Refinery - II M&I SD Oct-Nov 2018

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Chennai Petroleum Corporation Limited (A group company of Indian Oil)<br />

Technical - Inspection<br />

Chennai Petroleum Corporation Limited (A group company of Indian Oil)<br />

Technical - Inspection<br />

machineries & a meticulous plan. The anticipated job scope in R-R circuit was found to be almost in line with<br />

requirement after equipment opening and considerable replacement of heater tubes were reduced from the<br />

planned scope of work. It appears that the scheduled no. of engg. days (28 days) as per standard guidelines were<br />

are not reviewed further in line with the extensive scope of work planned this time, especially when multiple<br />

agencies had to perform with heavy machineries around R-R circuit & CO Boiler. It was felt that the no. of days<br />

scheduled is not practical enough to complete the scope of work in critical equipments.<br />

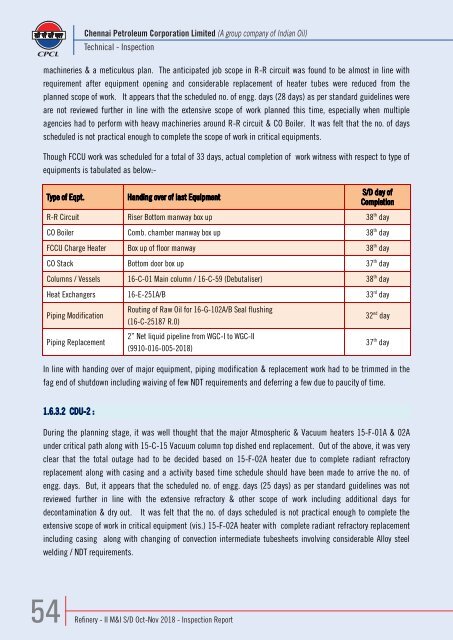

Though FCCU work was scheduled for a total of 33 days, actual completion of work witness with respect to type of<br />

equipments is tabulated as below:-<br />

Type of Eqpt.<br />

Handing over of last Equipment<br />

S/D day of<br />

Completion<br />

R-R Circuit Riser Bottom manway box up 38 th day<br />

CO Boiler Comb. chamber manway box up 38 th day<br />

FCCU Charge Heater Box up of floor manway 38 th day<br />

Though CDU-2 work was scheduled for a total of 30 days, actual completion of work witnessed with respect to<br />

type of equipments is tabulated as below:-<br />

Type of Eqpt.<br />

Handing over of last equipment<br />

S/D day of<br />

Completion<br />

15-F-01A Manway boxup 35 th day<br />

15-F-01B Manway boxup 36 th day<br />

15-F-02A Manway boxup 36 th day<br />

15-F-02B Manway boxup 36 th day<br />

Columns / Vessels 15-C-05 (Kero Stripper) boxup 37 th day<br />

Heat Exchangers 15-E-111A/B 38 th day<br />

Piping Modification 2” velocity line provision in 15-F-02B 39 th day<br />

Piping Replacement<br />

2” stabiliser naphtha from 15-E-18A/B shell O/l to FCC riser<br />

(2”-P-15-4215-A1A)<br />

41 st day<br />

INSPECTION EXECUTIVE SUMMARY<br />

CO Stack Bottom door box up 37 th day<br />

Columns / Vessels 16-C-01 Main column / 16-C-59 (Debutaliser) 38 th day<br />

Heat Exchangers 16-E-251A/B 33 rd day<br />

Piping Modification<br />

Piping Replacement<br />

Routing of Raw Oil for 16-G-102A/B Seal flushing<br />

(16-C-25187 R.0)<br />

2” Net liquid pipeline from WGC-I to WGC-<strong>II</strong><br />

(9910-016-005-<strong>2018</strong>)<br />

32 nd day<br />

37 th day<br />

In line with handing over of major equipment, piping modification & replacement work had to be trimmed in the<br />

fag end of shutdown including waiving of few NDT requirements and deferring a few due to paucity of time.<br />

1.6.3.2 CDU-2 :<br />

During the planning stage, it was well thought that the major Atmospheric & Vacuum heaters 15-F-01A & 02A<br />

under critical path along with 15-C-15 Vacuum column top dished end replacement. Out of the above, it was very<br />

clear that the total outage had to be decided based on 15-F-02A heater due to complete radiant refractory<br />

replacement along with casing and a activity based time schedule should have been made to arrive the no. of<br />

engg. days. But, it appears that the scheduled no. of engg. days (25 days) as per standard guidelines was not<br />

reviewed further in line with the extensive refractory & other scope of work including additional days for<br />

decontamination & dry out. It was felt that the no. of days scheduled is not practical enough to complete the<br />

extensive scope of work in critical equipment (vis.) 15-F-02A heater with complete radiant refractory replacement<br />

including casing along with changing of convection intermediate tubesheets involving considerable Alloy steel<br />

welding / NDT requirements.<br />

In line with handing over of major equipment, piping modification & replacement work had to be trimmed in the<br />

fag end of shutdown including waiving of few NDT requirements and deferring a few due to paucity of time.<br />

1.6.3.3 Wax & Propylene :<br />

There was no major critical works planned in Wax & Propylene units other than routine maintenance work and<br />

anticipated repairs / replacement. Both the units were scheduled for a total of 30 days, but the actual completion<br />

of work witnessed with respect to type of equipments is tabulated as below:-<br />

Type of Eqpt.<br />

Handing over of last Equipment<br />

S/D day of<br />

Completion<br />

14-F-01 Manway boxup 35 th day<br />

14-F-101 Manway boxup 20 th day<br />

Columns / Vessels<br />

Heat Exchangers<br />

Piping Modification<br />

Piping Replacement<br />

14-C-15 (Inert gas holder)<br />

19-C-01<br />

14-E-65A/B/C (R22 Condenser)<br />

19-E-02A /04<br />

Mass flow meter for FO Supply & Return line in 14-F-01(14-D-25317<br />

R.1)<br />

19-E-05 tube side I/L & O/L-BV Provision for isolation purpose & PT<br />

provision for monitoring (19-C-25457)<br />

14-T-1hot solvent gut wash 2” (9910-014-008-2016)<br />

17 th day<br />

40 th day<br />

35 th day<br />

36 th day<br />

32 nd day<br />

36 th day<br />

33 rd day<br />

2” FG header take off to 19-C-5 (9910-019-004-<strong>2018</strong>) 35 th day<br />

In line with handing over of major equipment, piping modification & replacement work had to be trimmed in the<br />

fag end of shutdown including waiving of few NDT requirements and deferring a few due to paucity of time.<br />

54<br />

<strong>Refinery</strong> - <strong>II</strong> M&I S/D <strong>Oct</strong>-<strong>Nov</strong> <strong>2018</strong> - Inspection Report<br />

<strong>Refinery</strong> - <strong>II</strong> M&I S/D <strong>Oct</strong>-<strong>Nov</strong> <strong>2018</strong> - Inspection Report<br />

55