WASTE MANAGEMENT IN LEATHER INDUSTRY

WASTE MANAGEMENT IN LEATHER INDUSTRY

WASTE MANAGEMENT IN LEATHER INDUSTRY

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

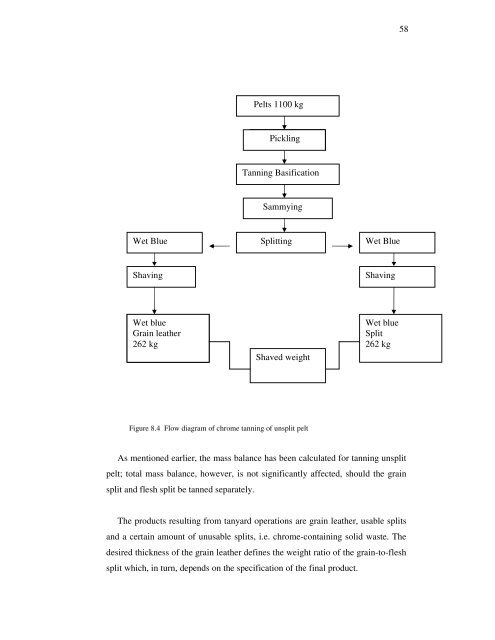

58 71Pelts 1100 kgPicklingTanning BasificationSammyingWet BlueSplittingWet BlueShavingShavingWet blueGrain leather262 kgShaved weightWet blueSplit262 kgFigure 8.4 Flow diagram of chrome tanning of unsplit peltAs mentioned earlier, the mass balance has been calculated for tanning unsplitpelt; total mass balance, however, is not significantly affected, should the grainsplit and flesh split be tanned separately.The products resulting from tanyard operations are grain leather, usable splitsand a certain amount of unusable splits, i.e. chrome-containing solid waste. Thedesired thickness of the grain leather defines the weight ratio of the grain-to-fleshsplit which, in turn, depends on the specification of the final product.