Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

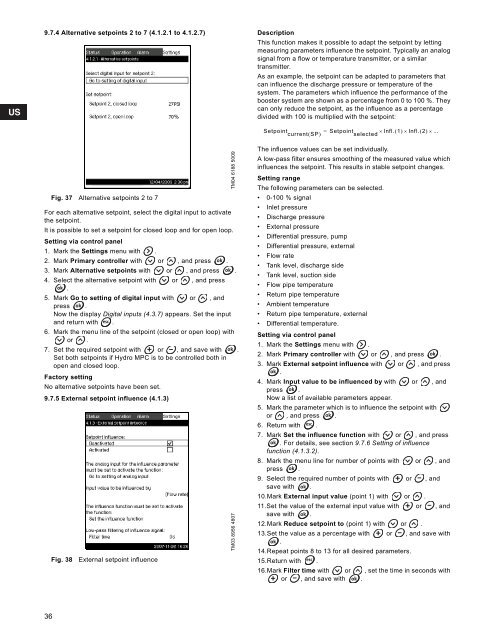

9.7.4 Alternative setpoints 2 to 7 (4.1.2.1 to 4.1.2.7)DescriptionThis function makes it possible to adapt the setpoint by lettingmeasuring parameters influence the setpoint. Typically an analogsignal from a flow or temperature transmitter, or a similartransmitter.As an example, the setpoint can be adapted to parameters thatcan influence the discharge pressure or temperature of thesystem. The parameters which influence the performance of thebooster system are shown as a percentage from 0 to 100 %. Theycan only reduce the setpoint, as the influence as a percentagedivided with 100 is multiplied with the setpoint:Setpoint = Setpoint × Infl. ( 1) × Infl. ( 2) × ...current( SP)selectedFig. 37 Alternative setpoints 2 to 7For each alternative setpoint, select the digital input to activatethe setpoint.It is possible to set a setpoint for closed loop and for open loop.Setting via control panel1. Mark the Settings menu with .2. Mark Primary controller with or , and press .3. Mark Alternative setpoints with or , and press .4. Select the alternative setpoint with or , and press.5. Mark Go to setting of digital input with or , andpress .Now the display Digital inputs (4.3.7) appears. Set the inputand return with .6. Mark the menu line of the setpoint (closed or open loop) withor .7. Set the required setpoint with or , and save with .Set both setpoints if <strong>Hydro</strong> <strong>MPC</strong> is to be controlled both inopen and closed loop.Factory settingNo alternative setpoints have been set.9.7.5 External setpoint influence (4.1.3)Fig. 38External setpoint influenceTM04 6188 5009TM03 8956 4807The influence values can be set individually.A low-pass filter ensures smoothing of the measured value whichinfluences the setpoint. This results in stable setpoint changes.Setting rangeThe following parameters can be selected.• 0-100 % signal• Inlet pressure• Discharge pressure• External pressure• Differential pressure, pump• Differential pressure, external• Flow rate• Tank level, discharge side• Tank level, suction side• Flow pipe temperature• Return pipe temperature• Ambient temperature• Return pipe temperature, external• Differential temperature.Setting via control panel1. Mark the Settings menu with .2. Mark Primary controller with or , and press .3. Mark External setpoint influence with or , and press.4. Mark Input value to be influenced by with or , andpress .Now a list of available parameters appear.5. Mark the parameter which is to influence the setpoint withor , and press .6. Return with .7. Mark Set the influence function with or , and press. For details, see section 9.7.6 Setting of influencefunction (4.1.3.2).8. Mark the menu line for number of points with or , andpress .9. Select the required number of points with or , andsave with .10.Mark External input value (point 1) with or .11.Set the value of the external input value with or , andsave with .12.Mark Reduce setpoint to (point 1) with or .13.Set the value as a percentage with or , and save with.14.Repeat points 8 to 13 for all desired parameters.15.Return with .16.Mark Filter time with or , set the time in seconds withor , and save with .36