Refinery - II M&I SD Oct-Nov 2018

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Regenerator Air Grid:<br />

Chennai Petroleum Corporation Limited (A group company of Indian Oil)<br />

Technical - Inspection<br />

ARL damage & bulging at few locations on the main header was noticed. ARL on few air grid nozzle tip portion<br />

found damaged/missing. Most of the Air grid nozzle tip found eroded severely up to 10 mm out of projected length<br />

of 80 mm. Tip of almost 70% of air grid nozzles found with mild erosion & most of the air grid nozzle end rings<br />

(2.0 mm thick SS 304) found eroded/missing. As planned earlier, air grid replacement was planned after removal<br />

of old cyclones.<br />

Chennai Petroleum Corporation Limited (A group company of Indian Oil)<br />

Technical - Inspection<br />

Bulges were noticed at several locations on plenum chamber shell plate. Many lug supports found welded on the<br />

plenum shell over a period of time (during each shutdown to hold/rectify cyclones).<br />

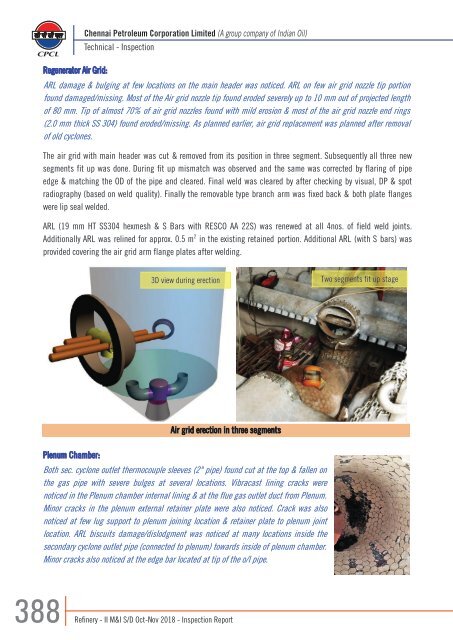

The air grid with main header was cut & removed from its position in three segment. Subsequently all three new<br />

segments fit up was done. During fit up mismatch was observed and the same was corrected by flaring of pipe<br />

edge & matching the OD of the pipe and cleared. Final weld was cleared by after checking by visual, DP & spot<br />

radiography (based on weld quality). Finally the removable type branch arm was fixed back & both plate flanges<br />

were lip seal welded.<br />

ARL (19 mm HT SS304 hexmesh & S Bars with RESCO AA 22S) was renewed at all 4nos. of field weld joints.<br />

Additionally ARL was relined for approx. 0.5 m 2 in the existing retained portion. Additional ARL (with S bars) was<br />

provided covering the air grid arm flange plates after welding.<br />

3D view during erection<br />

Two segments fit up stage<br />

Lug support plates welded on plenum shell<br />

Plenum Chamber:<br />

Air grid erection in three segments<br />

Both sec. cyclone outlet thermocouple sleeves (2" pipe) found cut at the top & fallen on<br />

the gas pipe with severe bulges at several locations. Vibracast lining cracks were<br />

noticed in the Plenum chamber internal lining & at the flue gas outlet duct from Plenum.<br />

Minor cracks in the plenum external retainer plate were also noticed. Crack was also<br />

noticed at few lug support to plenum joining location & retainer plate to plenum joint<br />

location. ARL biscuits damage/dislodgment was noticed at many locations inside the<br />

secondary cyclone outlet pipe (connected to plenum) towards inside of plenum chamber.<br />

Minor cracks also noticed at the edge bar located at tip of the o/l pipe.<br />

Condition of Plenum chamber shell & primary cyclone top flange<br />

Tilting of primary cyclone top flange<br />

towards regen. Cyclone<br />

It was noticed that over a period of last 34 years of service, due to loading (of entire cyclones online &<br />

supporting loads during shutdown maintanance) on plenum chamber skirt plate since inception (1984), both<br />

the primary cyclone flange setup has come inward. Which got reflected in variation of centre to centre distance<br />

between each primary cyclones during verticality verification (same was maintained in order to ensure free<br />

verticality of each cyclone by adjusting the brazing bar length).<br />

Refractory around the takeoff location of the thermocouple sleeves was removed. Old left over portion (damaged<br />

already) was cut & new thermocouple sleeves (2nos) were replaced with 2” Sch 80 SS 304 pipes below the retainer<br />

plate. Refractory around the sleeves was relined (hand packing) after welding few additional anchors. Missing<br />

hexmesh was fixed/welded back at the dislodged location & ARL was relined with RESCO AA 22S. Weld repair was<br />

carried out at the edge bar (tip of the outlet pipe).<br />

FLUIDIZED CATALYTIC<br />

CRACKING UNIT (FCCU – PLANT 16)<br />

388<br />

<strong>Refinery</strong> - <strong>II</strong> M&I S/D <strong>Oct</strong>-<strong>Nov</strong> <strong>2018</strong> - Inspection Report<br />

<strong>Refinery</strong> - <strong>II</strong> M&I S/D <strong>Oct</strong>-<strong>Nov</strong> <strong>2018</strong> - Inspection Report<br />

389