Refinery - II M&I SD Oct-Nov 2018

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Chennai Petroleum Corporation Limited (A group company of Indian Oil)<br />

Technical - Inspection<br />

3.0 FLUIDIZED CATALYTIC CRACKING UNIT- FCCU<br />

3.1 MAJOR OBSERVATIONS & JOBS EXECUTED:<br />

Chennai Petroleum Corporation Limited (A group company of Indian Oil)<br />

Technical - Inspection<br />

Stripper section weld defect at joint no. CS-2 weld joint was repaired (1 spot). Bulged portion IMG & UT was<br />

carried out and found satisfactory.<br />

Following are the highlights of jobs executed during the shutdown.<br />

Decontamination of column, connected piping and process circuits was carried out with oxidizer chemical (0.3-<br />

0.4% oxidizer with DM water) by M/S Spanchem technology, to neutralize pyrophoric iron Sulfide and to remove oil<br />

traces from the surface. After decontamination, columns were handed over to maintenance.<br />

3.1.1 16-F-01<br />

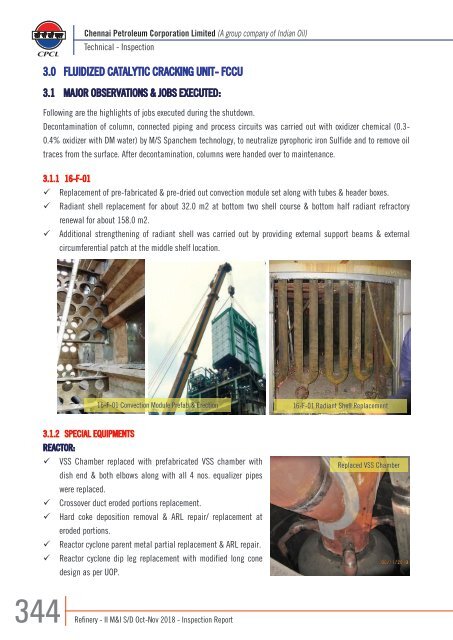

Replacement of pre-fabricated & pre-dried out convection module set along with tubes & header boxes.<br />

Radiant shell replacement for about 32.0 m2 at bottom two shell course & bottom half radiant refractory<br />

renewal for about 158.0 m2.<br />

Additional strengthening of radiant shell was carried out by providing external support beams & external<br />

circumferential patch at the middle shelf location.<br />

RISER:<br />

“Wye” section replacement with a prefabricated “Wye”<br />

Section (from bottom flange @ EL +2100 to EL +5000)<br />

with vibracast lining.<br />

Riser top lid cover replacement with ARL lining on both<br />

sides.<br />

Optimix nozzles (3 Nos.) with barrel were replaced.<br />

Disengaging arm - Eroded portion weld repair & ARL lining<br />

with hexmesh replacement. Disengaging arm guide plates<br />

eroded portion replacement and stopper plate<br />

strengthening.<br />

Cold wall refractory lining repair.<br />

Refractory Lining Repair<br />

REGENERATOR:<br />

Regenerator cyclone (2 pairs – 4 nos.) complete<br />

replacement as 2 segments each<br />

(Main Barrel & Dip leg with middle section)<br />

16-F-01 Convection Module Prefab.& Erection<br />

3.1.2 SPECIAL EQUIPMENTS<br />

REACTOR:<br />

VSS Chamber replaced with prefabricated VSS chamber with<br />

dish end & both elbows along with all 4 nos. equalizer pipes<br />

were replaced.<br />

Crossover duct eroded portions replacement.<br />

Hard coke deposition removal & ARL repair/ replacement at<br />

eroded portions.<br />

Reactor cyclone parent metal partial replacement & ARL repair.<br />

Reactor cyclone dip leg replacement with modified long cone<br />

16-F-01 Radiant Shell Replacement<br />

Replaced VSS Chamber<br />

Air grid complete replacement (3 Segments).<br />

Ski Jump location cover plate replacement.<br />

Big manway cover & flange in-situ machining<br />

Internal castable refractory relining for about 20.0<br />

m 2 .<br />

STANDPIPE & SLIDE VALVES:<br />

RCSP internal refractory repair using Sure flow 17E.<br />

Slide valve servicing & spare part replacement in all slide valves<br />

CO Main duct replacement with internal ARL.<br />

Replaced Regen. Cyclones<br />

CO By-pass duct bulged portion replacement & crack location weld repair and DP test.<br />

COB inlet & outlet Zero Leak Guillotine Valves (ZLGV) seal & retainer ring replacement and refractory lining<br />

repair.<br />

16-EB-03: Flue Gas Line Expansion Bellow replacement.<br />

MAB suction filter house complete replacement with in-house fabrication. MAB suction hood silencer<br />

repaired.<br />

FLUIDIZED CATALYTIC<br />

CRACKING UNIT (FCCU – PLANT 16)<br />

design as per UOP.<br />

344<br />

<strong>Refinery</strong> - <strong>II</strong> M&I S/D <strong>Oct</strong>-<strong>Nov</strong> <strong>2018</strong> - Inspection Report<br />

<strong>Refinery</strong> - <strong>II</strong> M&I S/D <strong>Oct</strong>-<strong>Nov</strong> <strong>2018</strong> - Inspection Report<br />

345