Refinery - II M&I SD Oct-Nov 2018

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

`<br />

Chennai Petroleum Corporation Limited (A group company of Indian Oil)<br />

Technical - Inspection<br />

Chennai Petroleum Corporation Limited (A group company of Indian Oil)<br />

Technical - Inspection<br />

2.4.1.46. 15-E-47 A TEMPERED WATER FIN FAN COOLER<br />

No. of tubes Tube dimension Metallurgy Last Retubed Remarks<br />

240 25 mm OD X 3 mm Thk. X 10500 mm A179 Aug-2004 ----<br />

Minor pitting and corrosion was observed on the channel pass partition plate, channel inside & cover.<br />

The tube mouth condition was found satisfactory.<br />

Channel pass partition plate was repaired by weld buildup. Ceramic coating was applied on both tubesheets. Coal<br />

tar epoxy painting was applied to Channel and floating header covers.<br />

Shell Test (KSC) Tube Test (KSC) B. Shell Test (KSC) Old Plugs (nos.) New Plugs (nos.)<br />

Recommendations<br />

--- 18.15 --- 7 0<br />

Anticipate retubing in next M&I shutdown. Anticipate weld repair on Channel<br />

cover and pass partition plate.<br />

2.4.1.47. 15-E-47 B TEMPERED WATER FIN FAN COOLER<br />

No. of tubes Tube dimension Metallurgy Last Retubed Remarks<br />

240 25 mm OD X 3 mm Thk. X 10500 mm A179 Aug-2004 ----<br />

Minor pitting and corrosion observed throughout the channel head partition plate , channel inside & cover.<br />

Severe corrosion was observed on channel partion plate gasket seating surface .<br />

On Channel head to tube sheet weld seam, grooves were observed at random locations.<br />

Tube mouth condition was found satisfactory.<br />

Channel pass partition plate was repaired by weld buildup. Ceramic coating was applied on both tubesheets. Coal<br />

tar epoxy painting was applied to Channel and floating header covers.<br />

Shell Test (KSC) Tube Test (KSC) B. Shell Test (KSC) Old Plugs (nos.) New Plugs (nos.)<br />

Recommendations<br />

--- 18.15 --- 0 0<br />

Anticipate retubing in next M&I shutdown. Anticipate weld repair on Channel cover<br />

and pass partition plate.<br />

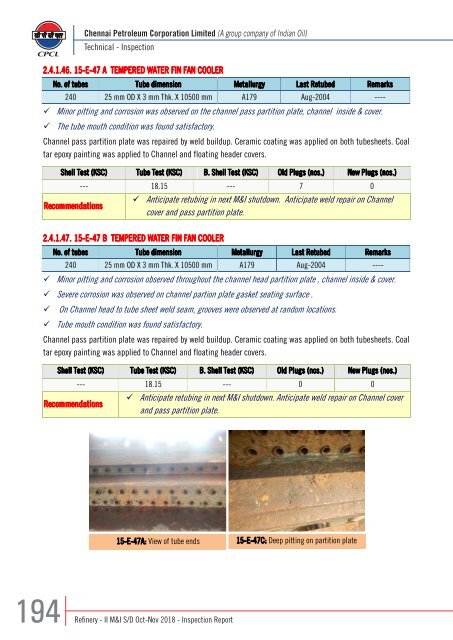

15-E-47A: View of tube ends<br />

15-E-47C: Deep pitting on partition plate<br />

2.4.1.48. 15-E-47 C TEMPERED WATER FIN FAN COOLER<br />

No. of tubes Tube dimension Metallurgy Last Retubed Remarks<br />

240 25 mm OD X 3 mm Thk. X 10500 mm A179 <strong>Nov</strong>-2007 ----<br />

Tube mouth condition was found satisfactory.<br />

Heavy Scalings and pittings were observed on partition plate.<br />

Ceramic coating was found damaged.<br />

Ceramic coating was applied on both tubesheets. Coal tar epoxy painting was applied to Channel and floating<br />

header covers. Partition plate was repaired by weld buildup.<br />

Shell Test (KSC) Tube Test (KSC) B. Shell Test (KSC) Old Plugs (nos.) New Plugs (nos.)<br />

Recommendations<br />

--- 18.15 --- 0 0<br />

Anticipate weld repair on Channel cover and pass partition plate.<br />

2.4.1.49. 15-E-47 D TEMPERED WATER FIN FAN COOLER<br />

No. of tubes Tube dimension Metallurgy Last Retubed Remarks<br />

240 25 mm OD X 3 mm Thk. X 10500 mm A179 <strong>Nov</strong>-2007 ----<br />

Tube mouth condition was found satisfactory.<br />

Heavy Scalings and pittings were observed on partition plate.<br />

Ceramic coating was found damaged.<br />

Ceramic coating was applied on both tubesheets. Coal tar epoxy painting was applied to Channel and floating<br />

header covers. Partition plate was repaired by weld buildup.<br />

Shell Test (KSC) Tube Test (KSC) B. Shell Test (KSC) Old Plugs (nos.) New Plugs (nos.)<br />

Recommendations<br />

--- 18.15 --- 0 0<br />

Anticipate weld repair on Channel cover and pass partition plate.<br />

2.4.1.50. 15-E-47 E TEMPERED WATER FIN FAN COOLER<br />

No. of tubes Tube dimension Metallurgy Last Retubed Remarks<br />

240 25 mm OD X 3 mm Thk. X 10500 mm A179 <strong>Nov</strong>-2007 Retubed<br />

Tube fins were found in damaged condition.<br />

Deep pitting was observed on partition plate.<br />

Deep scaling was observed on tube internals.<br />

During water filling for testing, 2-3 tubes started leaking & during testing many tubes were found leaking.<br />

Completely Retubed. Coal tar epoxy painting was applied to Channel and floating header covers. Channel pass<br />

partition plate was repaired by weld buildup.<br />

Shell Test (KSC) Tube Test (KSC) B. Shell Test (KSC) Old Plugs (nos.) New Plugs (nos.)<br />

Recommendations<br />

--- 18.15 --- 0 0<br />

Anticipate Weld repairs on Channel cover and pass partition plate.<br />

CRUDE DISTILLATION UNIT<br />

(CDU/ VDU-<strong>II</strong> PLANT-15, 17, 18)<br />

194<br />

<strong>Refinery</strong> - <strong>II</strong> M&I S/D <strong>Oct</strong>-<strong>Nov</strong> <strong>2018</strong> - Inspection Report<br />

<strong>Refinery</strong> - <strong>II</strong> M&I S/D <strong>Oct</strong>-<strong>Nov</strong> <strong>2018</strong> - Inspection Report<br />

195