6 - Vicat

6 - Vicat

6 - Vicat

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

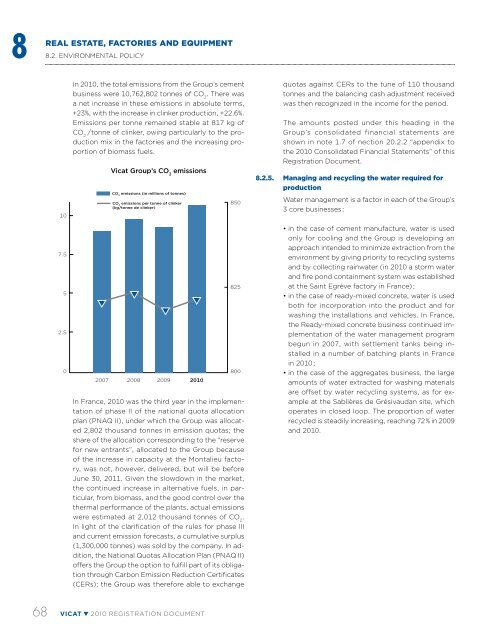

8REAL ESTATE, FACTORIES AND EQUIPMENT8.2. Environmental policy107.552.50In 2010, the total emissions from the Group’s cementbusiness were 10,762,802 tonnes of CO 2. There wasa net increase in these emissions in absolute terms,+23%, with the increase in clinker production, +22.6%.Emissions per tonne remained stable at 817 kg ofCO 2/tonne of clinker, owing particularly to the productionmix in the factories and the increasing proportionof biomass fuels.<strong>Vicat</strong> Group’s CO 2emissionsCO 2 emissions (in millions of tonnes)CO 2 emissions per tonne of clinker(kg/tonne de clinker)2007 2008 2009 2010850825800In France, 2010 was the third year in the implementationof phase II of the national quota allocationplan (PNAQ II), under which the Group was allocated2,802 thousand tonnes in emission quotas; theshare of the allocation corresponding to the “reservefor new entrants”, allocated to the Group becauseof the increase in capacity at the Montalieu factory,was not, however, delivered, but will be beforeJune 30, 2011. Given the slowdown in the market,the continued increase in alternative fuels, in particular,from biomass, and the good control over thethermal performance of the plants, actual emissionswere estimated at 2,012 thousand tonnes of CO 2.In light of the clarification of the rules for phase IIIand current emission forecasts, a cumulative surplus(1,300,000 tonnes) was sold by the company. In addition,the National Quotas Allocation Plan (PNAQ II)offers the Group the option to fulfill part of its obligationthrough Carbon Emission Reduction Certificates(CERs); the Group was therefore able to exchangequotas against CERs to the tune of 110 thousandtonnes and the balancing cash adjustment receivedwas then recognized in the income for the period.The amounts posted under this heading in theGroup’s consolidated financial statements areshown in note 1.7 of nection 20.2.2 “appendix tothe 2010 Consolidated Financial Statements” of thisRegistration Document.8.2.5. Managing and recycling the water required forproductionWater management is a factor in each of the Group’s3 core businesses :• in the case of cement manufacture, water is usedonly for cooling and the Group is developing anapproach intended to minimize extraction from theenvironment by giving priority to recycling systemsand by collecting rainwater (in 2010 a storm waterand fire pond containment system was establishedat the Saint Egrève factory in France) ;• in the case of ready-mixed concrete, water is usedboth for incorporation into the product and forwashing the installations and vehicles. In France,the Ready-mixed concrete business continued implementationof the water management programbegun in 2007, with settlement tanks being installedin a number of batching plants in Francein 2010 ;• in the case of the aggregates business, the largeamounts of water extracted for washing materialsare offset by water recycling systems, as for exampleat the Sablières de Grésivaudan site, whichoperates in closed loop. The proportion of waterrecycled is steadily increasing, reaching 72 % in 2009and 2010.68 VICAT 2010 registration document