You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

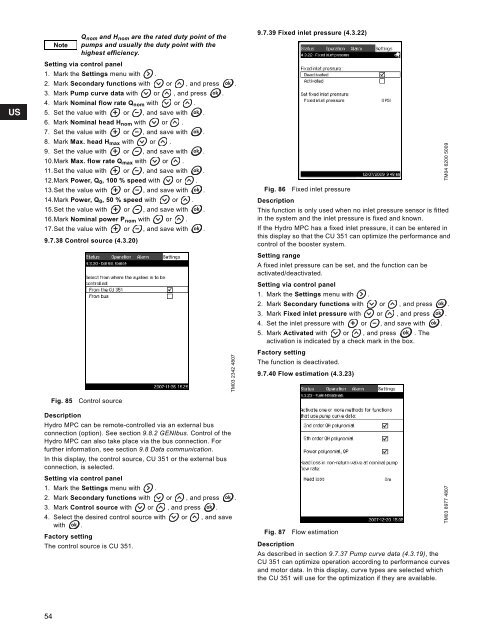

NoteQ nom and H nom are the rated duty point of thepumps and usually the duty point with thehighest efficiency.9.7.39 Fixed inlet pressure (4.3.22)Setting via control panel1. Mark the Settings menu with .2. Mark Secondary functions with or , and press .3. Mark Pump curve data with or , and press .4. Mark Nominal flow rate Q nom with or .5. Set the value with or , and save with .6. Mark Nominal head H nom with or .7. Set the value with or , and save with .8. Mark Max. head H max with or .9. Set the value with or , and save with .10.Mark Max. flow rate Q max with or .11.Set the value with or , and save with .12.Mark Power, Q 0 , 100 % speed with or .13.Set the value with or , and save with .14.Mark Power, Q 0 , 50 % speed with or .15.Set the value with or , and save with .16.Mark Nominal power P nom with or .17.Set the value with or , and save with .9.7.38 Control source (4.3.20)TM03 2342 4807Fig. 86 Fixed inlet pressureDescriptionThis function is only used when no inlet pressure sensor is fittedin the system and the inlet pressure is fixed and known.If the <strong>Hydro</strong> <strong>MPC</strong> has a fixed inlet pressure, it can be entered inthis display so that the CU 351 can optimize the performance andcontrol of the booster system.Setting rangeA fixed inlet pressure can be set, and the function can beactivated/deactivated.Setting via control panel1. Mark the Settings menu with .2. Mark Secondary functions with or , and press .3. Mark Fixed inlet pressure with or , and press .4. Set the inlet pressure with or , and save with .5. Mark Activated with or , and press . Theactivation is indicated by a check mark in the box.Factory settingThe function is deactivated.9.7.40 Flow estimation (4.3.23)TM04 6200 5009Fig. 85Control sourceDescription<strong>Hydro</strong> <strong>MPC</strong> can be remote-controlled via an external busconnection (option). See section 9.8.2 GENIbus. Control of the<strong>Hydro</strong> <strong>MPC</strong> can also take place via the bus connection. Forfurther information, see section 9.8 Data communication.In this display, the control source, CU 351 or the external busconnection, is selected.Setting via control panel1. Mark the Settings menu with .2. Mark Secondary functions with or , and press .3. Mark Control source with or , and press .4. Select the desired control source with or , and savewith .Factory settingThe control source is CU 351.Fig. 87 Flow estimationDescriptionAs described in section 9.7.37 Pump curve data (4.3.19), theCU 351 can optimize operation according to performance curvesand motor data. In this display, curve types are selected whichthe CU 351 will use for the optimization if they are available.TM03 8977 480754