CONTENTS

Contents of 41(2) 2013 - acharya ng ranga agricultural university

Contents of 41(2) 2013 - acharya ng ranga agricultural university

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

INDIAN BREAD MAKING TOOLS - CONSUMER EVALUATION AND DESIGN MODIFICATION<br />

Under subject aspect both the Quantitative<br />

and Qualitative measurements like anthropometry,<br />

palm length, palm width, grip diameter, palm index,<br />

grip strength, elbow angles, time of operation<br />

evaluation of user was done. Six willing respondents<br />

were selected for ergonomic evaluation.<br />

Anthropometry<br />

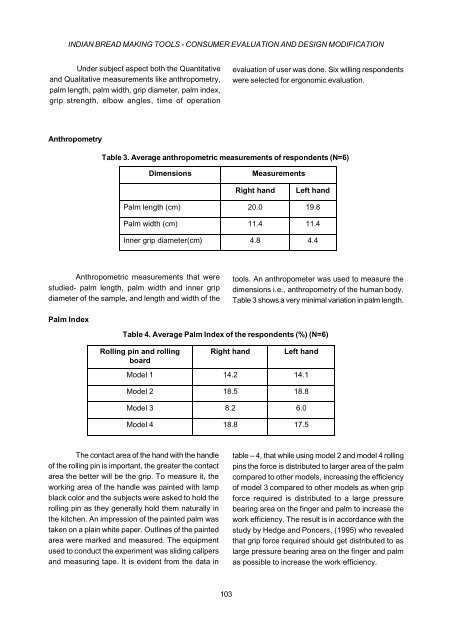

Table 3. Average anthropometric measurements of respondents (N=6)<br />

Dimensions<br />

Measurements<br />

Right hand<br />

Left hand<br />

Palm length (cm) 20.0 19.8<br />

Palm width (cm) 11.4 11.4<br />

Inner grip diameter(cm) 4.8 4.4<br />

Anthropometric measurements that were<br />

studied- palm length, palm width and inner grip<br />

diameter of the sample, and length and width of the<br />

tools. An anthropometer was used to measure the<br />

dimensions i.e., anthropometry of the human body.<br />

Table 3 shows a very minimal variation in palm length.<br />

Palm Index<br />

Table 4. Average Palm Index of the respondents (%) (N=6)<br />

Rolling pin and rolling<br />

board<br />

Right hand<br />

Left hand<br />

Model 1 14.2 14.1<br />

Model 2 18.5 18.8<br />

Model 3 8.2 6.0<br />

Model 4 18.8 17.5<br />

The contact area of the hand with the handle<br />

of the rolling pin is important, the greater the contact<br />

area the better will be the grip. To measure it, the<br />

working area of the handle was painted with lamp<br />

black color and the subjects were asked to hold the<br />

rolling pin as they generally hold them naturally in<br />

the kitchen. An impression of the painted palm was<br />

taken on a plain white paper. Outlines of the painted<br />

area were marked and measured. The equipment<br />

used to conduct the experiment was sliding calipers<br />

and measuring tape. It is evident from the data in<br />

table – 4, that while using model 2 and model 4 rolling<br />

pins the force is distributed to larger area of the palm<br />

compared to other models, increasing the efficiency<br />

of model 3 compared to other models as when grip<br />

force required is distributed to a large pressure<br />

bearing area on the finger and palm to increase the<br />

work efficiency. The result is in accordance with the<br />

study by Hedge and Poncers, (1995) who revealed<br />

that grip force required should get distributed to as<br />

large pressure bearing area on the finger and palm<br />

as possible to increase the work efficiency.<br />

103