Pipelaying Tender-VOL II - WorleyParsons.com

Pipelaying Tender-VOL II - WorleyParsons.com

Pipelaying Tender-VOL II - WorleyParsons.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

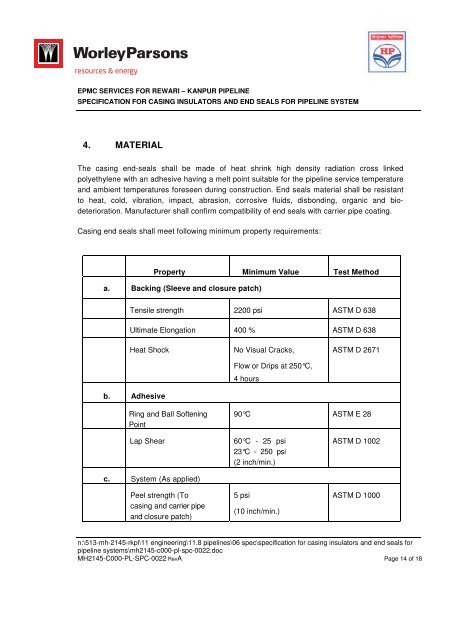

EPMC SERVICES FOR REWARI – KANPUR PIPELINESPECIFICATION FOR CASING INSULATORS AND END SEALS FOR PIPELINE SYSTEM4. MATERIALThe casing end-seals shall be made of heat shrink high density radiation cross linkedpolyethylene with an adhesive having a melt point suitable for the pipeline service temperatureand ambient temperatures foreseen during construction. End seals material shall be resistantto heat, cold, vibration, impact, abrasion, corrosive fluids, disbonding, organic and biodeterioration.Manufacturer shall confirm <strong>com</strong>patibility of end seals with carrier pipe coating.Casing end seals shall meet following minimum property requirements:Property Minimum Value Test Methoda. Backing (Sleeve and closure patch) Tensile strength 2200 psi ASTM D 638 Ultimate Elongation 400 % ASTM D 638 Heat Shock No Visual Cracks,ASTM D 2671Flow or Drips at 250°C,4 hoursb. AdhesiveRing and Ball SofteningPoint90°C ASTM E 28Lap Shear60°C - 25 psi23°C - 250 psi(2 inch/min.)ASTM D 1002c. System (As applied)Peel strength (Tocasing and carrier pipeand closure patch)5 psi(10 inch/min.)ASTM D 1000n:\513-mh-2145-rkpl\11 engineering\11.8 pipelines\06 spec\specification for casing insulators and end seals forpipeline systems\mh2145-c000-pl-spc-0022.docMH2145-C000-PL-SPC-0022 RevA Page 14 of 18