WASTE MANAGEMENT IN LEATHER INDUSTRY

WASTE MANAGEMENT IN LEATHER INDUSTRY

WASTE MANAGEMENT IN LEATHER INDUSTRY

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

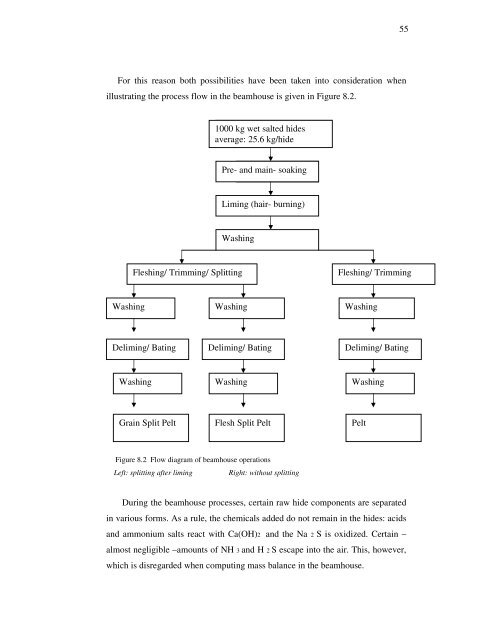

55 68For this reason both possibilities have been taken into consideration whenillustrating the process flow in the beamhouse is given in Figure 8.2.1000 kg wet salted hidesaverage: 25.6 kg/hidePre- and main- soakingLiming (hair- burning)WashingFleshing/ Trimming/ SplittingFleshing/ TrimmingWashingWashingWashingDeliming/ Bating Deliming/ Bating Deliming/ BatingWashing Washing WashingGrain Split Pelt Flesh Split Pelt PeltFigure 8.2 Flow diagram of beamhouse operationsLeft: splitting after limingRight: without splittingDuring the beamhouse processes, certain raw hide components are separatedin various forms. As a rule, the chemicals added do not remain in the hides: acidsand ammonium salts react with Ca(OH)2 and the Na 2 S is oxidized. Certain –almost negligible –amounts of NH 3 and H 2 S escape into the air. This, however,which is disregarded when computing mass balance in the beamhouse.