You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

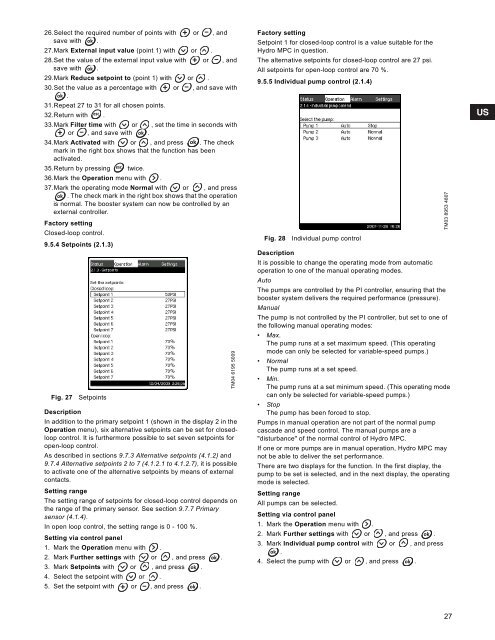

26.Select the required number of points with or , andsave with .27.Mark External input value (point 1) with or .28.Set the value of the external input value with or , andsave with .29.Mark Reduce setpoint to (point 1) with or .30.Set the value as a percentage with or , and save with.31.Repeat 27 to 31 for all chosen points.32.Return with .33.Mark Filter time with or , set the time in seconds withor , and save with .34.Mark Activated with or , and press . The checkmark in the right box shows that the function has beenactivated.35.Return by pressing twice.36.Mark the Operation menu with .37.Mark the operating mode Normal with or , and press. The check mark in the right box shows that the operationis normal. The booster system can now be controlled by anexternal controller.Factory settingClosed-loop control.9.5.4 Setpoints (2.1.3)Fig. 27SetpointsDescriptionIn addition to the primary setpoint 1 (shown in the display 2 in theOperation menu), six alternative setpoints can be set for closedloopcontrol. It is furthermore possible to set seven setpoints foropen-loop control.As described in sections 9.7.3 Alternative setpoints (4.1.2) and9.7.4 Alternative setpoints 2 to 7 (4.1.2.1 to 4.1.2.7), it is possibleto activate one of the alternative setpoints by means of externalcontacts.Setting rangeThe setting range of setpoints for closed-loop control depends onthe range of the primary sensor. See section 9.7.7 Primarysensor (4.1.4).In open loop control, the setting range is 0 - 100 %.Setting via control panel1. Mark the Operation menu with .2. Mark Further settings with or , and press .3. Mark Setpoints with or , and press .4. Select the setpoint with or .5. Set the setpoint with or , and press .TM04 6195 5009Factory settingSetpoint 1 for closed-loop control is a value suitable for the<strong>Hydro</strong> <strong>MPC</strong> in question.The alternative setpoints for closed-loop control are 27 psi.All setpoints for open-loop control are 70 %.9.5.5 Individual pump control (2.1.4)Fig. 28Individual pump controlDescriptionIt is possible to change the operating mode from automaticoperation to one of the manual operating modes.AutoThe pumps are controlled by the PI controller, ensuring that thebooster system delivers the required performance (pressure).ManualThe pump is not controlled by the PI controller, but set to one ofthe following manual operating modes:• Max.The pump runs at a set maximum speed. (This operatingmode can only be selected for variable-speed pumps.)• NormalThe pump runs at a set speed.• Min.The pump runs at a set minimum speed. (This operating modecan only be selected for variable-speed pumps.)• StopThe pump has been forced to stop.Pumps in manual operation are not part of the normal pumpcascade and speed control. The manual pumps are a"disturbance" of the normal control of <strong>Hydro</strong> <strong>MPC</strong>.If one or more pumps are in manual operation, <strong>Hydro</strong> <strong>MPC</strong> maynot be able to deliver the set performance.There are two displays for the function. In the first display, thepump to be set is selected, and in the next display, the operatingmode is selected.Setting rangeAll pumps can be selected.Setting via control panel1. Mark the Operation menu with .2. Mark Further settings with or , and press .3. Mark Individual pump control with or , and press.4. Select the pump with or , and press .TM03 8953 480727