D10: Impact of Contaminants - Hydromod

D10: Impact of Contaminants - Hydromod

D10: Impact of Contaminants - Hydromod

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Integrated Water Resource Management for Important Deep European Lakes and their Catchment Areas<br />

EUROLAKES<br />

<strong>D10</strong>: <strong>Impact</strong> <strong>of</strong> <strong>Contaminants</strong><br />

FP5_Contract No.: EVK1-CT1999-00004<br />

Version: 4.0<br />

Date: 25/07/01<br />

File: <strong>D10</strong>-vers.4.0.doc<br />

Page 96 <strong>of</strong> 136<br />

Anaerobic digestion<br />

In an anaerobic digester the organic material is metabolised into approx. 2 /3 CH4, 1 /3<br />

CO2 and biomass. The process is performed in a stirred reactor at a temperature between<br />

30-37 °C. The gas can be used for heating or energy generation. After anaerobic<br />

digestion the stabilised sludge is thickened to the extent required for the final disposal.<br />

Aerobic stabilisation<br />

Excess sludge can also be stabilised aerobically by increasing the aerobic sludge age<br />

to an extent where organic material is aerobically degraded and mineralised. This is<br />

practically done simultaneously in the aeration tank in small plants (up to 10.000 P.E),<br />

or in a separate aerated stabilisation basin. The aerobic stabilisation process is much<br />

more energy consuming than anaerobic fermentation. Also the de-watering <strong>of</strong> the aerobically<br />

stabilised sludge is more difficult and energy consuming. For this reason aerobic<br />

stabilisation is only applied in small treatment plants. (up to 10.000 – 25.000 PE).<br />

Supernatant liquids and process water<br />

The supernatant liquids from all processes for thickening (static thickeners, mechanical<br />

de-watering) are usually charged with high loads <strong>of</strong> nutrients and also COD. For that<br />

reason different strategies for adding the waters to the plant or even for separate treatment<br />

are applied.<br />

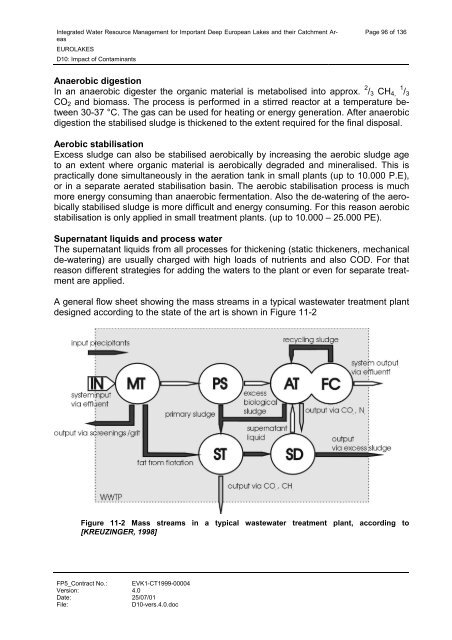

A general flow sheet showing the mass streams in a typical wastewater treatment plant<br />

designed according to the state <strong>of</strong> the art is shown in Figure 11-2<br />

Figure 11-2 Mass streams in a typical wastewater treatment plant, according to<br />

[KREUZINGER, 1998]