Refinery - II M&I SD Oct-Nov 2018

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Chennai Petroleum Corporation Limited (A group company of Indian Oil)<br />

Chennai Petroleum Corporation Limited (A group company of Indian Oil)<br />

Technical - Inspection<br />

Technical - Inspection<br />

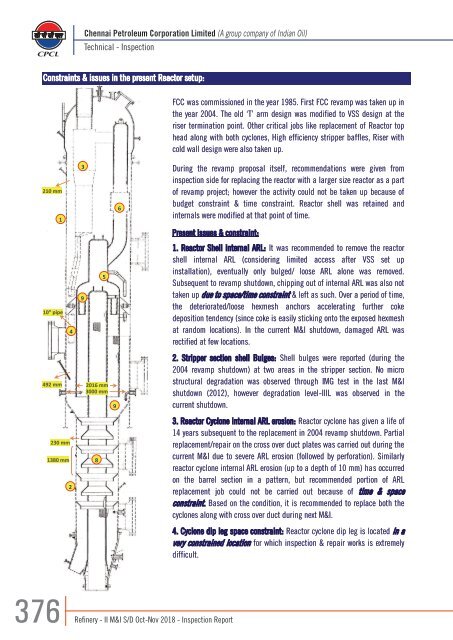

Constraints & issues in the present Reactor setup:<br />

210 mm<br />

1<br />

10” pipe<br />

492 mm<br />

230 mm<br />

1380 mm<br />

4<br />

2<br />

3<br />

9<br />

2016 mm<br />

3000 mm<br />

8<br />

5<br />

9<br />

6<br />

FCC was commissioned in the year 1985. First FCC rev<strong>amp</strong> was taken up in<br />

the year 2004. The old ‘T’ arm design was modified to VSS design at the<br />

riser termination point. Other critical jobs like replacement of Reactor top<br />

head along with both cyclones, High efficiency stripper baffles, Riser with<br />

cold wall design were also taken up.<br />

During the rev<strong>amp</strong> proposal itself, recommendations were given from<br />

inspection side for replacing the reactor with a larger size reactor as a part<br />

of rev<strong>amp</strong> project; however the activity could not be taken up because of<br />

budget constraint & time constraint. Reactor shell was retained and<br />

internals were modified at that point of time.<br />

Present Issues & constraint:<br />

1. Reactor Shell internal ARL: It was recommended to remove the reactor<br />

shell internal ARL (considering limited access after VSS set up<br />

installation), eventually only bulged/ loose ARL alone was removed.<br />

Subsequent to rev<strong>amp</strong> shutdown, chipping out of internal ARL was also not<br />

taken up due to space/time constraint & left as such. Over a period of time,<br />

the deteriorated/loose hexmesh anchors accelerating further coke<br />

deposition tendency (since coke is easily sticking onto the exposed hexmesh<br />

at random locations). In the current M&I shutdown, damaged ARL was<br />

rectified at few locations.<br />

2. Stripper section shell Bulges: Shell bulges were reported (during the<br />

2004 rev<strong>amp</strong> shutdown) at two areas in the stripper section. No micro<br />

structural degradation was observed through IMG test in the last M&I<br />

shutdown (2012), however degradation level-<strong>II</strong>IL was observed in the<br />

current shutdown.<br />

3. Reactor Cyclone internal ARL erosion: Reactor cyclone has given a life of<br />

14 years subsequent to the replacement in 2004 rev<strong>amp</strong> shutdown. Partial<br />

replacement/repair on the cross over duct plates was carried out during the<br />

current M&I due to severe ARL erosion (followed by perforation). Similarly<br />

reactor cyclone internal ARL erosion (up to a depth of 10 mm) has occurred<br />

on the barrel section in a pattern, but recommended portion of ARL<br />

replacement job could not be carried out because of time & space<br />

constraint. Based on the condition, it is recommended to replace both the<br />

cyclones along with cross over duct during next M&I.<br />

4. Cyclone dip leg space constraint: Reactor cyclone dip leg is located in a<br />

very constrained location for which inspection & repair works is extremely<br />

difficult.<br />

7<br />

5. VSS Chamber & transfer pipe internal erosion: Frequent erosion pattern<br />

has been observed in the VSS chamber to transfer pipe joining location &<br />

transfer pipe elbows. Same is being replaced in a frequent interval (all M&I<br />

shutdowns).<br />

6. Expansion bellow inspection constraint: Similarly transfer pipe (Riser-<br />

Reactor termination) expansion bellow is also located in a space constraint<br />

location. Complete health assessment of the subject bellow could not be<br />

carried out in the M&I shutdowns.<br />

7. Riser: Riser internal refractory damage was noticed at many locations in<br />

the form of vertical grooves for a depth up to 2” against the original<br />

refractory thickness of 5” (with many exposed anchors). It was<br />

recommended for refractory relining for about 8.0 m 2 . However it was<br />

extremely difficult to break the refractory lining in such space constrained<br />

location. Breaking & relining of refractory was done only for about 3.0 m 2 in<br />

15-20 days.<br />

8. Stripper baffle cleaning & inspection issue: Stripper baffles were<br />

replaced with high efficiency type in the 2004 rev<strong>amp</strong> shutdown. However<br />

with space constraint & inaccessible location, it has become extremely<br />

difficult to clear the chocked (plugged with hard coke deposits) baffle holes<br />

in the subsequent shutdowns. Cleaning & inspection was done only from<br />

accessible locations (near both manway) & from top/bottom.<br />

9. Internal chamber assessment: Space<br />

constraint is also being faced while<br />

approaching the gap between the riser &<br />

internal chamber. Similarly, the disengaging<br />

arm support locations are also located in a<br />

very constrained location. The locations are<br />

very difficult not only for inspection, but also<br />

a time consuming process in case of<br />

repair/replacement.<br />

The above observations & key points were noted during the<br />

current M&I shutdown.<br />

Recommendations are furnished along with the<br />

recommendation summary.<br />

492 mm<br />

4<br />

9<br />

FLUIDIZED CATALYTIC<br />

CRACKING UNIT (FCCU – PLANT 16)<br />

376<br />

<strong>Refinery</strong> - <strong>II</strong> M&I S/D <strong>Oct</strong>-<strong>Nov</strong> <strong>2018</strong> - Inspection Report<br />

<strong>Refinery</strong> - <strong>II</strong> M&I S/D <strong>Oct</strong>-<strong>Nov</strong> <strong>2018</strong> - Inspection Report<br />

377