WASTE MANAGEMENT IN LEATHER INDUSTRY

WASTE MANAGEMENT IN LEATHER INDUSTRY

WASTE MANAGEMENT IN LEATHER INDUSTRY

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

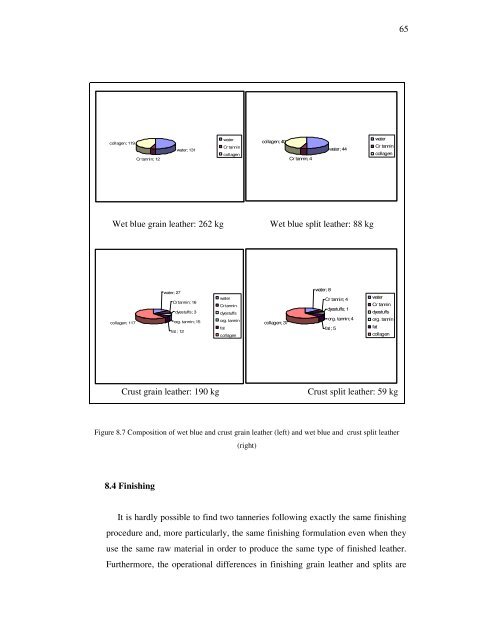

65 78collagen; 119Cr tannin; 12water; 131waterCr tannincollagencollagen; 40Cr tannin; 4water; 44waterCr tannincollagenWet blue grain leather: 262 kgWet blue split leather: 88 kgcollagen; 117water; 27Cr tannin; 16dyestuffs; 3org. tannin; 15fat ; 12waterCr tannindyestuffsorg. tanninfatcollagencollagen; 37water; 8Cr tannin; 4dyestuffs; 1org. tannin; 4fat ; 5waterCr tannindyestuffsorg. tanninfatcollagenCrust grain leather: 190 kgCrust split leather: 59 kgFigure 8.7 Composition of wet blue and crust grain leather (left) and wet blue and crust split leather(right)8.4 FinishingIt is hardly possible to find two tanneries following exactly the same finishingprocedure and, more particularly, the same finishing formulation even when theyuse the same raw material in order to produce the same type of finished leather.Furthermore, the operational differences in finishing grain leather and splits are