrewsPlug the green connector from the trans<strong>for</strong>mer tothe PCB ensuring that it connects the correct way.NB FROG Series Motors: connect the black wirescoming out <strong>of</strong> the board to one capacitor and thered wires to the other.8

2.2 - Wiring the MotorsTHE FROG MOTORS ALWAYS COME PREWIRED AND THE CONNECTIONS TO THE MOTORSHOULD BE MADE IN THE JUNCTION BOXES AT THE BASE OF THE GATE POST (I.E OUT OFTHE GROUND OR FOUNDATION CASING) AS SHOWN IN FIG 3.UNDER NO CIRCUMSTANCES MUST THE MOTOR BE DISCONNECTED FROM THE GEARBOXAS THIS WILL INVALIDATE THE WARRANTY.WHEN CONNECTING THE MOTORS TO THE CONTROL PANEL THE BLUE WIRE ON THEMOTOR IS THE COMMON WIRE AND IS ALWAYS TO THE “W” ON THE TERMINAL STRIP INTHE CONTROL PANEL. THE BROWN AND BLACK WIRES ARE THE MOTOR DIRECTIONS ANDARE CONNECTED TO “U+V” FOR MOTOR 1 OR “X+Y” FOR MOTOR 2.ENSURE BOTH MOTORS ARE ADEQUATELY EARTHED.MOTOR 1 MOTOR 2U V W W X YMOTOREARTHMOTOREARTHU V W X Y E E39

2.3 - Wiring in the Safety PhotocellsSAFETY BEAMS SHOULD BE FITTED APPROXIMATELY15 INCHES FROM GROUND LEVELCONTROL PANEL10 11 2 C11011TXRXCNC1011SAFETYBEAMTRANSMITTERSAFETYBEAMRECEIVERIF FITTING A SECOND ARC LINE SET OF SAFETY BEAMS THEN C & NC MUSTBE WIRED IN “SERIES”2.4 - Inserting the Radio Frequency CardSAFETY BEAMS SHOULD BE FITTED APPROXIMATELY15 INCHES FROM GROUND LEVELINSERT THE RADIO FREQUENCY CARD INTOTHE SMALL SOCKET ON THE CONTROLPANEL (ENSURE THAT THE POWER ISTURNED OFF TO THE CONTROL PANELBEFOREINSERTING THE FREQUENCY CARD)ZA4ANTENNA WIRINGPOINT10

2.5 - Wiring in the Tuned AntennaANTENNA WIRINGPOINT2.6 - Coding the Remote Controls1. REMOVE THE BATTERY COVER & CASING OF THE REMOTE CONTROL HANDSET TOREVEAL THE DIAGRAM BELOW2. SET THE BANK OFDIPSWITCHES ONALL REMOTES TOEXACTLY THE SAMECODE OF YOURCHOICE.ONOFF7 8 9 10Bat1BattB tON1 2 3 4 5 6 7 8 9 10Battery 12V3. UNLESS PROGRAMMING FORGATES AND GARAGE DOORS TOOPEN BY REMOTE CONTROL FROMTHE SAME HANDSET ENSURETHAT THE JUMPER STRAPS SHOWNHERE ARE IN THE SAME POSITIONSON ALL REMOTES.2.7 - Powering up the Control PanelCONNECT PROTECTED MAINS POWER TO TERMINALS L1 + L2 IN THE CONTROL PANEL (L2BEING LIVE!). ENSURE THAT THE CONTROL PANEL IS ADEQUATELY EARTHED.11

END OF INSTALLATIONSTAGE 2BEFORE STARTING STAGE 3 -Commissioning the Control PanelPLEASE CHECK THAT YOU HAVE CORRECTLY:RefPage1. FITTING THE CONTROL PANELIN THE CASING 2.1 2.1 81. WIRED THE MOTORS AS SHOWN (Fig 7) 2.2 92. WIRED IN THE SAFETY PHOTOCELLSAS SHOWN (Fig 8) 2.3 103. INSERTED THE RADIO FREQUENCYCARD AS SHOWN (Fig 9) 2.4 104. WIRED IN THE TUNED ANTENNACODED AS SHOWN (Fig 10) 2.5 115. PROGRAMMED THE REMOTE CONTROLSAS SHOWN (Fig 11) 2.6 116. POWERED UP THE CONTROL PANEL 2.7 11NOW STAGE 2 IS FULLY COMPLETED YOU ARE READY TOBEGIN STAGE 3 OF YOUR FROG AUTOMATION KITINSTALLATION12

ONOFF1 2 35. SELECT DIPSWITCHES 1 & 2 OFF FORCOMMISSIONING6. ENSURE HARD WIRE LINK IS FITTEDBETWEEN TERMINALS 1 & 2 AND2 & C110 11 S 1 2 3 3P 4 5 7 2 C1 CX B1 B23.2 - Opening & Closing the GatesL1 L2 U V W X Y E1 10 11 1 2 3 5 7 C11. MOMENTARILY PULSE TERMINALS2 & 3 WITH A PIECE OF WIRETRAILING FROM TERMINAL 2 ANDMOMENTARILY TOUCHINGTERMINAL 3.THE GATES SHOULD START TOOPEN. IF THEY START TO CLOSETURN THE POWER OFF TO THECONTROL PANEL AND CHANGEAROUND EITHER U-V (MOTOR 1) ORX-Y (MOTOR 2) TO CHANGETHE MOTOR DIRECTION.L1 L2 U V W X Y E1 10 11 1 2 3 5 7 C12. ONCE YOU HAVE PROVED THEMOTOR DIRECTION USETERMINALS 2 & 7 TO OPEN ANDCLOSE THE GATES WITH ATRAILING WIRE ONCE AGAIN INTOTERMINAL 2, MOMENTARILYTOUCHING TERMINAL 7.14

3.3 - Control Panel Adjustments1. TO DELAY ONE GATE LEAF, ADJUST POTENIOMETER TR2M TO DELAY THE CLOSINOF GATE NO. 2 IN THE CLOSING CYCLE.TRIMMER TR2M2. TO SET THE TOTAL RUNNING TIME OF THE MOTORS, ADJUST POTENIOMETER TL TOALLOW THE MOTORS TO RUN FOR A FURTHER 5-7 SECONDS AFTER THE MOVE-MENT CYCLE HAS BEEN COMPLETED (I.E FULLY OPEN OR FULLY CLOSED).TRIMMER TL3. CHECK THE SENSITIVITY OF THEGATES BY TRYING TO PHYSICALLYSTOP THE GATE AND ADJUST THEPOWER SETTINGS ON THE TRANSFORMER ACCORDINGLY. IF MOREPOWER IS NEEDED FOR HEAVIERGATES THEN SWITCH OFF POWERAND MOVE TRANSFORMER WIRE UPTO SETTING 2. FOR RECHECKINGSENSITIVITY, REPEAT PROCESS UPTO 3 OR 4 IF EVEN MORE POWER ISNEEDED.15

3.4 - Automatic Close & Activating Safety PhotocellsON1OFF 11. TO SELECT AUTOMATIC CLOSING,SELECT DIPSWITCH 2 ON.SET THE AUTOMATIC CLOSING TIME BY ADJUSTING POTENTIOMETER TCATRIMMERTCA6 O’CLOCK POSITIONFULLY ANTI-CLOCKWISE WILL APPROX. AUTOMATICALLY CLOSE THE GATES AFTER 10SECONDS AND FULLY CLOCKWISE WILL APPROX. CLOSE THE GATES AFTER 80 SECONDS.A SENSIBLE SETTING IS ABOUT HALWAY (I.E 6 O’CLOCK POSITION) WHICH WILLAUTOMATICALLY CLOSE THE GATES AFTER APPROX. 30 SECONDS.10 11 1 2 3 5 7 C12. FOR RE-OPENING DURING CLOSING.REMOVE HARD WIRE LINK BETWEEN2 & C1 AND INSERT SAFETY BEAMWIRES AS SHOWN.10 11 C NC16

3.5 - Programming the Remote Controlsto the Control PanelTo use the remote control system, proceed as follows:A) Turn power OFF and insert AF radio frequency board then turn power back onB) Code the transmitter. See the relevant instruction sheet(See Fig 11)C) To store the code on the circuit board Proceed as follows:Press and hold down the programming button on the radio receiver card (the signalLED will start to flash)At the same time transmit on the top button <strong>of</strong> your remote control; keep both the topbutton and the yellow receiver button pressed until the LED stops flashing and remainson constant. It will then go out to indicate that the code has been successfullystored.N.B.If you wish to change the code on your transmitter in the future,simply repeat the procedure above with all the remotes on theinstallation.WARNING:Disconnect the power supply from the control board be<strong>for</strong>e insertingOR removing the AF radio-frquency card from the socket.17

END OF INSTALLATIONSTAGE 3PLEASE CHECK THAT YOU HAVE CORRECTLY:Ref Page1. SET POWER SETTING, INSERTED MOTORCAPACITORS, SET DIPSWITCHES FORCOMMISSIONING, ENSURE WIRE LINKIS FITTED BETWEEN TERMINALS 1 & 2AND 2 & C1 3.1 122. SET THE OPENING AND CLOSING TIMESFOR GATES 3.2 133. ADJUSTED THE CONTROL PANEL 3.3 144. IF REQUIRED, ACTIVATED AUTOMATICCLOSING AND SAFETY PHOTOCELLS 3.4 155. PROGRAMMED THE REMOTE TO THECONTROL PANEL 3.5 1618

4 - TROUBLESHOOTING GUIDEA multimeter will be neededPROBLEMGATE WILL NOT RESPONDWHEN GIVEN A COMMANDSOLUTION1. CHECK POWER SUPPLY TO THECONTROL PANEL.2. CHECK CONTROL PANEL FUSES.3. CHECK HARD WIRE LINK FITTEDBETWEEN TERMINALS 1 & 2.4. CHECK THAT CAPACITORS AREFITTED AND WIRED CORRECTLY.GATES ARE OPEN BUTWILL NOT CLOSE ANDGREEN LED IS FLASHING1. CHECK SAFETY BEAMS ARE WIREDCORRECTLY. (IF MORE THAN ONESET OF BEAMS ARE FITTED THEYMUST BE WIRED IN SERIES.)2. CHECK THAT THERE IS POWERGOING TO THE BEAMS, IF NOTRESTORE POWER.3. IF SAFETY BEAMS ARE NOT FITTEDENSURE THAT A HARD WIRE LINK ISFITTED BETWEEN TERMINALS 2 & C14. REMOVE SAFETY BEAM WIRES 2 &C1 FROM CONTROL PANEL ANDCHECK IF YOU HAVE A NORMALLYCLOSED CIRCUIT COMING FROMTHE BEAMS.WHEN COMMISSIONING GATEAUTOMATICALLY OPENS BUTDOES NOT AUTOMATICALLYCLOSE1. MOTOR WIRES ARE WRONG WAYROUND. CHECK AND PROVE MOTORDIRECTION BY MOMENTORIALLYPULSING TERMINALS 2 & 3. THEGATE SHOULD OPEN UP. TURNAUTOMATIC CLOSING OFF (DIPSWITCH 2) UNTIL MOTORDIRECTION HAS BEEN PROVED.19

PROBLEMGATES WILL NOT RESPOND TOREMOTE CONTROLCOMMANDSOLUTION1. AF FREQUENCY CARD NOT FITTED TOCONTROL PANEL.2. REMOTE CONTROL HAS NOT BEENPROGRAMMED INTO THE CONTROLPANEL.3. REMOTE CONTROL HAS THE WRONGCODE SETTING.4. “OPERATOR PRESENT” HAS NOT BEENSELECTED TO DEACTIVATE RADIOREMOTE CONTROLS (DIPSWITCH 1).5. WRONG FREQUENCY CARD FITTEDFOR THE REMOTE CONTROL.IF THE PROBLEM IS STILL APPARENT CONTACT THE CAMETECHNICAL HELPLINE:0115 921 0430THIS INSTALLATION WAS COMPLETED BY:.........................................................................NAME..............................................................ADDRESS...................................................................................................................................................................................................................................................................................TEL........................ MOBILE............................DATE OF INSTALLATION................................20

GEARMOTORFROG AWEIGHT5 - TECHNICAL INFORMATION5.1 - Technical SpecificationPOWERSUPPLY11 kg 230V a.cCURRENT1,9 APOWER200 WDUTYCYCLEMAX.TORQUE30% * 320 NmREDUCTIONTRAVELTIME1/1152 18 sec.CAPACITOR16 uFFROG AV11 kg230V a.c2,5 A300 W30%* 320 Nm1/11529 sec.20 uF* Can be adjusted using CAME control panelsBOLT FOR REMOVAL &INSERTION OF M6 GREASENIPPLE(NOT SUPPLIED)5.2 - Casting Dimensions60mm160mm405mm330mm5.3 - Operating LimitsWIDTH OF GATE2.00 m2.50 m*3.50 mWEIGHT OF GATE800 Kg600 Kg400 Kg* AN ELECTRIC LOCK IS SUGGESTED WHEN THE GATE WING ISWIDER THAN 3.5M21

5.4 - Motor Torque SettingsSEE ALSO PAGE 14To vary the motor torque, move the indicated spade connector to one <strong>of</strong> the four position: 1=min, 4=max.N.B. It is always best to start from position one and increase the torque setting asrequired.ZA422

5.4 - Motor Torque SettingsDescription <strong>of</strong> Control Panel:Micro-processor controlled electrical cabinet powered by 230V (a/c) at50-60Hz, single phase. Designed <strong>for</strong> control <strong>of</strong> CAME (ATI/FERNI/FROG), <strong>for</strong> hinged<strong>gates</strong>, hinged industrial doors. Designed and built entirely by CAME to meetUNI8612 safety standards at an IP 54 level <strong>of</strong> protection. Housing made <strong>of</strong> ABS isequipped with vents to provide internal air circulation. Guaranteed <strong>for</strong> 3 years, unlesstampered with. This control panel is powered 230V a.c across terminals L1 and L2,and isprotected by a 5A fuse on the main power line. Control systems are powered by lowvoltage and protected by a 2A fuse. The accessories total wattage (24V) must notexceed 20W.Safety:SAFETY BEAMS CAN BE CONNECTED TO OBTAIN:Re-Opening:During closing (2-C1), if the beam is broken while the gate isclosing, they will reverse the direction <strong>of</strong> movement until the gate iscompletely open and will stay open until the obstacle is removed.Total Stop: (1-2) Creates immediate stop <strong>of</strong> gate movement without automaticclosing: (a pushbutton or radio remote control must beactuated to resume movement).N.BIF A NORMALLY CLOSED SAFETY CIRCUIT(2-C1, 1-2) IS OPENED, THE L.E.D WILLFLASH TO INDICATE THE FACT THAT THE BEAM ISBROKEN.Accessories that can be Connected to this Unit:“Gate in Motion” Lamp:The lamp that lights the manoeuvering zone:it remains lit from the the moment the gate begins to open until they are completelyclosed (including the time required <strong>for</strong> the automatic closure).When automatic closure is not enabled, the lamp remains lit only during movement(E-E3).23

Other functions available:Automatic closing:The automatic closing timer is automatically activated at theend <strong>of</strong> the opening cycle. The pre-set, adjustable automaticclosing time is automatically interrupted by the activation <strong>of</strong>any safety system, and is deactivated after a STOPcommand or in case <strong>of</strong> power failure.“Operator present” function:Gate operates only when the pushbutton is held down (theradio control system is deactivated)1 CONTROL PANEL1 FREQUENCY CARD2 UNDERGROUND FOUNDATIONCASINGS WITH PIVOT ARMS.2 UNDERGROUNDGATE MOTORS1 PAIR SAFETY BEAMS2 REMOTE CONTROLTRANSMITTERSTUNED ANTENNA24

5.6 - ZA4 Wiring DiagramTerminals 1 and 2, 2 and C1 are normally closed circuits and ifthey are not used they must be linkedL1 L2 U V W X Y E1 10 11 1 2 3 5 7 C1230V A/CM1Single-Phase motorM2Co-axial cableSingle-Phase motor with leaf delayon closing cycle11 TX10RX1110CNCSafety beams which are connected to obtain Re-openingDuring the closing cycle25

5.7 - Control Panel AdjustmentsTrimmer T.L - Adjustment <strong>of</strong> operating time from a minimum <strong>of</strong> 0 seconds to amaximum <strong>of</strong> 120 seconds N.B. it is advised to let the motors run on <strong>for</strong> between 6and 8 seconds after the last gate has fully close.Trimmer T.C.A - Adjustment <strong>of</strong> automatic closing time from a minimum <strong>of</strong> 1 to amaximum <strong>of</strong> 120 seconds.Trimmer T.R.2.M - Partial opening time adjustment and delay in closing <strong>of</strong> thesecond motor leaf delay from a minimum <strong>of</strong> 0 seconds to a maximum <strong>of</strong> 20 seconds.ZA4T.LT.C.AT.R.M2TRIMMERSADJUSTMENT26

5.8 - Electrical ConnectionsL1 L2 U V W X Y E1 10 11 1 2 3 5 7 C1L1L2UWVXWYWE1105101112Power supply <strong>for</strong> control panelConnection <strong>for</strong> motor one (delay in opening)Connection <strong>for</strong> motor two (delay on closing)230V (A.C) 25W max output in motion (e.g. flashing light)“Gate Open” signal light (24V 3W max)24V (A.C) Output power supply to accessories (max 20W)Stop button (N.C)2327Open only button (N.O)Contact <strong>for</strong> radio and or pushbutton control <strong>for</strong> open-close2C1Contact (N.C) <strong>for</strong> re-opening during closingAntenna connection27

5.9 - Re-Handing the Frog MotorsCENTRE STOPRIGHT90° 90°LEFTON RECEIPT YOUR FROG MOTORS WILL HAVE BEEN SETUP FOR YOU AS APAIR I.E LEFT HAND AND RIGHT HAND BUT SHOULD YOU NEED TO RE-HANDTHESE MOTORS THE FOLLOWING INSTRUCTIONS WILL SHOW YOU HOW.SCREW THE M10 X 100MM BOLT (A) AND THE M10 NUT (B) INTO THEMOTOR TRANSMISSION ARM AS SHOWN IN FIGURE ABOVE. FOR R/HMOTOR INSTALLATION AND FOR L/H MOTOR INSTALLATION SEE FIGUREABOVE.ENSURE THAT THE MOTOR IS CORRECTLY FASTENED INTO THE CASINGWITH THE NUTS AND WASHERS PROVIDED. INSERT THE LIMIT ARM (C)BETWEEN THE MOTOR TRANSMISSION ARM AND THE FROG SHOE. GIVE THEGATE A COMMAND TO OPEN, WHEN THE GATE COMES TO THE OPEN POSI-TION AND THEN ADJUST THE SCREW (A).CLOSE THE GATES SO THAT SCREW (A) MEETS THE LINK ARM. THEN OPENTHE GATE AND ADJUST (A) ACCORDINGLY. DURING ADJUSTMENT ALLOW THEGATE TO PUT ADEQUATE PRESSURE ONTO THE CENTRE STOP BUTALLOWING THE GATE TO BE RE-LOCKED ONTO THE SHOE AFTER MANUALLYRELEASING THE GATE.WHEN ADJUSTMENT IS FINISHED FASTEN NUT (B).28

6. CONTACT INFORMATIONCAME UNITED KINGDOM LTDUNIT 3ORCHARD PARK INDUSTRIAL ESTATETOWN STREET, SANDIACRE, NOTTINGHAM NG10 5BPTEL: 0115 921 0430FAX: 0115 921 0431INTERNET : www.cameuk.comE-MAIL: enquiries@cameuk.comTHIS INSTALLATION WAS COMPLETED BY:.........................................................................NAME..............................................................ADDRESS...................................................................................................................................................................................................................................................................................TEL........................ MOBILE............................DATE OF INSTALLATION................................