Refinery - II M&I SD Oct-Nov 2018

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Minor pitting throughout the internal surface was noticed.<br />

Weld build up at deeply pitted area was carried out. Thickness gauging was done and a minimum thickness of 8.0<br />

mm & 10.1 mm was recorded against the original thickness of 8.0 mm & 10.0 mm on shell & dished end<br />

respectively.<br />

Recommendations<br />

Anticipate weld repair on shell pitted locations.<br />

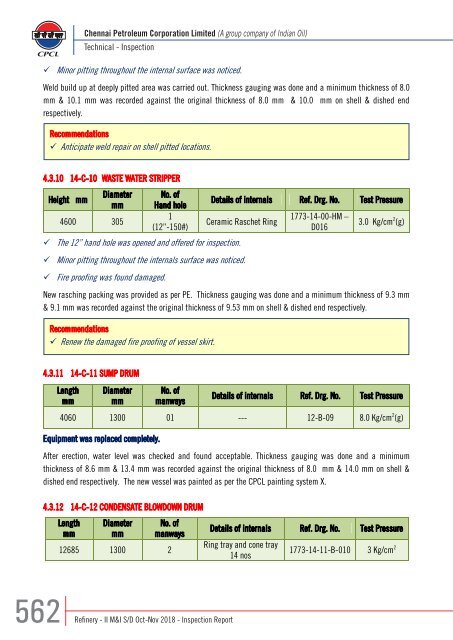

4.3.10 14-C-10 WASTE WATER STRIPPER<br />

Height mm<br />

Diameter<br />

mm<br />

4600 305<br />

The 12” hand hole was opened and offered for inspection.<br />

Minor pitting throughout the internals surface was noticed.<br />

Fire proofing was found damaged.<br />

New rasching packing was provided as per PE. Thickness gauging was done and a minimum thickness of 9.3 mm<br />

& 9.1 mm was recorded against the original thickness of 9.53 mm on shell & dished end respectively.<br />

Recommendations<br />

Renew the damaged fire proofing of vessel skirt.<br />

4.3.11 14-C-11 SUMP DRUM<br />

Length<br />

mm<br />

Diameter<br />

mm<br />

Equipment was replaced completely.<br />

No. of<br />

Hand hole<br />

1<br />

(12”-150#)<br />

No. of<br />

manways<br />

After erection, water level was checked and found acceptable. Thickness gauging was done and a minimum<br />

thickness of 8.6 mm & 13.4 mm was recorded against the original thickness of 8.0 mm & 14.0 mm on shell &<br />

dished end respectively. The new vessel was painted as per the CPCL painting system X.<br />

4.3.12 14-C-12 CONDENSATE BLOWDOWN DRUM<br />

Details of internals Ref. Drg. No. Test Pressure<br />

Ceramic Raschet Ring<br />

1773-14-00-HM –<br />

D016<br />

3.0 Kg/cm 2 (g)<br />

Details of internals Ref. Drg. No. Test Pressure<br />

4060 1300 01 --- 12-B-09 8.0 Kg/cm 2 (g)<br />

Length<br />

mm<br />

Chennai Petroleum Corporation Limited (A group company of Indian Oil)<br />

Technical - Inspection<br />

Diameter<br />

mm<br />

No. of<br />

manways<br />

12685 1300 2<br />

Details of internals Ref. Drg. No. Test Pressure<br />

Ring tray and cone tray<br />

14 nos<br />

1773-14-11-B-010 3 Kg/cm 2<br />

Equipment was replaced completely.<br />

Weld build up was carried on foundation bolts at corrode<br />

locations. After erection water level was checked and found<br />

acceptable.<br />

Level gauge stand pipe (2”) and bottom drain pipeline (6”)<br />

were replaced. Newly fabricated monkey ladder was replaced.<br />

14-C-12: Anchor Bolt Weld Repair & DPT<br />

Recommendations<br />

Skirt fire proofing of vessel shall be done in the next available opporutunity.<br />

Modification may be made in internal arrangement of donut trays and disc trays for easy dismantling and<br />

removal.<br />

<br />

4.3.13 14-C-13 MIBK STORAGE TANK<br />

Length<br />

mm<br />

Diameter<br />

mm<br />

No. of<br />

Manways<br />

The MIBK storage tank was not released for M&I shutdown as in the last M&I, Since used solvent was stored.<br />

Tank thickness gauging was done and a minimum thickness of 7.5 mm was observed against original thickness of<br />

8.0 mm.<br />

Recommendations<br />

Tank shall be released online for internal inspection & Maintenance.<br />

4.3.14 14-C-14 SLOP AND FOOTS OIL MIX TANK<br />

Details of internals Ref. Drg. No. Test Pressure<br />

4880 3050 1 ----- C-157 -----<br />

Height<br />

mm<br />

Diameter<br />

mm<br />

Chennai Petroleum Corporation Limited (A group company of Indian Oil)<br />

No. of<br />

Manways<br />

Technical - Inspection<br />

Details of internals Ref. Drg. No. Test Pressure<br />

880 3005 1 (18” -150#) ----- C-158 Water fill test<br />

Tank was taken for internal inspection & maintenance as a part of pre-shutdown activity. Tank shell and roof<br />

manways were opened and sludge was removed manually.<br />

On initial inspection, the tank shell, bottom plate and roof plate underside were found with thick corrosion<br />

scale.<br />

After cleaning, the shell plate at bottom course was found to have low thickness and also severe pitting corrosion<br />

was observed all over the shell course plate, bottom plate and roof plate.<br />

WAX DEOILING UNIT &<br />

HYDROFINISHING UNIT<br />

562<br />

<strong>Refinery</strong> - <strong>II</strong> M&I S/D <strong>Oct</strong>-<strong>Nov</strong> <strong>2018</strong> - Inspection Report<br />

<strong>Refinery</strong> - <strong>II</strong> M&I S/D <strong>Oct</strong>-<strong>Nov</strong> <strong>2018</strong> - Inspection Report<br />

563