Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

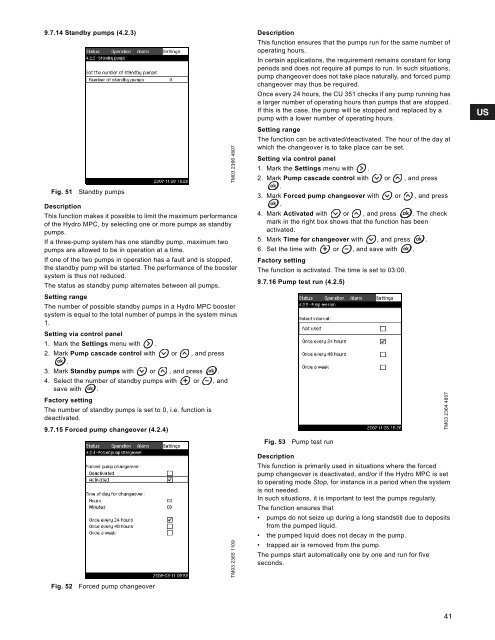

9.7.14 Standby pumps (4.2.3)Fig. 51Standby pumpsDescriptionThis function makes it possible to limit the maximum performanceof the <strong>Hydro</strong> <strong>MPC</strong>, by selecting one or more pumps as standbypumps.If a three-pump system has one standby pump, maximum twopumps are allowed to be in operation at a time.If one of the two pumps in operation has a fault and is stopped,the standby pump will be started. The performance of the boostersystem is thus not reduced.The status as standby pump alternates between all pumps.Setting rangeThe number of possible standby pumps in a <strong>Hydro</strong> <strong>MPC</strong> boostersystem is equal to the total number of pumps in the system minus1.Setting via control panel1. Mark the Settings menu with .2. Mark Pump cascade control with or , and press.3. Mark Standby pumps with or , and press .4. Select the number of standby pumps with or , andsave with .Factory settingThe number of standby pumps is set to 0, i.e. function isdeactivated.9.7.15 Forced pump changeover (4.2.4)TM03 2366 4807DescriptionThis function ensures that the pumps run for the same number ofoperating hours.In certain applications, the requirement remains constant for longperiods and does not require all pumps to run. In such situations,pump changeover does not take place naturally, and forced pumpchangeover may thus be required.Once every 24 hours, the CU 351 checks if any pump running hasa larger number of operating hours than pumps that are stopped.If this is the case, the pump will be stopped and replaced by apump with a lower number of operating hours.Setting rangeThe function can be activated/deactivated. The hour of the day atwhich the changeover is to take place can be set.Setting via control panel1. Mark the Settings menu with .2. Mark Pump cascade control with or , and press.3. Mark Forced pump changeover with or , and press.4. Mark Activated with or , and press . The checkmark in the right box shows that the function has beenactivated.5. Mark Time for changeover with , and press .6. Set the time with or , and save with .Factory settingThe function is activated. The time is set to 03:00.9.7.16 Pump test run (4.2.5)TM03 2364 4807Fig. 53Pump test runTM03 2365 1109DescriptionThis function is primarily used in situations where the forcedpump changeover is deactivated, and/or if the <strong>Hydro</strong> <strong>MPC</strong> is setto operating mode Stop, for instance in a period when the systemis not needed.In such situations, it is important to test the pumps regularly.The function ensures that• pumps do not seize up during a long standstill due to depositsfrom the pumped liquid.• the pumped liquid does not decay in the pump.• trapped air is removed from the pump.The pumps start automatically one by one and run for fiveseconds.Fig. 52Forced pump changeover41