WASTE MANAGEMENT IN LEATHER INDUSTRY

WASTE MANAGEMENT IN LEATHER INDUSTRY

WASTE MANAGEMENT IN LEATHER INDUSTRY

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

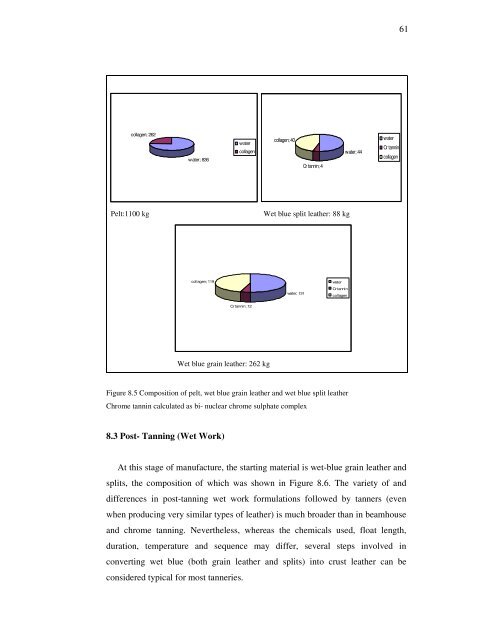

61 74collagen; 262water; 836collagen; 40watercollagen water; 44Cr tannin; 4waterCr tannincollagenPelt:1100 kgWet blue split leather: 88 kgcollagen; 119water; 131waterCr tannincollagenCr tannin; 12Wet blue grain leather: 262 kgFigure 8.5 Composition of pelt, wet blue grain leather and wet blue split leatherChrome tannin calculated as bi- nuclear chrome sulphate complex8.3 Post- Tanning (Wet Work)At this stage of manufacture, the starting material is wet-blue grain leather andsplits, the composition of which was shown in Figure 8.6. The variety of anddifferences in post-tanning wet work formulations followed by tanners (evenwhen producing very similar types of leather) is much broader than in beamhouseand chrome tanning. Nevertheless, whereas the chemicals used, float length,duration, temperature and sequence may differ, several steps involved inconverting wet blue (both grain leather and splits) into crust leather can beconsidered typical for most tanneries.